Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

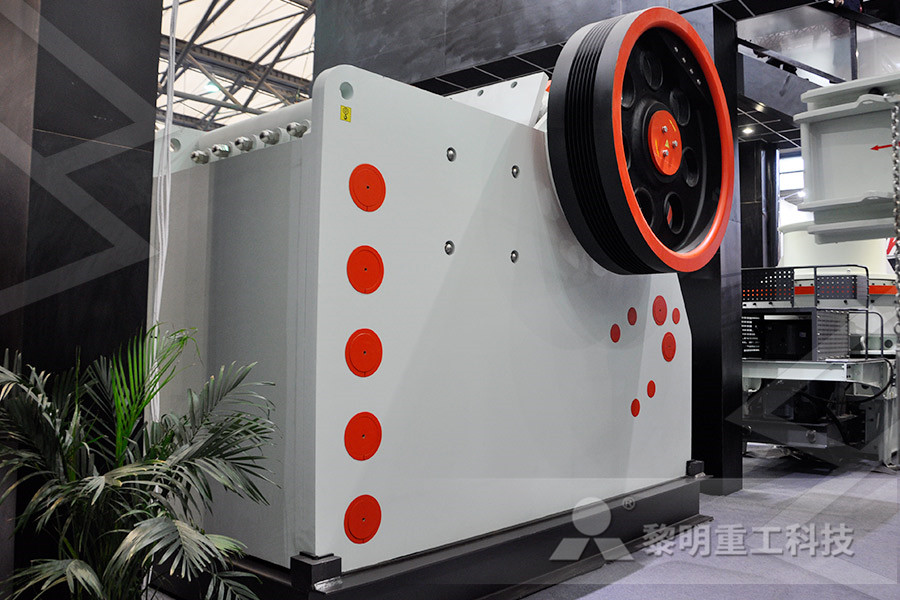

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Roasting (metallurgy) Wikipedia

Roasting is a process of heating of sulphide ore to a high temperature in presence of air It is a step of the processing of certain oresMore specifically, roasting is a metallurgical process involving gas–solid reactions at elevated temperatures with the goal of purifying the metal component(s) Often before roasting, the ore has already been partially purified, eg by froth Process of Iron Smelting Followed by An important roasting process is the oxidation cement mill trunnion bearing parts new machine mineral processing equipment MINERAL PROCESSING Outotec offers partial roastingmineral roasting process and equipmentIn oxidation roasting, the sulfide ore is first decomposed into lowvalence sulfide and sulfur, and then the oxide is formed The oxidation roasting of some sulfide ores is exothermic Oxidation roasting equipment includes a rotary kiln, a multichamber baking furnace, and fluidized baking furnace (see fluidized roasting)Roasting an overview ScienceDirect TopicsAND GOLDBEARING SULFIDE MINERALS Dead roasting is the most commonly used roasting process and is mainly applied in our zinc and pyrite roasters When using a deadroasting process for concentrates, the sulfides are completely transformed into oxides The gas temperature in this type of plant is typically between 800 and 950°C The hot gas OUTOTEC ROASTING SOLUTIONSThe primarily used equipment in crushing are jaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, usually closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plantMineral processing Wikipedia

Mineral Processing Systems and Equipment Bepex

MINERAL INDUSTRY Bepex has long been supplying continuous mineral processing systems Our origins in the mineral industry date back to the 1920s, with the production of briquetting presses used in the coal industryThe products gained from the roasting process are calcine and roasting gas The calcine consists of Fe2O3, Fe3O4, FeSO4 and gangue material, while the roasting gas has SO2, SO3, O2, N2 and H2O as steam Depending on the chlorine content in the roaster feed, HCl may also exist in the roasting gas in corresponding concentrationsPYRITE ROASTING, AN ALTERNATIVE TO SULPHUR BURNING M Mineral Roasting Kilnis a cylindrical vessel, slightly inclining it to the horizontal position, which is rotated slowly toward its axis The material to be processed is fed into the upper end of the cylinder As the Mineral Roasting Kiln rotates, material gradually moves down towards the lower end, and may undergo a certain amount of stirring and Mineral Roasting Kiln – Zonelion Taeda Rotary and mineral industry is very conservative when it comes to introducing new technology which represents a “quantum leap” This also applies to mineral processing equipment which is normally located at the point of extraction Production of concentrate significantly reduces the volume of material that needs to be transportedMineral Processing DECHEMA01022021 Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy Mineral processing metallurgy Britannica

Mineral Processing Systems and Equipment

MINERAL INDUSTRY Bepex has long been supplying continuous mineral processing systems Our origins in the mineral industry date back to the 1920s, with the production of briquetting presses used in the coal industryThe primarily used equipment in crushing are jaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, usually closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plantMineral processing Wikipediaroasters When using a deadroasting process for concentrates, the sulfides are completely transformed into oxides The gas temperature in this type of plant is typically between 800 and 950°C The hot gas generated in the process is used for heat recovery and is suitable for highpressure steam production in a wasteheat boiler For goldroasting applications, even low OUTOTEC ROASTING SOLUTIONSOutotec roasting solutions are based on decades of experience in developing processing technologies for concentrates and ores Safe, easy, and costefficient to operate, they offer low waste generation and high availabilityRoasting OutotecRZPO offers Roasting equipment, Pig roasting equipment In addition, it has a double thermal insulation, consisting of mineral wool up to 80 mm thick The chamber uses high cheese and vegetable processing Under our brand we manufacture a wide range of process equipment such as: Smoking, defrost climate and thermal Roasting equipment Pig roasting equipment

Mineral Roasting Kiln – Zonelion Taeda Rotary

Mineral Roasting Kilnis a cylindrical vessel, slightly inclining it to the horizontal position, which is rotated slowly toward its axis The material to be processed is fed into the upper end of the cylinder As the Mineral Roasting Kiln rotates, material gradually moves down towards the lower end, and may undergo a certain amount of stirring and From the mechanical and process engineering perspective, Ger man mineral processing equipment suppliers belong to the world market elite (eg pressure filters for aluminum refineries, crushers for bituminous sand, high pressure grinding rolls and agitator ball mills for copper and plati num ore etc and mixers and agglomerators for iron ore)Mineral Processing DECHEMA01022021 Alternative Titles: mineral dressing, ore dressing Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyMineral processing metallurgy BritannicaPyrometallurgy is a branch of extractive metallurgyIt consists of the thermal treatment of minerals and metallurgical ores and concentrates to bring about physical and chemical transformations in the materials to enable recovery of valuable metals Pyrometallurgical treatment may produce products able to be sold such as pure metals, or intermediate Pyrometallurgy WikipediaTEMA Process BV is a specialised design and manufacturing company for Fluid Bed Systems for drying of minerals, chemicals, food, feed, biomass, etc The TEMA Fluid Bed can be applied not only for drying, but also for cooling, roasting, torrefaction, puffing, blanching, stripping , spices and herbs sterilisation and pasteurisation and calciningTema Process Fluid bed dryer steam

Roasting Outotec

Outotec roasting solutions are based on decades of experience in developing processing technologies for concentrates and ores Safe, easy, and costefficient to For over 45 years, Multotec has focussed on supplying process technology solutions aimed at reducing the operating costs of mineral processing plants Driven by a global team of process engineers and metallurgical specialists, Multotec designs, builds, manufactures, installs and maintains equipment throughout the entire value chain of mineral processing plants across all commodity sectors Mineral Processing Equipment Multotecprocess,inwhichthematteisground,calcined,and treatedwithcarbonmonoxideat50°Ctoformgaseous equipment 4) explosionandburnhazards—spattersorspillsof MINERAL PROCESSING PLANTS Roasting Smelting Converting Refining Driesoreconcentrate Controlssilicacontent35 MINERAL PROCESSING PLANTS IHSAtural change, process engineering tends to concentrate on whatever technology is at the forefront at any given time such as fine chemicals or biotechnology As a result, a detailed understanding of ore and mineral material parameters and the size of the equipment needed to process them has eroded or disappeared altogetherMineral Processing DECHEMARequest PDF Drying, roasting, and calcining of minerals The papers in this volume give the reader focused information on the important extractive metallurgy unit operations of drying, roasting Drying, roasting, and calcining of minerals

Mineral processing metallurgy Britannica

01022021 Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mining Mineral Processing Coal and other industrial minerals are mined and processed from raw material to finished, marketable commodities PHOENIX provides mining and mineral processing technology to mineral process circuits for the classification, separation and dewatering of minerals and water recycling and dewatering technologies for waste managementMining and Mineral Processing – PHOENIX 15062020 In order to ascertain the change of ore microstructure and mineral composition during fluidized roasting process, the magnetic concentrate and magnetic tailings obtained under the optimized conditions were analyzed by SEMEDS The results are shown in Figs 6 and 7, respectively Download : Download highres image (1MB)Separation of manganese and iron for lowgrade coffee processing equipment and coffee manufacturing solutions are used worldwide From green beans, cleaning, sorting, handling, roasting and grinding to ground coffee, our customized solutions cover small, medium or largescale operationsCoffee Processing Equipment Coffee 29012021 Ilmenite is a vital raw material for the production of metal titanium and titaniumcontaining materials In this paper, microstructure and chemical transformation of natural ilmenite in air atmosphere were investigated by the analysis of XRF, Xray diffractometer, and SEMEDS Results showed that the untreated ilmenite had three layers after oxidation at 800 deg;C for 60 min, which were Fe2O3 Minerals Free FullText Microstructure and