Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

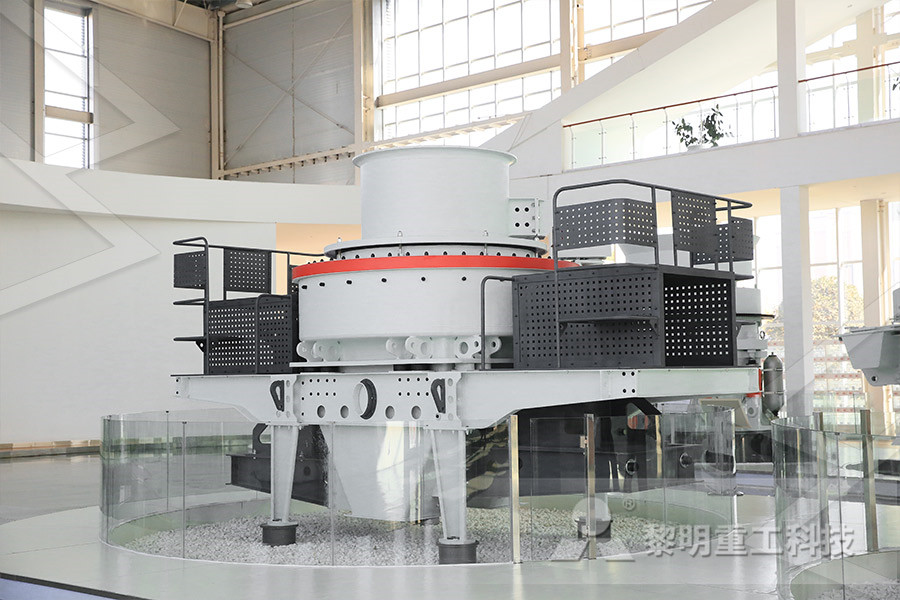

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Division of Operation and Maintenance Engineering Decision

cost, but also the mill revenue due to variation in the metal output Therefore, the production performance has to be considered when developing decision models for making maintenance replacement policies for mill liners Variation in the ore properties also affects the liner wear and ore • Mill linings shell, feed and discharge heads • Parts supplied and required Outputs and resulting actions The condition and required action is evaluated for every procedure The findings are summarised in Outotec’s mill inspection report Outotec’s mill specialist evaluates the maintenance status of the equipment and gives feedbackOUTOTEC MAINTENANCE INSPECTION FOR GRINDINGlargescale mills, there is little information on smallscale mill technologies and on how to make the right purchase decision This working document includes information on various types of hullers and small mills available in Africa It advises how to select milling equipment, and how to install, operate and maintain small millsSmall mills in Africa Food and Agriculture Organization26112013 ball mill maintenance pdf crusher mobile ball mill operation pdf manganese crusher ball mill operator duties 10, 2004 40 inspect the ball mill cont operation maintenance of a ball mill pdf ball mill operation and maintenance pdf ore beneficiation plant usa ball mill for sale, ball mill operation and maintenance usa ball mill operation andball mill operation and maintenance pdf 29031999 to how maintenance can be performed to ensure equipment reaches or exceeds its design life have been developed in the United States In addition to waiting for a piece of equipment to fail (reactive maintenance), we can utilize preventive maintenance, predictive maintenance, or reliability centered maintenance 52 Reactive MaintenanceChapter 5 Types of Maintenance Programs Energygov

Crushing Plant Design and Layout Considerations

in ore characteristics, size distribution, moisture content, ore grade and climatic conditions • Operators have always dreamed of reducing the need for crushing equipment; when SAG mills were first introduced, it was hoped that they would eliminate secondary and tertiary circuitsMetallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound Ball Mill Maintenance Installation Proceduremaintenance and nonmaintenance related downtime Nonmaintenance related downtime may be attributed to lack of demand, an interruption in raw material supply or production scheduling delays beyond the control of the maintenance function Asset utilization is also a function of operating rate, quality and yield losses, etcKEY PERFORMANCE INDICATORS Plant Maintenance18102020 There is still gold in this underground mine! We have found a spot at our gold mine where the old miners left rich ore and we are going to get it out and crGold Mine High Grading, Hammer Mill cost, but also the mill revenue due to variation in the metal output Therefore, the production performance has to be considered when developing decision models for making maintenance replacement policies for mill liners Variation in the ore properties also affects the liner wear and ore Division of Operation and Maintenance Engineering Decision

MF2041 Preventative Maintenance for Feed Processing

3 Equipment maintenance requirements 4 Parts inventory 5 Maintenance records Equipment Identification At some point, every piece of equipment in the feed mill will need maintenance of some type In order to track the frequency of maintenance needed and its type and cost, each piece of equipment must be identified in some manner Each piece • Mill linings shell, feed and discharge heads • Parts supplied and required Outputs and resulting actions The condition and required action is evaluated for every procedure The findings are summarised in Outotec’s mill inspection report Outotec’s mill specialist evaluates the maintenance status of the equipment and gives feedbackOUTOTEC MAINTENANCE INSPECTION FOR GRINDINGin ore characteristics, size distribution, moisture content, ore grade and climatic conditions • Operators have always dreamed of reducing the need for crushing equipment; when SAG mills were first introduced, it was hoped that they would eliminate secondary and tertiary circuitsCrushing Plant Design and Layout Considerationsmaintenance and nonmaintenance related downtime Nonmaintenance related downtime may be attributed to lack of demand, an interruption in raw material supply or production scheduling delays beyond the control of the maintenance function Asset utilization is also a function of operating rate, quality and yield losses, etcKEY PERFORMANCE INDICATORS Plant MaintenanceAn Introduction to Total Productive Maintenance (TPM) J Venkatesh ( venhal@yahoo ) In today’s industrial scenario huge losses/wastage occur in the manufacturing shop floor This waste is due to operators, maintenance personal, process, tooling problems and nonavailability of components inAn Introduction to Total Productive Maintenance (TPM)

Ball Mill Maintenance Installation Procedure

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound Maintenance is doing, what it is achieving for the business and what more it can do to improve operational performance Maintenance performance can be improved by making it more effective and more efficient Effective maintenance is doing the right maintenance: that which brings higher equipment reliability and lower operational risksUseful Key Performance Indicators for Maintenance16102020 Mill Toolholding Milling Holemaking Threading Lathe Tooling Tooling Accessories Mill Workholding Tool Kits Apparel Accessories Contact Us Keep your Haas machines running at peak performance while avoiding unplanned downtime A maintenance program allows you to manage your schedule rather than getting caught with untimely VMC Maintenance Schedule Haas AutomationThe transition process of implementation standard for environmental management system (EMS) ISO 14001 :2015 lasts for three years, requiring every organization to (PDF) THE TRANSITIONAL CHANGE ON THE 3 Equipment maintenance requirements 4 Parts inventory 5 Maintenance records Equipment Identification At some point, every piece of equipment in the feed mill will need maintenance of some type In order to track the frequency of maintenance needed and its type and cost, each piece of equipment must be identified in some manner Each piece MF2041 Preventative Maintenance for Feed Processing

OUTOTEC MAINTENANCE INSPECTION FOR GRINDING

• Mill linings shell, feed and discharge heads • Parts supplied and required Outputs and resulting actions The condition and required action is evaluated for every procedure The findings are summarised in Outotec’s mill inspection report Outotec’s mill specialist evaluates the maintenance status of the equipment and gives feedbacklargescale mills, there is little information on smallscale mill technologies and on how to make the right purchase decision This working document includes information on various types of hullers and small mills available in Africa It advises how to select milling equipment, and how to install, operate and maintain small millsSmall mills in Africa Food and Agriculture Organizationin ore characteristics, size distribution, moisture content, ore grade and climatic conditions • Operators have always dreamed of reducing the need for crushing equipment; when SAG mills were first introduced, it was hoped that they would eliminate secondary and tertiary circuitsCrushing Plant Design and Layout Considerations29031999 to how maintenance can be performed to ensure equipment reaches or exceeds its design life have been developed in the United States In addition to waiting for a piece of equipment to fail (reactive maintenance), we can utilize preventive maintenance, predictive maintenance, or reliability centered maintenance 52 Reactive MaintenanceChapter 5 Types of Maintenance Programs EnergygovRoller Mill Maintenance Roller mills are used around the feed mill to perform a variety of tasks Applications include crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted feeds While each application has some uniqueRoller Mill Maintenance00 CPM

RioTintoIronOreTrain Wheel MaintenanceLangham

Optimizing the Maintenance Program for Rio Tinto Iron Ore’s Train Wheels Karl Langham Melinda Hodkiewicz School of Mechanical and Chemical Engineering John McArthur CEED Client: Rio Tinto Iron Ore Abstract This project was initiated to provide input into a review of Rio Tinto Iron Ore’s ore car wheel set maintenance tacticsmaintenance schedules Note: • The operation and maintenance practices outlined in this document are based on full utilization of GEapproved parts, repairs, and services • The operating and maintenance discussions presented are generally applicable to all GE heavyduty gas turbines; ie, Frames 3, 5, 6, 7, and 9 Appendix G provides a HeavyDuty Gas Turbine Operating and Maintenance Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound engineering principles Ball Mill Maintenance Installation ProcedureMaintenance Metrics Basics determines effectiveness of the maintenance fix shift Turbulence in the flying window creates stress on the flight line—keep the schedule consistent throughout the week A late start on one day affects the next day’s early start Turn times must be negotiated between operations and maintenance and should be Maintenance Metrics Handbook US Air Force