Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

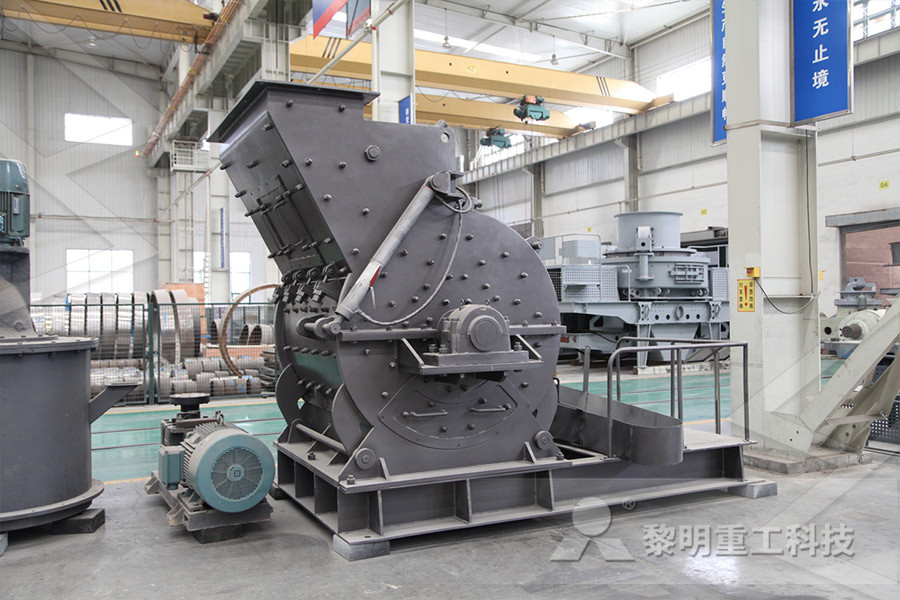

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Cone crusher basics in 4 minutes — Sandvik Mining and Rock

The Sandvik CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher Sampling is a vital part of the crushing process, to ensure that you know the The crusher prevents excessive oil temperature The temperature of the hydraulic system of the hydraulic cone crusher is generally suitable in the range of 35 °C 60 °C according to the experiment, and the maximum should not exceed 80 °C At normal oil temperatures, the crusher hydraulic oil has a Maintenance of Hydraulic System of Cone Crusher (2 When the cone crusher is running, the temperature of the hydraulic oil should meet the requirements of the equipment 5 The particle size of the broken material should meet the requirements of product specifications The feed should pass through the distribution board, and the feed speed should not be higher than the horizontal level of the What to pay attention to when the cone crusher starts cone crusher what temperature is running Cone Crusher What Temperature Is Runningbauecoeu jaw crusher running temperature Systems 5 Kubriamatic is a compact and reliable control and monitoring system especially designed for Kubria cone crushers Get More Info Get priceCone Crusher What Temperature Is RunningTo make sure that your crusher is delivering the desired product, and maximizing its efficiency and productivity, there are a few potential issues that you should be alert to At Sandvik we have researched the factors that – if not properly addressed – can cause cone crushers What affects cone crusher performance? — Sandvik Mining

The Common Questions of Cone Crusher and Corresponding

Nov 25, 2019 Q3: What are the differences between the short, middle and standard types of cone crushers? The differences between short, medium and standard types of cone crusher 1 Different in the crushing cavity The parallel band of short type cone crusher is the longest, the medium one is the second, and the standard one is the shortest 2Aug 15, 2012 Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing chamber Cone crusher has a less steep crushing chamber and more parallel zone between crushing zonesCone Crusher Working Principle Animation Engineering The cone crusher is a modified gyratory crusher The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 82) Power is transmitted from the source to the countershaft to a Vbelt or direct driveCone Crusher an overview ScienceDirect TopicsParts are easy to find, and maintenance is straightforward Carminex carries a full stock of jaw crusher parts to keep your machines up and running Performing simple maintenance will ensure that your jaw crushers provide longterm value Introducing the Cone Crusher Cone crushers take care of secondary and tertiary crushing applicationsJaw Crusher vs Cone Crusher: A ComparisonApr 15, 2020 The table is based on using an HP400 cone crusher, 400 horsepower drive motor, operating at a 1/2” (13mm) closed side setting, running at 80% rated power (320 HP), crushing 250 STPH, operating 8 hours per day, 5 days per week and 50 weeks per year5 tips for energy efficient and productive cone crushing

How to prevent the oil temperature of the cone crusher

The temperature of the hydraulic system of the hydraulic cone crusher is generally suitable in the range of 35 ° C to 60 ° C, and should not exceed 80 ° C Under normal oil temperature, various performances of the hydraulic oil of the crusher are goodTo make sure that your crusher is delivering the desired product, and maximizing its efficiency and productivity, there are a few potential issues that you should be alert to At Sandvik we have researched the factors that – if not properly addressed – can cause cone crushers What affects cone crusher performance? — Sandvik Mining When the cone crusher is running, the temperature of the hydraulic oil should meet the requirements of the equipment 5 The particle size of the broken material should meet the requirements of product specifications The feed should pass through the distribution board, and the feed speed should not be higher than the horizontal level of the What to pay attention to when the cone crusher starts IC7000 HP cone crusher automation English cone IC7000 monitors cone lubrication (oil flow and temperature) making sure that the crusher is always running under ideal conditions IC7000 is operating temperature for crusher"Uncontrollable High speed" is the fault phenomenon of cone crusher, refers to that in the production process, the rotating speed of cone crusher's moving cone suddenly increases, the body suddenly generates violent vibration, the safety spring or the safety cylinder is in abnormal working state, the working current increases instantly, and the oil return temperature rises sharplyUncontrollable High speed of Cone crusher Luoyang Dahua

jaw crusher running temperature parketcorneilliebe

jaw crusher running temperature GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material reduction requirementsjaw crusher bearing temparature Exodus Heavy Jaw Crusher Work material is crushed between two opposing jaw plates One plate opens and shuts crushing raw material against the stationary jaw plate Cone Crusher Material is fed into the crusher cavity and processed by the eccentric rotating action of the inner cone against the outer cone Work can be reduced to a diameter ranging from 50 mm to jaw crusher working temperature geboortespandoekeu1 Before starting, all jaw crusher parts must be fastened installed The tail traction spring is suitable loose, and the engine oil is installed in the swing bolster 2 Jaw rock crusher must test run 2 hours when first startup It can be fed to work after the bolster temperature Jaw Crusher Handbook Stone Crusher PDF JXSC MineParts are easy to find, and maintenance is straightforward Carminex carries a full stock of jaw crusher parts to keep your machines up and running Performing simple maintenance will ensure that your jaw crushers provide longterm value Introducing the Cone Crusher Cone crushers take care of secondary and tertiary crushing applicationsJaw Crusher vs Cone Crusher: A ComparisonPr imar y cr ushi ng reduces thi s run of mine r ock to a more manageable size The different types of primary crushers are: jaw crushers, gyratory crushers, impact crushers, and autogenous crushers JAW CRUSHER The jaw crusher squeezes rock between two surfaces, one of which opens and c loses like a jaw Rock enters the jaw crusher from the topSAND, GRAVEL, AND CRUSHED STONE ONTHEJOB

Tips for maintaining efficiency in crushing circuits – Quarry

Jan 04, 2019 Be especially careful that a cone crusher does not get ring bounce or chatter Variable flow controlled by level sensors will ensure consistent feeding and maintain a full crushing chamber Low oil temperature should prevent operation of the unit High oil temperature should stop the crusher feed and allow the unit to cool downA jaw crusher crushes only a small proportion of the original aggregate particles but an impact crusher crushes mortar and aggregate particles alike and thus generates a higher amount of fine material (O’Mahony, 1990) Gyratory crushers work on the same principle as cone crushers (Figure 44(c)) These have a gyratory motion driven by an Impact Crusher an overview ScienceDirect TopicsCrusher cavityincluded; Accumulator certificationstandard; Ambient temperaturenormal condition down to 15°C; Motor Grooves type8V; Quantity of motors1 each; Motor suppliercustomer; Motor voltage460V; Motor housingIEC; Motor speed/pole number4 (1500rpm 50Hz/1800rpm 60Hz) Countershaft speed1,050 1/min; Crusher pulley size630mm 1144 Omnicone Used/Certified Crushers Apr 15, 2020 The table is based on using an HP400 cone crusher, 400 horsepower drive motor, operating at a 1/2” (13mm) closed side setting, running at 80% rated power (320 HP), crushing 250 STPH, operating 8 hours per day, 5 days per week and 50 weeks per year5 tips for energy efficient and productive cone crushing When the cone crusher is running, the temperature of the hydraulic oil should meet the requirements of the equipment 5 The particle size of the broken material should meet the requirements of product specifications The feed should pass through the distribution board, and the feed speed should not be higher than the horizontal level of the What to pay attention to when the cone crusher starts

How to prevent the oil temperature of the cone crusher

The temperature of the hydraulic system of the hydraulic cone crushe r is generally suitable in the range of 35 ° C to 60 ° C, and should not exceed 80 ° C Under normal oil temperature, various performances of the hydraulic oil of the crusher are goodIC7000 HP cone crusher automation English cone IC7000 monitors cone lubrication (oil flow and temperature) making sure that the crusher is always running under ideal conditions IC7000 is operating temperature for crusherCone Crusher PAGES 26 37 • Cone Liner Selection • Cone Liner Profiles • Run the Chamber at an optimum speed Running it too fast will hinder the liners Moisture, Temperature CRUSHER SETTINGS Speed, CSS FEED Rock Type, Size, Shape, Hardness, Toughness WEARR Crusher Wear Parts Reference GuideJan 04, 2019 Be especially careful that a cone crusher does not get ring bounce or chatter Variable flow controlled by level sensors will ensure consistent feeding and maintain a full crushing chamber Low oil temperature should prevent operation of the unit High oil temperature should stop the crusher feed and allow the unit to cool downTips for maintaining efficiency in crushing circuits – QuarryJaw rock crusher must test run 2 hours when first startup It can be fed to work after the bolster temperature below 600 After that, a startup can work 3Jaw Crusher Handbook Stone Crusher PDF JXSC Mine

Cone Crusher Working Principle Animation Engineering

Aug 15, 2012 Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing chamber Cone crusher has a less steep crushing chamber and more parallel zone between crushing zonesApr 28, 2017 Trickle feeding a cone crusher should be avoided because it not only results in poor productivity and poor product shape, but it can also adversely affect bearing alignment within said crusher Due to the operational characteristics of a cone crusher, when crushing, it should never be operated below 40 percent rated horsepowerMaximize your cone crusher productivity : Pit QuarryA jaw crusher crushes only a small proportion of the original aggregate particles but an impact crusher crushes mortar and aggregate particles alike and thus generates a higher amount of fine material (O’Mahony, 1990) Gyratory crushers work on the same principle as cone crushers (Figure 44(c)) These have a gyratory motion driven by an Impact Crusher an overview ScienceDirect TopicsMetallurgical ContentGyratory CrushersGyratory Crusher Capacity TablesSmall Gyratory Crusher Capacity ChartCrusher DriveGyratory CrusherEccentricity Adjustable to Capacity Demands ADVANTAGES OF BOTTOM DISCHARGELOW OPERATING COSTS VERTICAL ADJUSTMENTSMETHODS OF VERTICAL ADJUSTMENTGyratory Crusher Spider Gyratory Crushers Mineral Processing Metallurgy® HP Series™ cone crushers are reliable rock crushing machines for all demanding quarrying, mining, and tunneling applications Over the years they have become the most popular modern cone crushers in the world with over 10,000 machines sold globally® HP Series™ cone crushers