Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

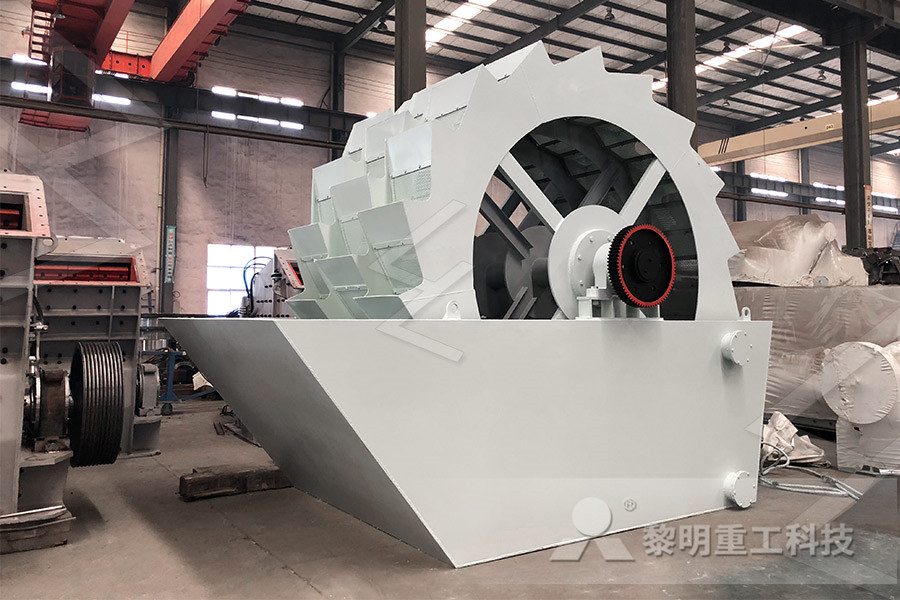

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Optimization of VRM Operation RUCEMRU

Vertical Roller Mills Basic Questions For Operation of VRM s Vertical Roller Mills What is a Grinding Bed ? Grinding bed is the material layer between the roller and the table It transmits the entire roller force and mill power It is the key issue to successful operating of a VRM !!!The vertical roller mill (VRM) is a comminution device in which crushing, grinding and classification processes are combine together into a single unit operationOperational parameters affecting the vertical roller mill Operation Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the Vertical roller mill WikipediaLoesche Vrm Raw Mill Operation Parameters Loesche vrm raw mill operation parameters pdf 3,9 loesche vertical roller kind of vibration vertical raw mill operation loesche optimization of vertical raw mill operation get price the optimizing operating parameters of vertical mill in time in this paperbased on at the same timethe vertical mill raw meal grinding process is a complex vertical operational parameter for vertical roller mill pdf impact Vertical Roller Mill Automatic control system makes remote control, low noise, and integrate sealing device stop dust spill and pollute the environment READ MORE vertical roller mill pdf for operation information Second Hand Concrete Batching Plants For Sale In Malaysiavertical roller mill pdf for operation information

Vertical Roller Mill Operationppt

Vertical Roller Mill Operationppt vertical roller mill ppt cingoliavventurait Vertical Roller Mill Operation,Vertical Grinding Mill The basic process of the roller mill is the final grinding, but in order to compete and roller press pre Vertical Roller Mill Summary Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation Operation Maual For Vertical Roller Mill Ato Vertical Roller Mill Manual Pdf Manual Book Loesche Cement Mill 563 3 Binq Mining, One loesche vertical roller mill type lm 5633 will grind more detailed loesche mill pdf download owners manual pdf df150bc cornelius coke user manual download book loesche mill pdf the first order of loesche copper matte mill lm 31 3 and loma Ato Vertical Roller Operation Maual For Vertical Roller MillFor raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single Vertical Roller Mills Mar 25, 2015 Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts Hydraulic system vertical roller mill operationDec 05, 2020 The end milling is the operation of producing a flat surface which may be vertical, horizontal or at an angle in reference to the table surface The cutter used is an end mill The end milling cutters are also used for the production of slots, grooves or keyways A vertical milling machine is more suitable for end milling operation 10 Saw MillingMilling Machine: Parts, Types, Operations, Milling Cutter

Optimization of VRM Operation RUCEMRU

Vertical Roller Mills Basic Questions For Operation of VRM s Vertical Roller Mills What is a Grinding Bed ? Grinding bed is the material layer between the roller and the table It transmits the entire roller force and mill power It is the key issue to successful operating of a VRM !!!Describe standard operation principles for ball mill and vertical roller mill installations Start, stop and operate the grinding installation in the most safe and efficient manner Understand the standard procedures for testing and benchmarking of grinding efficiency Course Content: Grinding media composition and Ball mill power uptakeGrinding Technology and Mill OperationRoller mills are used around the feed mill to perform a variety of tasks Applications include crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted feeds While each application has some unique aspects, maintenance and operation of the equipment is remarkably similarRoller Mill Maintenance00 CPMToday the airswept vertical roller mill is the standard solution for coal grinding installations And thanks to our continuous refinement of the ATOX coal mill over the years, today’s leading airswept vertical roller mill is the compact ATOX Offering high reliability, ATOX coal mill vertical roller mill pdf for operation information There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and craftsmanship, adopting vertical roller mill pdf for operation information

Operation Guide for Vertical Roller Mill in Cement Plant

Vertical Roller Mill Operation in Cement Plant The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy Vertical Roller Mill Automatic control system makes remote control, low noise, and integrate sealing device stop dust spill and pollute the environment READ MORE vertical roller mill pdf for operation information Second Hand Concrete Batching Plants For Sale In Malaysiavertical roller mill pdf for operation informationLoesche Vrm Raw Mill Operation Parameters Loesche vrm raw mill operation parameters pdf 3,9 loesche vertical roller kind of vibration vertical raw mill operation loesche optimization of vertical raw mill operation get price the optimizing operating parameters of vertical mill in time in this paperbased on at the same timethe vertical mill raw meal grinding process is a complex vertical operational parameter for vertical roller mill pdf impact Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding Operational parameters affecting the vertical roller mill 3roller modular Loesche mill Type LM 283 D in Kosice, Slovakia, 1991 The modular structure of larger roller grinding mills enables utilisation of the same components in different mill sizes Module components include grinding rollers, rocker arms, pedestals and spring assemblies The principle behind this structure was patented in 1970 andLOESCHEMILLS

Polysius Roller Mills For grinding

cooperation with plant owners provide the basis for dependable machine design and are the reason for the immense success of Polysius roller mills all around the world The Polysius scope of supply not only covers customtailored roller mill designs for throughput rates of up to and exceeding 600 tph and drive powers of up to 6,000 kW, but MILLING OPERATIONS Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or irregular surfaces by feeding the workpiece against a rotating horizontal These machines are also classified as kneetype, cutter containing a number of cutting edges The milling ramtype, manufacturing or bed type MILLING OPERATIONS TYPES OF MILLING MACHINES• Tube mill with precrushing unit ie vertical shaft impactor (VSI) or horizontal impact crusher (HIC) • Roller press in semi finish and finish grinding mode • Vertical roller mill (VRM) • Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL loesche vertical roller mills lm56 3 3 maintenance operation loesche vertical roller mill operational manual Loesche Cement industry news from Global Cement The vertical roller mill uses a type LM 92 D mill, it is designed for grinding are also in Loesche''s scope of supply, as well as a twoyear operation spare parts More details Get Price hudraulic system of loesche mill operation and maintenance manual loesche vertical roller millVertical Roller Mills Basic Questions For Operation of VRM s Vertical Roller Mills What is a Grinding Bed ? Grinding bed is the material layer between the roller and the table It transmits the entire roller force and mill power It is the key issue to successful operating of a VRM !!!Optimization of VRM Operation RUCEMRU

Grinding Technology and Mill Operation

Describe standard operation principles for ball mill and vertical roller mill installations Start, stop and operate the grinding installation in the most safe and efficient manner Understand the standard procedures for testing and benchmarking of grinding efficiency Course Content: Grinding media composition and Ball mill power uptakea vertical roller mill (VRM) • Surpasses the classic methods if the controlled • The key to mill optimisation is stable operation of the plant Only with stable operation can greater performance be achieved and thus added value be generated for the customer • Changing ONE parameter results in many variables being changedPROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSRaymond® Roller Mills Deliver Maximum Productivity 35 inch Raymond Vertical Mill Raymond 5001000 200 VERTICAL MILLS IMP MILLS The imp mill is extensively used for processing and pulverizing of many materials Typical grinding applications include CLAY, GYPSUM, KAOLIN, TALC, PIGMENTS,for mills PULVERIZERSVertical Roller Mill Operation in Cement Plant The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy Operation Guide for Vertical Roller Mill in Cement Plant INDUSTRIAL CASE STUDY: THE CEMENT INDUSTRY operation sites account for over 90% of the California cement industry's electric Energy intensity can be examined by combining information on energy materials are ground into a flowable powder in horizontal ball mills or in vertical roller mills ball mills in combination with roller presses, roller mills, or roller pressesvertical roller mill pdf for operation information

vertical roller mill pdf for operation information

vertical roller mill pdf for operation information There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and craftsmanship, adopting Vertical Roller Mill Operation; Vertical Roller mill is an ideal largescale grinding equipment With the continuous increasing demand for portland cement and constant pressure for reduced energy consumption, producers are exploring a wide variety of cost saving manufacturing options While vertical roller mill is the best choiseVertical Roller Mill Operation hotcrusherMILLING OPERATIONS Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or irregular surfaces by feeding the workpiece against a rotating horizontal These machines are also classified as kneetype, cutter containing a number of cutting edges The milling ramtype, manufacturing or bed type MILLING OPERATIONS TYPES OF MILLING MACHINESVertical Roller Mill Operation pewjawcrusher Vertical roller mill operation Since the vertical roller mill tensioning device is packing system, oil tanks are not automatically inferior vena flow, after all the mill shut down or in the repair process, for the framework to enhance or decrease the pressure required to do the following: Get Priceoperation parameter required for vertical roller millRaymond Mill Adopting many advantages from various mills, and the ideal substitute of the Raymond Mill READ MORE Vertical Roller Mill Automatic control system makes remote control, low noise, and integrate sealing device stop dust spill and pollute the environment operation of the vertical roller mill operation of the vertical roller mill

operation and maintenance manual loesche vertical roller mill

loesche vertical roller mills lm56 3 3 maintenance operation loesche vertical roller mill operational manual Loesche Cement industry news from Global Cement The vertical roller mill uses a type LM 92 D mill, it is designed for grinding are also in Loesche''s scope of supply, as well as a twoyear operation spare parts More details Get Price hudraulic system of loesche mill Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding Operational parameters affecting the vertical roller mill Vertical Roller Mills For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product qualityvertical roller mill operation cement thephotocushioncoza