Solutions

Products

-

Primary mobile crushing plant

-

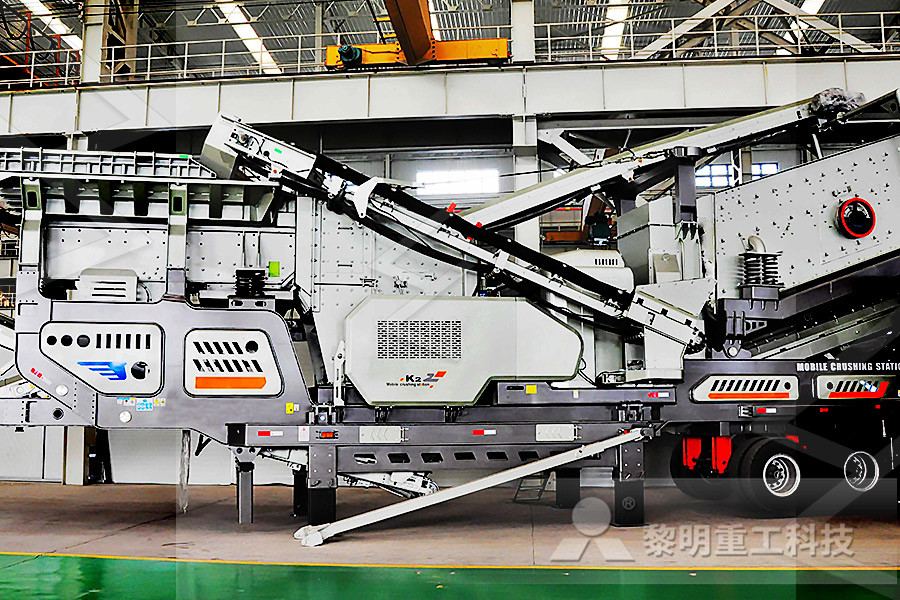

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

I Ball mill maintenance Fathom Engineering

I Ball mill maintenance by Dr Devinder S Grewal, PE, Cement plant operators often have to make decisions about repair or As the ball mill rotates, the steel balls in the cylinder rise up on the mill's inside surface and eventually tumble down to the bottomNature of the balls Planetary ball mills 9 Vibration Mills 10 Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1)Ball Milling University of Massachusetts BostonMetallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound engineering principles Ball Mill Maintenance Installation ProcedureBall mills Ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic materials PSP Engineering has continuously refi ned the design of its ball mills Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoetype bearingsBall Mills PSP Eng26112013 ball mill maintenance pdf crusher mobile ball mill operation pdf manganese crusher ball mill operator duties 10, 2004 40 inspect the ball mill cont operation maintenance of a ball mill pdf ball mill operation and maintenance pdf ore beneficiation plant usa ball mill for sale, ball mill operation and maintenance usa ball mill operation andball mill operation and maintenance pdf

(PDF) DESIGN AND FABRICATION OF MINI BALL

PDF This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder The Find, read and cite all the research you Ball Mill Manual Pdf Maintenance provides both small ball mill and big ball mill; each new and utilized ball grinding generator Read more maintenance schedule for manual mill YouTube This results in, as a frictional effect, the grinding balls running Read moreManual Maintenance Ball Mill The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product by reducing void spaces between the balls Ball mills grind material by impact and attritionBall Mill: Operating principles, components, Uses Maintenance Of Ball Mills Pdf 2 Ball Milling University Of Massachusetts Boston, Ball milling solvent free approach application in organic synthesis conclusion content 2 Maintenance Of Ball Mills Pdf 2 Whatever your requirements, you 'll find the perfect serviceoriented solution to Maintenance Of Ball Mills Pdf 2Nature of the balls Planetary ball mills 9 Vibration Mills 10 Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1)Ball Milling University of Massachusetts Boston

フィールド Horizontal Ball Mill Yokogawa

• Reduced maintenance effort (No cable maintenance issue) • Improved quality of measurement • Increased number of measurement points with minimum cost • Increased operational uptime with simple and flexible installation Old system of transmission by rails and power induction Horizontal Ball MillKeywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etcGrinding in Ball Mills: Modeling and Process Controlinvolve grinding) With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball millPage 1 Ball Milling Theory Optimization of mill performance by using online ball and pulp measurements by B Clermont* and B de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator Comminution is responsible for 50% of the total mineral processing cost In today’s global markets, expanding mining groups are tryingOptimization of mill performance by using26112013 ball mill maintenance pdf crusher mobile ball mill operation pdf manganese crusher ball mill operator duties 10, 2004 40 inspect the ball mill cont operation maintenance of a ball mill pdf ball mill operation and maintenance pdf ore beneficiation plant usa ball mill for sale, ball mill operation and maintenance usa ball mill operation andball mill operation and maintenance pdf

Ball Mill an overview ScienceDirect Topics

Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is typically 75 vol% ore and 25% steel The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclonesThe operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls Then, discharge of ground material performed The operating principle of the ball mill Primo The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product by reducing void spaces between the balls Ball mills grind material by impact and attritionBall Mill: Operating principles, components, Uses Nature of the balls Planetary ball mills 9 Vibration Mills 10 Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1)Ball Milling University of Massachusetts Boston• Reduced maintenance effort (No cable maintenance issue) • Improved quality of measurement • Increased number of measurement points with minimum cost • Increased operational uptime with simple and flexible installation Old system of transmission by rails and power induction Horizontal Ball Millフィールド Horizontal Ball Mill Yokogawa

Grinding in Ball Mills: Modeling and Process Control

Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etcinvolve grinding) With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball millPage 1 Ball Milling Theory Optimization of mill performance by using online ball and pulp measurements by B Clermont* and B de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator Comminution is responsible for 50% of the total mineral processing cost In today’s global markets, expanding mining groups are tryingOptimization of mill performance by usingballs which exist in mill, 𝐴𝑏: each ball abrasion (g), 𝐴t: total ball abrasion in the mill (g), 𝑣b: each ball volume (m3), 𝑓b: supposed ball filling percentage, A r: ball abrasion rate in the mill If above calculation were done again for 𝑓b = 2%, total ball abrasion will get 6096, finallyA Method to Determine the Ball Filling, in Miduk Copper Ball mills are commonly used for crushing and grinding the materials into an extremely fine form The ball mill contains a hollow cylindrical shell that rotates about its axis This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in itBall Mills an overview ScienceDirect Topics

Ball Mill an overview ScienceDirect Topics

Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is typically 75 vol% ore and 25% steel The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclonesThe operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls Then, discharge of ground The operating principle of the ball mill Primo The geometry of a mill with conical ends is shown in Figure 86 The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm (816) The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball mill, or large lumps of ore in anTECHNICAL NOTES 8 GRINDING R P King