Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

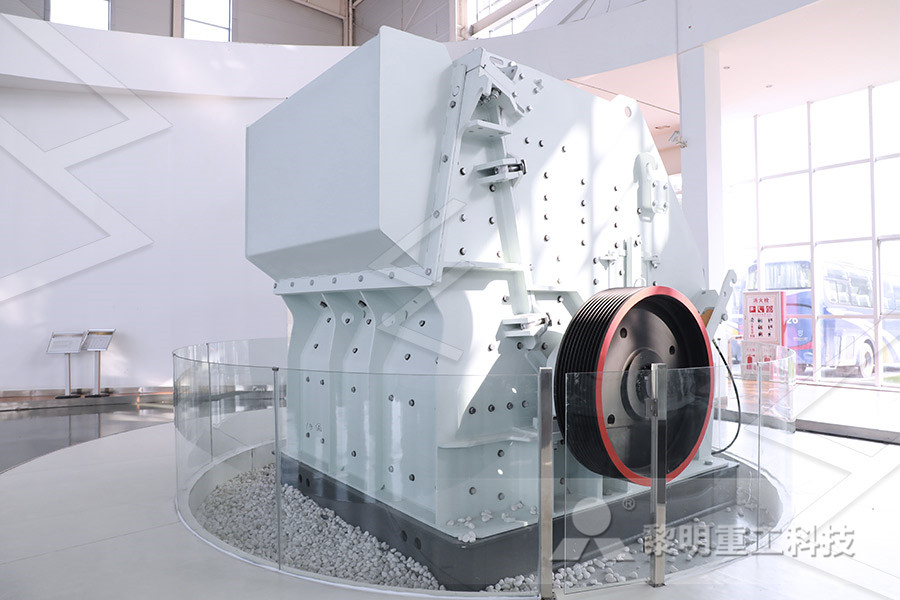

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

FiveStage Deinking Flotation Cell (Complete Closed) FJLIME

FiveStage Deinking Flotation Cell (Complete Closed) The five stage deinking flotation cell is designed for deinking purpose With reliable quality and economical price, it is widely used in waste paper recycling and paper making industries Specifications of FiveStage Deinking Flotation CellFiveStage Deinking Flotation Cell (Complete Closed) The five stage deinking flotation cell is designed for deinking purpose With reliable quality and economical price, it is widely used in waste paper recycling and paper making industries Specifications of FiveStage Deinking Flotation CellFiveStage Deinking Flotation Cell (Complete Closed five stage complete closed flotation cell Fivestage deinking flotation cell complete closed fivestage deinking flotation cell complete closed the five stage deinking flotation cell is designed for deinking purpose with reliable quality and economical price it is widely used in waste paper recycling and paper making industries specifications of eco pulp making deinking flotation cell production linedeinking flotation cell convection deinking flotation fjlime is china deinking flotation cell manufacturer five stage deinking flotation cell is designed for deinking purpose with reliable quality and economical price it is used in waste paper recycling and paper making industries layers 4 5 stock consistency 1 12 Learn MoreEco Pulp Making Deinking Flotation Cell Production LinePulp Making FiveStage Complete Closed Deinking Flotation Cell, production line Fujian Light Industry Machinery Equipment Co, Ltd US $5000$ / UnitChina Deinking Pulp, China Deinking Pulp Manufacturers and

PULP PAPER Selecta Flot DEINKING FLOTATION

to the flotation cells and the accept flow from the secondary stage allows stable operation without any undesirable variations in performance SelectaFlot flotation inline arrangement Efficient deinking is primarily about two things: how to maximize brightness while Alibaba offers 362 deinking pulp products About 35% of these are Paper Processing Machinery, 4% are Paper Machinery Parts A wide variety of deinking pulp options are available to you, such as type, computerizeddeinking pulp, deinking pulp Suppliers and Manufacturers Although, the deinking of paper pulp is usually conducted in a flotation cell with agitation, into which air is injected countercurrent to the feed Recent studies have focused on columns without Deinking of recycled pulps using column flotation: Energy Delivery comprised a new preflotation primary cell “Street 3” parallel to the existing old cells and a new secondary stage cell (common for all preflotation primary cells) designed for 158 t/d capacity The space was limited to 11 meters x 75 meters, where the cells were built while production was running The rebuilt pulp line manufacturesdeinking technology Floating to the Top pulp and paper negligible foaming ability under the conditions of the Ross Miles standard) A proprietary commercial flotation deinking aid intended for mixed office recovered paper based on a nonionic surfactant blend was used as a comparison (425 mm Ross Miles foam at 5 min (01%, 25 ºC in DI water)Natural Surfactants for Flotation Deinking in Paper Recycling

FiveStage Deinking Flotation Cell (Complete Closed

FiveStage Deinking Flotation Cell (Complete Closed) The five stage deinking flotation cell is designed for deinking purpose With reliable quality and economical price, it is widely used in waste paper recycling and paper making industries Specifications of FiveStage Deinking Flotation CellDeinking Machine,Deinking Flotation Cell,Convection The deinking machine features little loss of fibers The waste water with little ink is easy to deal with FiveStage Deinking Flotation Cell (Complete Closed)The five stage deinking flotation cell is designed for deinking purposeflotation deinking cell for mining AIPSAlthough, the deinking of paper pulp is usually conducted in a flotation cell with agitation, into which air is injected countercurrent to the feed Recent studies have focused on columns without Deinking of recycled pulps using column flotation: Energy Delivery comprised a new preflotation primary cell “Street 3” parallel to the existing old cells and a new secondary stage cell (common for all preflotation primary cells) designed for 158 t/d capacity The space was limited to 11 meters x 75 meters, where the cells were built while production was running The rebuilt pulp line manufacturesdeinking technology Floating to the Top pulp and paper Jun 19, 2003 A flotation deinking process with a partially closed water loop was simulated at the pilot plant scale adopting the plant sketch shown in Fig 1The pulper was fed with a 60% old newsprint (ONP) (30% flexo and 30% offset) and a 40% old magazines (OMG) mixture together with conventional deinking chemicals, ie a sodium soap collector, sodium hydroxide, hydrogen peroxide and sodium Dynamic surface tension of flotation deinking systems

Closed floatation deinking module for recycled paper

May 26, 2009 Referring to FIG 3, shown is a flow chart of the closed deinking module of the present invention As aforementioned, the pulp slurry source 12 has feed line 14 and feed line flow control 16 that provides flotation cell 24 with pulp slurry Flotation cell 24 can incorporate vacuum break 26 and/or waterproof camera 28 and/or sight glass 30Deinking of secondary fibers involves dislodging ink particles from fiber surfaces and separating dispersed ink from fiber suspensions by washing or flotation Enzymatic approaches involve attacking either the ink or the fiber surfaces Different enzymes have been used for deinking, including lipases, esterases, pectinases, hemicellulases, cellulases, and ligninolytic enzymesDeinking an overview ScienceDirect TopicsThe deinking selectivity obtained for a twostage preflotation system was in agreement with data collected in a deinking mill running in similar conditions and process yield, floated pulp Parameters of Deinking Efficiency in an Industrial Zcf Series Diffusion Deinking Flotation Machine Buy ZCF series diffusion deinking flotation machine consists of steel cylindrical flotation cell, step diffusion stockair mixer, annular stock inlet pipe, center reject pipe and level control box, etcNormally, ZCF series diffusion deinking flotation machine can be used as in cascade of 5~ 7 cells or secondary stage flotation for recovering Zcf Diffusion Deinking Flotation CellFiveStage Deinking Flotation Cell (Complete Closed) With reliable quality, easy operation and simple maintenance, this press washer is very popular with customers from 名门棋牌游戏大厅下载

Flotation Column: A Process Unit for Cleaning Up Paper

contaminants from pulp [12] There is a wide variety of flotation cells available for deinking but the dominant technology typically consists of multiple horizontal flotation cells in series, with each cell being aerated by several injectors To reduce fibre losses, flotation rejects of this primary stage are generally treated in secondary The present invention relates to a process for deinking waste paper comprising treating the waste paper with a peroxide compound in an aqueous alkaline medium in the presence of a first polymer (A) comprising a Cabinding polymer in the form of a polycarboxylate polymer and a second polymer (B) comprising a polyalfahydroxyacrylic acid or a salt thereof or the corresponding polylactone, said USB2 Process for deinking waste paper Google procedure was used to run flotation trials Specifically, after filling the flotation cell with the pulp suspension with a constant pulp flow of 25 L/min, a gas flow of 5 L/min was injected in the cell via Venturi aerators and the froth removal thickness was adjusted to 2 cm Floated pulp samples were collected every 2 min during 16 minASSESSMENT OF DEINKING CHEMISTRY PERFORMANCE: A process for deinking recycled paper using a pressurized deinking module to separate ink from paper pulp stock The addition of salts of imidazolinium based compounds with alkyl, alkenyl and amidoethyl side chains to the pulp slurry at the beginning of the pressurized deinking module cycle removes ink more effectively and results in a brighter recycled paper and an increase in yield of final USA Process for deinking of recycled paper contaminants from pulp [12] There is a wide variety of flotation cells available for deinking but the dominant technology typically consists of multiple horizontal flotation cells in series, with each cell being aerated by several injectors To reduce fibre losses, flotation rejects of this primary stage are generally treated in secondary Flotation Column: A Process Unit for Cleaning Up Paper

Deinking Kadant Inc

The operating principle is based on the combined multistage effect of the MACCell tank flotation principle and column flotation using different shape characteristics and counterflow effects Due to its unique design, the MAKC can absorb feed quality variation, based on specific furnish critieria , without negatively impacting performanceApr 21, 2010 The pulp containing secondary fibers needs to be purified in a deinking installation A total closed water system is developed for water reclamation in deinking installations The pulp with inks is first processed with an induced (dispersed) air flotation (IAF) cell and then a Completely Closed Water Systems in Paper Mills SpringerLinkJun 19, 2003 A flotation deinking process with a partially closed water loop was simulated at the pilot plant scale adopting the plant sketch shown in Fig 1The pulper was fed with a 60% old newsprint (ONP) (30% flexo and 30% offset) and a 40% old magazines (OMG) mixture together with conventional deinking chemicals, ie a sodium soap collector, sodium hydroxide, hydrogen peroxide and sodium Dynamic surface tension of flotation deinking systems procedure was used to run flotation trials Specifically, after filling the flotation cell with the pulp suspension with a constant pulp flow of 25 L/min, a gas flow of 5 L/min was injected in the cell via Venturi aerators and the froth removal thickness was adjusted to 2 cm Floated pulp samples were collected every 2 min during 16 minASSESSMENT OF DEINKING CHEMISTRY PERFORMANCE: A process for deinking recycled paper using a pressurized deinking module to separate ink from paper pulp stock The addition of salts of imidazolinium based compounds with alkyl, alkenyl and amidoethyl side chains to the pulp slurry at the beginning of the pressurized deinking module cycle removes ink more effectively and results in a brighter recycled paper and an increase in yield of final USA Process for deinking of recycled paper

Closed floatation deinking module for recycled paper

May 26, 2009 Referring to FIG 3, shown is a flow chart of the closed deinking module of the present invention As aforementioned, the pulp slurry source 12 has feed line 14 and feed line flow control 16 that provides flotation cell 24 with pulp slurry Flotation cell 24 can incorporate vacuum break 26 and/or waterproof camera 28 and/or sight glass 30flotation is continued longer than five minutes 124 KONA No23 (2005) 02 46 8 Ash Content, % Flotation time, min 0 2 4 6 8 10 12 14 16 18 Fig 2 Effect of flotation time on ash content of deinked pulp (05% H 2O 2, 01% NH 4OH, 2 minutes pulping) 12 345 67 Flotation Time, Min Yield, % 82 84 86 88 90 92 94 Fig 3 Effect of flotation time on Separation of Ink Particles from Waste Paper by FinebubblesThe present invention relates to a process for deinking waste paper comprising treating the waste paper with a peroxide compound in an aqueous alkaline medium in the presence of a first polymer (A) comprising a Cabinding polymer in the form of a polycarboxylate polymer and a second polymer (B) comprising a polyalfahydroxyacrylic acid or a salt thereof or the corresponding polylactone, said USB2 Process for deinking waste paper Google Vertical Flotation Deinking Cell Buy Vertical flotation Vertical Flotation Deinking Cell Application It used for removing the dust and ink particles in the waste paper pulp,so as to get high quality paper pulp Advantage Higher whiteness of pulp and other ash removal can be obtained than other flotation deinking devices Live Chatvertical flotation cell equipmentInjectaCell Compact achieves high savings in investment and maintenance in flotation through eliminating the secondary flotation cell the stock consistency is increased from about 5 to 30% or more to prepare for the next process stage and for complete water loop separation This is a precondition for efficient deinking in flotation BlueLine Voith

Effects of sequencing enzyme application and refining on

In the deinking stage, no significant changes were observed in the tear strength The tear strength reduction after the RE stages was 15% lower than after the ER stages After deinking with the RED method, the average amount of tear strength was 285% and 214 % higher than with the ERD method at 700 and 1500 revolutions of refining, respectivelyFlotation Research by Deng and Zhu at the Institute of Paper Science and Technology has resulted in a novel modification of conventional flotation deinking (2) Their approach is to introduce the frothing agent as a spray applied only to the upper surface of the pulp slurry in the flotation cell rather than incorSemiannual Patents Review Janurary—June 1999May 24, 2014 In general flotation is effected at approx 1,2 % inlet consistency In a standard layout design the SelectaFlot™ flotation cells are arranged in series, with 5 cells in the primary and 2 cells in the secondary stage as standard design For the reduction of fiber loss, a secondary flotation stage treats the foam of the primary stageFlotation MyViet IDI