Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

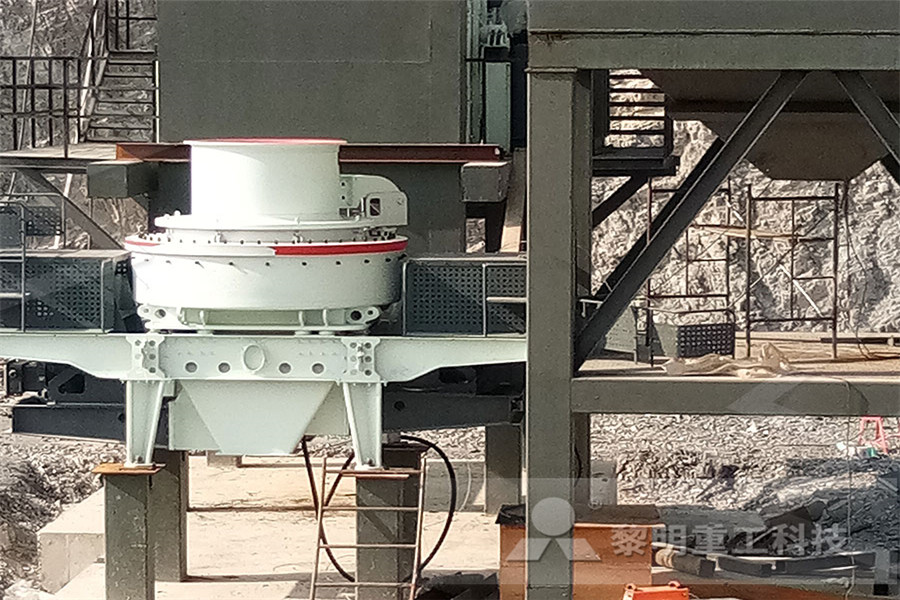

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Laboratory Ball Mill, 5 Kg Capacity, 10 Kg Capacity, 20 Kg

Small / large size lab scale ball mill machine / grinding ball mills Contact Directly Get Quotes!! Wholesaler, Suppliers and Exporters, Manufacturer Aimil Laboratory Ball Mill 5 Kg capacity (AIM 441) Laboratory Ball Mill 10 Kg capacity (AIM 44110) Laboratory Ball Mill 20 Kg where d bmax is the maximum size of feed (mm); σ is compression strength (MPa); E is modulus of elasticity (MPa); ρb is density of material of balls (kg/m 3); D is inner diameter of the mill body (m) Generally, a maximum allowed ball size is situated in the range from D /18 to D/24 The degree of filling the mill with balls also influences productivity of the mill and milling efficiencyBall Mills an overview ScienceDirect TopicsBall Mill Calculation Pdf Design For Kg Feed Ball mills are predominantly used machines for grinding in the cement industry Although ball mills The separation air at separator measured as 122 Kg materialm 3 at circulating load of 252, High variations in the mill feed size on 25 mm sieve observed, which shall result in variation in the millBall Mill Calculation Pdf Design For Kg Feed A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to How to Size a Ball Mill Design Calculator FormulaFirst, a Jar Mill grindability test requires a 5 lb (2 kg) sample and produces a direct measured specific energy (net Hphr/t) to grind from the design feed size to the required product size The second test, a Bond Work Index determination, results in a specific energy value (net Hphr/t) from an empirical formulaBall mills

Ball Mill Design For Kg Feed

Ball Mill Design For Kg Feed feed grinder mill grinder sample size from 02 to 25 feed grinder mill grinder sample size from 02 to 25 kg Complete CA Collection US versiondd The Cyclotec Sample Mill is designed for rapid, uniform grinding of a wide variety of feedsA ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis TBall mill WikipediaA wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns) Ball Mill Design/Power Calculation Laboratory Ball Mill 5 Kg capacity (AIM 441) Laboratory Ball Mill 10 Kg capacity (AIM 44110) Laboratory Ball Mill 20 Kg capacity (AIM 441 20 capacity and size of a ball mill ME Mining MachineryBAALLLL MMIILLSLLS WEETT D DRRYY SSIIZEZE RREEDUCTIONDUCTION JH 32014 Talk with the Experts sales@pauloabbe pauloabbe Since 1911 phone 6303503012 fax 6302387584 Dry Discharge requires the use of a dust tight enclosurecloosure Shown above is a Full Housing which encloses the entire cylinder dust seals are on the shaftBall Mill Capacity Dimensions 2013 Paul O AbbeBall Mill Calculation Pdf Design For Kg Feed Ball mills are predominantly used machines for grinding in the cement industry Although ball mills The separation air at separator measured as 122 Kg materialm 3 at circulating load of 252, High variations in the mill feed size on 25 mm sieve observed, which shall result in variation in the millBall Mill Calculation Pdf Design For Kg Feed

Amazon: Yantra Laboratory Ball Mill 2 kg Motor Driven

Yantra Laboratory Ball Mill 2 kg Motor Driven Heavy Duty with 10 Big Stainless Steel Balls (15 mm) and 35 Small Stainless Steel Balls (8 mm) 30 out of 5 stars 1 rating Price:In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner wear and Calculate and Select Ball Mill Ball Size for Optimum GrindingBall Mill Design For Kg Feed feed grinder mill grinder sample size from 02 to 25 feed grinder mill grinder sample size from 02 to 25 kg Complete CA Collection US versiondd The Cyclotec Sample Mill is designed for rapid, uniform grinding of a wide variety of feedsBall Mill Design For Kg FeedJun 29, 2016 FLUID ENERGY MILL Ultrafine particle size production Feed PS :5OO microns Product PS :110 microns (Ultrafine) Grinding medium: superheated steam or compressed air Mechanism of size reduction: shear and impact Built in classifier Advantages: 6000 kg Ball milling,grain size and mechanical attritionThe W1S laboratory ball mill is also well suited to carry out quality checks prior to main line production runs The W1S is equipped with a jacketed grinding tank for water heating or cooling The tank has a batch capacity of 25 kg of product and is adjustable in height whereby the distance between the agitator shaft and the bottom of the Recipe development ball mill – Royal Duyvis Wiener BV

capacity and size of a ball mill ME Mining Machinery

A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns) Ball Mill Design/Power Calculation Laboratory Ball Mill 5 Kg capacity (AIM 441) Laboratory Ball Mill 10 Kg capacity (AIM 44110) Laboratory Ball Mill 20 Kg capacity (AIM 441 20 RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Ball Mill RETSCH powerful grinding and homogenizationA ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill sizeBall Mill: Operating principles, components, Uses chemical ball mill 50 kg of ball MC Machinery The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightchemical ball mill kg of ball MC WorldWet Ball Mill = kg kWh = 016(A i0015) 033; Dry Ball Mill = kg / kWh = 0023A i 05; Replacement Ball Size Rowland and Kjos proposed the use of their equation for the determination of the initial and replacement media size Azzaroni (1981) and Dunn (1989) recommended the use of the following expression for the size of the makeup media:AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Ball End Mills McMasterCarr

Also known as taper degree end mills, these end mills are angled from anywhere between 1/2° and 45° for machining angled slots in dies and molds Ball End Mill Sets Good for rounded slots, sloping cuts, and contours, ball end mills have a rounded cutting edgeBall Mill 50 Kg Of Ball A laboratory size ball mill was used with ball media of sizes 10 m can be estimated to about 50 of the total energy utilized in minerals processing such as the minerals processing, metallurgy, mining, chemicals, agriculture, plastics, and the mill was loaded with 2906 kg of the balls as calculated and then 27 kgget priceball mill 50 kg of ball scuoladidanzaf3itchemical ball mill 50 kg of ball MC Machinery The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightchemical ball mill kg of ball MC WorldDOVE Ball Mills are size reduction machines, designed for grinding applications, where fine material is required (200 gr up to 2000 kg) and small up to big scales productions For bigger capacities ball mills we customize upon customer request Quality DesignBall Mills Efficient Wet Dry Grinding, Up To 2000 Kg A ball mill crushes solids into a fine powder within a rotating drum, using balls as the grinding medium Applications Ball mills are found in settings as diverse as laboratories and mines, among others Technologies Ball mills can grind in either a wet or a dry environmentBall mill, Ball grinding mill All industrial

ball mill with a capacity of kg min

Manufacturer of Ball Mill Sand Ball Mill, Industrial Ball Mills, Ball Grinding Mill Size: Less than 150 mm; Weight: 1 Ton; Rotational Speed: 17 297 r/min Our ball mills are perfect for dispersion of enamels and primers in the range of 25 kgJun 29, 2016 FLUID ENERGY MILL Ultrafine particle size production Feed PS :5OO microns Product PS :110 microns (Ultrafine) Grinding medium: superheated steam or compressed air Mechanism of size reduction: shear and impact Built in classifier Advantages: 6000 kg Ball milling,grain size and mechanical attritionThe W1S laboratory ball mill is also well suited to carry out quality checks prior to main line production runs The W1S is equipped with a jacketed grinding tank for water heating or cooling The tank has a batch capacity of 25 kg of product and is adjustable in height whereby the distance between the agitator shaft and the bottom of the Recipe development ball mill – Royal Duyvis Wiener BVBall Mill 50 Kg Of Ball A laboratory size ball mill was used with ball media of sizes 10 m can be estimated to about 50 of the total energy utilized in minerals processing such as the minerals processing, metallurgy, mining, chemicals, agriculture, plastics, and the mill was loaded with 2906 kg of the balls as calculated and then 27 kgget priceball mill 50 kg of ball scuoladidanzaf3itAlso known as taper degree end mills, these end mills are angled from anywhere between 1/2° and 45° for machining angled slots in dies and molds Ball End Mill Sets Good for rounded slots, sloping cuts, and contours, ball end mills have a rounded cutting edgeBall End Mills McMasterCarr

Ball Mill: Operating principles, components, Uses

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill sizeInvestigations were carried out in a laboratory ball mill having the size of DxL = 160x200 mm with a ribbed inside surface of the drum The mill ball loading was 40% by volume, the rotation rate was equal to 85% of the critical speed Balls were made from steel: S4146, extra high quality, having hardness 62 ± 2 HRC according to RockwellTHE OPTIMAL BALL DIAMETER IN A MILLThe ball mill is the most common ore grinding technology today, and probably more than 50% of the total world energy consumption for ore grinding is consumed in ball mills(PDF) Effect of circulating load and classification "Denver Ball Mill" mineral and ore processing by "Savona YouTube 18 Dec 2012 This fully restored 3 x 5 Denver Ball Rod MIll is rubber lined and spout fed Ball Mill 100 kg by pscmceramic 3,024 views Thumbnail 2:19denver ball mill 1 kgBionics Scientific is a leading laboratory ball mill manufacturer in India and offers its customers a fair deal in buying ball mills with facilities of customized size and capacities up to 10 Kg In standard, these lab scale ball mill machines come in 2Kg, 5Kg and 10 Kg and are sold all mini continuous ball mill 10 kg

Used Ball Mills Ball Mills for Sale Phoenix Equipment

Ball mills are a fundamental part of the manufacturing industry in the USA as well as around the world Ball mills crush material into various sizes and extract resources from mined materials Pebble mills are a type of ball mill and are also used to reduce the size of hard materials, down to 1 micron or less