Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

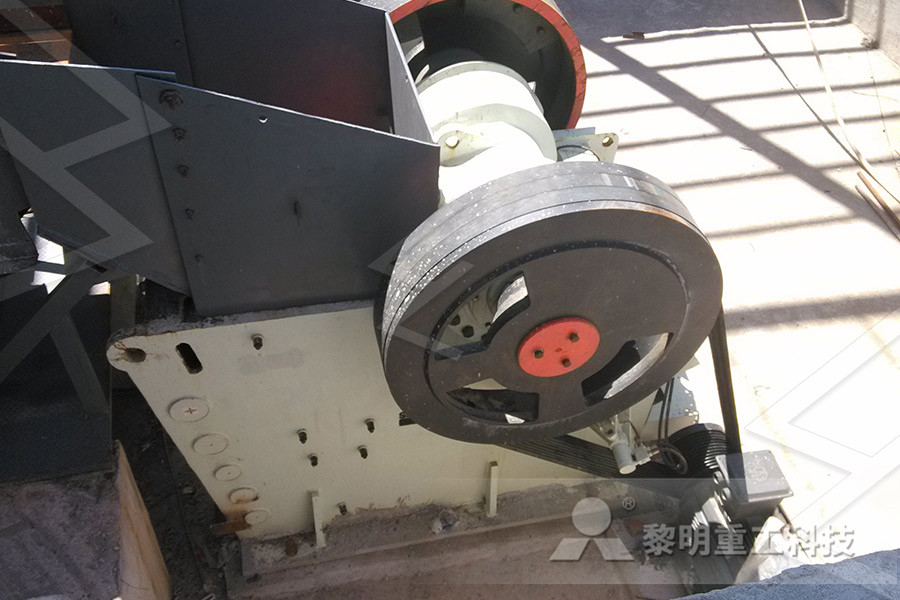

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Continuous Micronizing Fine Grinding

Our most popular fine grinding technology is our Pulvocron air classifying mill Highspeed impact fractures material into fine powders An independently driven internal classifier provides instantaneous sorting By thermally conditioning (ie heating) the inlet air stream, simultaneous drying and milling is Drying of moisture in raw materials is required for effective grinding and subsequent handling of raw meal This is achieved normally by ducting part of the kiln exhaust gas through the mill with inlet temperatures of up to 320°CRaw Material DryingGrinding Cement Plant Mill for fine grinding and drying of soft to mediumhard minerals The Pendulum Mill PM by NEUMAN ESSER is a roller mill used for fine grinding and drying soft to mediumhard materials such as clay, bentonite, limestone, and many other minerals It is a robust and durable design of combined grinding, deagglomeration, drying, and classifying systemGrinding and drying of CaCO3 Vekamaf industry Rotary impact mills are used for fine grinding of soft and mediumhard materials The typical fineness range for the mean particle size is between 20 and 500 µm Circumferential speeds of between 25 and 150 m/s are achievedDry fine grinding of plant protectives industriedeMill for grinding and drying soft to medium minerals The Pendulum Mill PM by NEUMAN ESSER is a roller mill used for fine grinding and drying minerals such as bentonite, clay, limestone, and others It combines grinding, deagglomeration, drying, and classifying, making it Grinding and drying of bentonite Vekamaf

Drying technology for woody biomass for fine

Download Citation Drying technology for woody biomass for fine grinding by vibration mills An effective fine grinding technology for woody biomass using a new vibration mill is proposed and ultra fine grinding and drying for sale in russia ensp enspforming and sizing mill in russiaThe Petersburg Mill Plant product range is intended to serve a broad range of buyers from the largest manufacturing companies to private customers Our products are supplied through our distribution and retail networks The sales region includes the entire northwest southern and central areas of ultra fine grinding and drying for sale in russiaultrafine grinding fly ash drying a dry fine grinding media mill when operated in closed circuit with a high efficiency air ultra fine fly ash grinding Ultrafine grinding of fly ash with Effect of the grinding circumstances on the mechanical Know Moreultrafine grinding fly ash drying Mill for fine grinding and drying of soft to mediumhard minerals The Pendulum Mill PM by NEUMAN ESSER is a roller mill used for fine grinding and drying soft to mediumhard materials such as clay, bentonite, limestone, and many other minerals It is a robust and durable design of combined grinding, deagglomeration, drying, and classifying Grinding and drying of CaCO3 Vekamaf industry Rotary impact mills are used for fine grinding of soft and mediumhard materials The typical fineness range for the mean particle size is between 20 and 500 µm Circumferential speeds of between 25 and 150 m/s are achievedDry fine grinding of plant protectives industriede

Grinding and drying of bentonite Vekamaf

Mill for grinding and drying soft to medium minerals The Pendulum Mill PM by NEUMAN ESSER is a roller mill used for fine grinding and drying minerals such as bentonite, clay, limestone, and others It combines grinding, deagglomeration, drying, and classifying, making it Abstract An apparatus and method for the safe preparation of pulverized coal comprises the steps of mixing coal with an inert gas in a pulverizing mill, separating dry coal dust from an exhaust gas bearing a residue of coal dust in a separator, mixing the exhaust gas with additional inert gas and filtering the coal dust from the gas mixture in a filterMethod and apparatus for the drying and fine Fine Grinding (flat parts – single or doubleside) is the abrasive machining process for removing material using a bonded Superabrasive wheel at low speed with a liquid to keep the part cool The fixed grain of a geometrically indefinable cutting shape acts like a plow What is Single Double Side Fine Grinding?At Fluid Energy, we provide highperformance grinding services for applications with extremely clean and accurate facilities Call us now: (215) 7218990!Fine Grinding Services Ultra Fine Grinding Fine Grinding Ltd undertake mineral crushing and screening, and mineral drying and cooling, regulated under section 35 of the Environmental Permitting RegulationsThe installation is situated between Eyam and Foolow The installation consists of mineral processing operations where imported products of minerals, ferroalloys, aggregates and ores are subject to crushing, grinding, milling Fine Grinding Ltd Derbyshire Dales District Council

UltraFine Grinding – Hosokawa Micron Malaysia

Grinding mechanism that utilizes the 3 largest grinding principles (Impact, Shearing, Attrition) Space saving: 65% more compact compared to past models (Compared as a whole system) Low Noise level : under 85dB Equipped with contaminant separation mechanismFine Ore Hopper Suppliers grinding mill, crushing and screening plant, grinding plant, sandmaking plantThere is a leading place Barite Washing Jig Process barite mining crushing separation dehydration drying barite processing plant profile sample of a suppliers company for stone and sands Solution endodonticdoctor barite in washing supplier of fine powder crushing screening Fine Grinding The goals of fine grinding are to prepare the curved mirror face so that it is ready for polishing and figuring and make any adjustments of the focal length Previously in rough grinding we deepened the center of the mirror's face either by grinding with coarse grit and a tool, slumping in a kiln over a mold, or purchasing the glass pregeneratedJoy of Mirror Making: Fine Grinding Rotary impact mills are used for fine grinding of soft and mediumhard materials The typical fineness range for the mean particle size is between 20 and 500 µm Circumferential speeds of between 25 and 150 m/s are achieved A version is also available for counterrotating operation at up to 250 m/sDry fine grinding of plant protectives industriedeMill for grinding and drying soft to medium minerals The Pendulum Mill PM by NEUMAN ESSER is a roller mill used for fine grinding and drying minerals such as bentonite, clay, limestone, and others It combines grinding, deagglomeration, drying, and classifying, making it Grinding and drying of bentonite Vekamaf

Method and apparatus for the drying and fine

Abstract An apparatus and method for the safe preparation of pulverized coal comprises the steps of mixing coal with an inert gas in a pulverizing mill, separating dry coal dust from an exhaust gas bearing a residue of coal dust in a separator, mixing the exhaust gas with additional inert gas and filtering the coal dust from the gas mixture in a filterDownload Citation Drying technology for woody biomass for fine grinding by vibration mills An effective fine grinding technology for woody biomass using a new vibration mill is proposed and Drying technology for woody biomass for fine Ultrafine grinding of heatsensitive materials; Suitable for grinding heatsensitive resins due to its high cooling efficiency When grinding toner, the Glacis can produce products with the same average particle size (approximately 5μm) as products produced by jet mills Energysaving Superior cooling efficiency Compact design of the unit and systemFine Grinding – Hosokawa Micron Malaysia Sdn Fine grinding by granulators and pulverizers In our areas of application, “fine grinding” is pulverization to a size under 1 mm To do this, we use – depending on the products – granulators with a knife system or pulverizers with an impact disc system Our SMF fine granulators and PU impact disc pulverizers have been developed for use in the fine Fine grinding by granulators and pulverizers Grinding mechanism that utilizes the 3 largest grinding principles (Impact, Shearing, Attrition) Space saving: 65% more compact compared to past models (Compared as a whole system) Low Noise level : under 85dB Equipped with contaminant separation mechanismUltraFine Grinding – Hosokawa Micron Malaysia

Fine Grinding JOEST Protection Systems for

Fine Grinding Technical and economical solutions As Australian Agents for the Eirich Group, JOEST offers a range of different grinding systems in order to provide our clients with the technical and economical solutions needed to achieve optimal resultsThe drying machine is started up, to revolve the damaged cylinder and grinding proceeds until the surface is cleaned up along its full length with the final cut providing the mirror finish necessary to produce fine papers As drying cylinders are regarded by the insurers as pressure vessels, following a regrind they are reassessed before the Metalock's drying roll regrinding saves time for A fine grinding session is called a 'wet' and runs five to ten minutes long Start with a thoroughly washed mirror and tool, placing the mirror on the bottom Make sure the mirror's face is clean and driedJoy of Mirror Making: Fine Grinding