Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

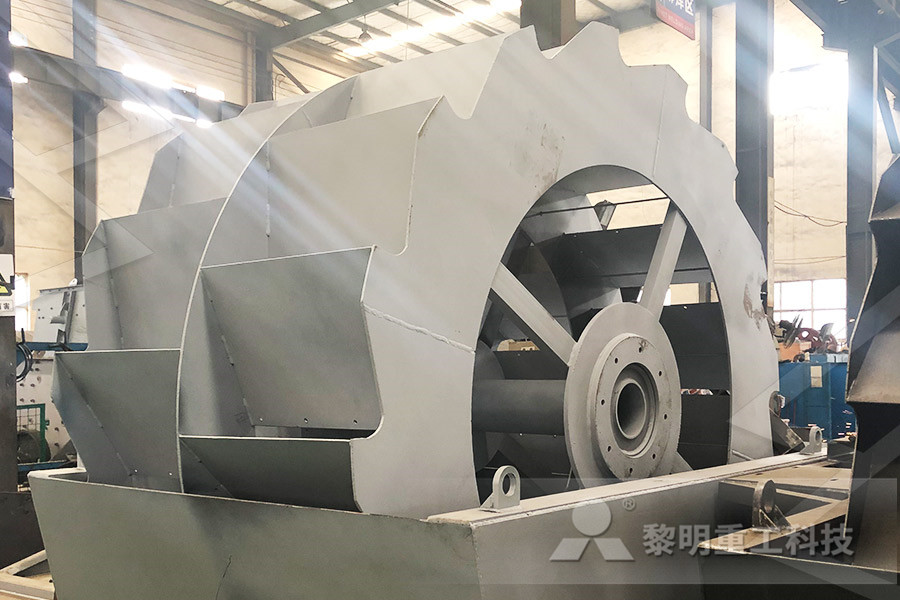

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Polishing Process an overview ScienceDirect Topics

Wettype mechanochemical polishing or chemical mechanical polishing is a composite polishing activated by the mechanical action of abrasives and the chemical action of a polishing reagent This process is sometimes distinguished from the mechanical and chemical polishing that gains polishing rates similar to the total of mechanical and chemical removal ratesPolishing and buffing are finishing processes for smoothing a workpiece's surface using an abrasive and a work wheel or a leather strop Technically polishing refers to processes that use an abrasive that is glued to the work wheel, while buffing uses a loose abrasive applied to the work wheel Polishing is a more aggressive process while buffing is less harsh, which leads to a smoother, brighter finish A Polishing (metalworking) WikipediaScan line polishing path The scan line path, a conventional machining path, is frequently used in machining In the scan line polishing process, the polishing tool offsets an interval at the boundary and continues the machining until the processing is done Path planning of mechanical polishing process for 01012021 During polishing, the pressurized slurry is transported to the linejet nozzle and impinged out from the line shape orifice to generate a fluid linejet Abrasives in the slurry could be cerium oxide (CeO 2 ), aluminum oxide (Al 2 O 3 ), silicon oxide (SiO 2 ), silicon carbide (SiC), etc, depending on the material of the target surfaces being polishedDevelopment of a fluid linejet polishing process Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment, leaving a clean surface with a significant specular reflection In some materials, polishing is also able to reduce diffuse reflection to minimal values When an unpolished surface is magnified thousands of times, it usually looks like a succession of mountains and valleys Polishing Wikipedia

Mechanical polishing PlasmaCraft

Mechanical polishing Final polishing of part surfaces is carried out mechanically through the use of abrasive wheels and tapes with polishing pastes or through the use of round type vibratory machines Polishing paste application makes it possible to reach roughness value equal to R а =0,05–0,12 micronsElectropolishing is an electrochemical finishing process that removes a thin layer of material from a metal part, typically stainless steel or similar alloys The process leaves a shiny, smooth, ultraclean surface finish Also known as electrochemical polishing, anodic polishing or electrolytic polishing, electropolishing is especially useful for polishing and deburring parts that are fragile What is Electropolishing? How Does Although the process is roughly 65 years old, substantial refinements have taken place Many electrolytes have been developed to allow for electropolishing of a broad range of metals These newer electrolytes, together with advanced parts handling techniques, have combined to improve production yields on a wide range of metal productsElectropolishing Deburring Basics Able Polishing Process The process begins with the use of coarse diamond segments bonded in a metallic matrix These segments are coarse enough to remove minor pits, blemishes, stains, or light coatings from the floor in preparation for final smoothing Depending on the condition of the concrete, this initial rough grinding is generally a three to fourstep processPolished Concrete Process Steps for Polishing Additional SFP560A features include 1) Programmable polishing process up to 60 processes, 2) Four (4) multitimers for manual polishing operation, 3) High Contrast, waterproof LCD Display with multilanguage programming operation (ENGCHNSPNJPN), 4) Selectable, password protected programming and operations modes for both administrators and users 5) Operation and Maintenance Polishing Machine PRODUCTS SEIKOH GIKEN

Mechanical polishing PlasmaCraft

Final polishing of part surfaces is carried out mechanically through the use of abrasive wheels and tapes with polishing pastes or through the use of round type vibratory machines Polishing paste application makes it possible to reach roughness value equal to Rа=0,05–0,12 microns At the same time polishing process usually involves manual labourIn this paper, a fluid linejet polishing (FLJP) process was developed for the polishing of rotational axisymmetric surface (RAS) FLJP aims to enhance the polishing efficiency of Development of a fluid linejet polishing process Chemical Mechanical Polishing During the metal Chemical Mechanical Polishing (CMP), the levels of metals (Cu or W) and oxides are reduced, causing surface irregularities Both line width and pattern density (eg, line density) influence yield and contribute to the surface variation The CMP process must be optimized to achieveChemical Mechanical Polishing (CMP) Metrology with Laser polishing is a technology of smoothening the surface of various materials with highly intense laser beams When these beams impact on the material surface to be polished, the surface starts to be melted due to the high temperature The melted material is then relocated from the ‘peaks to valleys’ under the multidirectional action of surface tension By varying the process Review on mechanism and process of surface Although the process is roughly 65 years old, substantial refinements have taken place Many electrolytes have been developed to allow for electropolishing of a broad range of metals These newer electrolytes, together with advanced parts handling techniques, have combined to improve production yields on a wide range of metal productsElectropolishing Deburring Basics Able

Multi Bowl Automated Process Polishing Line

polishing of stainless steel cookware in high volumes, although the process line can be used with any of the proprietary vibratory finishing processes such as: Deburring, grinding, radiusing, general parts cleaning, descaling, degreasing and polishing of stampings, castings, formed, forged and sawcut parts as well as machined componentsElectropolishing is an electrochemical finishing process that removes a thin layer of material from a metal part, typically stainless steel or similar alloys The process leaves a shiny, smooth, ultraclean surface finish Also known as electrochemical polishing, anodic polishing or electrolytic polishing, electropolishing is especially useful for polishing and deburring parts What is Electropolishing? How Does 01022020 Reapply polishing compound to the wheel as necessary The process of polishing your metal will cause the compound on the buffing wheel to wear off If your metal is still tarnished when this happens, all you have to do is add more compound to the wheel and continue polishing3 Easy Ways to Polish Metal wikiHowProcess conditions for the Capto adhere polishing step run in FT mode (after Capto S ImpAct step run in B/E mode) Process step Buffer CV Residence time (min) Equilibration 25 mM acetate + 25 mM phosphate + 120 mM NaCl, pH 62 or 63* 3 27 chromatographyContinuous chromatography in downstream processing of a Start studying SDI Firearm Finishes and Engraving (FTT 201) Learn vocabulary, terms, and more with flashcards, games, and other study toolsBest SDI Firearm Finishes and Engraving (FTT

AN INTRODUCTION TO BUFFING AND POLISHING

Buffing and polishing using wheels and The division of these two areas is marked with the dotted line on the above drawings The workpiece must only be applied to the area of the buff that is rotating AWAY from the workpiece You should ensure that you are completely aware which area is which, Although the process is roughly 65 years old, substantial refinements have taken place Many electrolytes have been developed to allow for electropolishing of a broad range of metals These newer electrolytes, together with advanced parts handling techniques, have combined to improve production yields on a wide range of metal productsElectropolishing Deburring Basics Able This means the surfaces are completely devoid of lines, grooves, pits, or divots The polished surfaces also withstand corrosion from food handling and sanitising chemicals Polishing is ideal for a number of applications including steel fabrication, steel sheet assembly, kitchen equipment fabrication, and in many other scenarios which demand powerful, versatile and reliable polished finishesStainless Steel Sheet Coil Polishing Midway Polishing Process The process begins with the use of coarse diamond segments bonded in a metallic matrix These segments are coarse enough to remove minor pits, blemishes, stains, or light coatings from the floor in preparation for final smoothing Depending on the condition of the concrete, this initial rough grinding is generally a three to fourstep processPolished Concrete Process Steps for Polishing 12062009 Mirror polishing is achieved by starting with a course polishing media, then using a finer one to remove the polishing lines, with the process continuing for 4 or more steps, ending with a very fine buffing compound The wheels are changed too; fine media isn't put on a Polishing stainless steel Problems Solutions

Wave line(marks) on mold polishing process

23032019 1.Inappropriate Operation Firstly , during the polishing process, the operator may have applied inappropriate polishing method / technique or ununiform force, or the polisher rotates too fast during the process, causing the mold surface to heat up, which gives the mold an even surface after polishing, ie, the appearance of flow linesFRENCH POLISHING French Polishing is the name given to the process of coating wood with a solution of shellac dissolved in alcohol, using a “rubber” made of rag and cotton wool instead of with a brush The alcohol evaporates, leaving the shellac deposited upon the wood When applied correctly it produces what is possibly the finest looking Guide to French Polishing Wood Finish SupplyThe optimal control parameters for the polishing of the glass substrate of supertwisted nematicliquid crystal display (STNLCD) were explored The Taguchi technique was used to formulate the experimental layout The surface characteristics caused by the polishing process were analyzed with atomic force microscopy (AFM)Optimization of the Polishing Parameters for The polishing process starts with filtration This is done by passing tertiary wastewater over filters (which can be bed of sand or charcoal) This causes the particulate matter from water to attach to the filter media thus making the water free of such most of such matter The next step in polishing treatment process is called lagooningWastewater Polishing treatment process CAAdditional SFP560A features include 1) Programmable polishing process up to 60 processes, 2) Four (4) multitimers for manual polishing operation, 3) High Contrast, waterproof LCD Display with multilanguage programming operation (ENGCHNSPNJPN), 4) Selectable, password protected programming and operations modes for both administrators and users 5) Operation and Maintenance Polishing Machine PRODUCTS SEIKOH GIKEN