Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

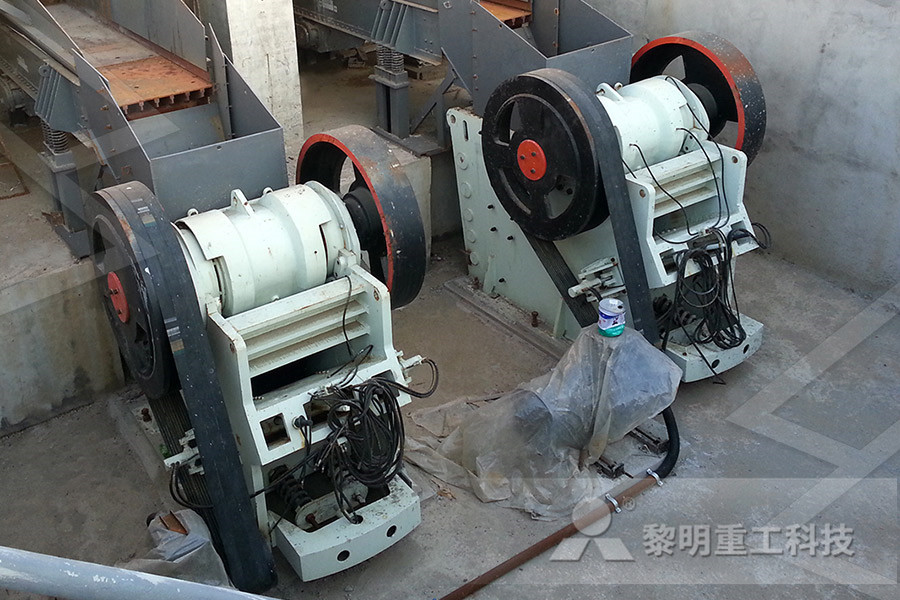

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

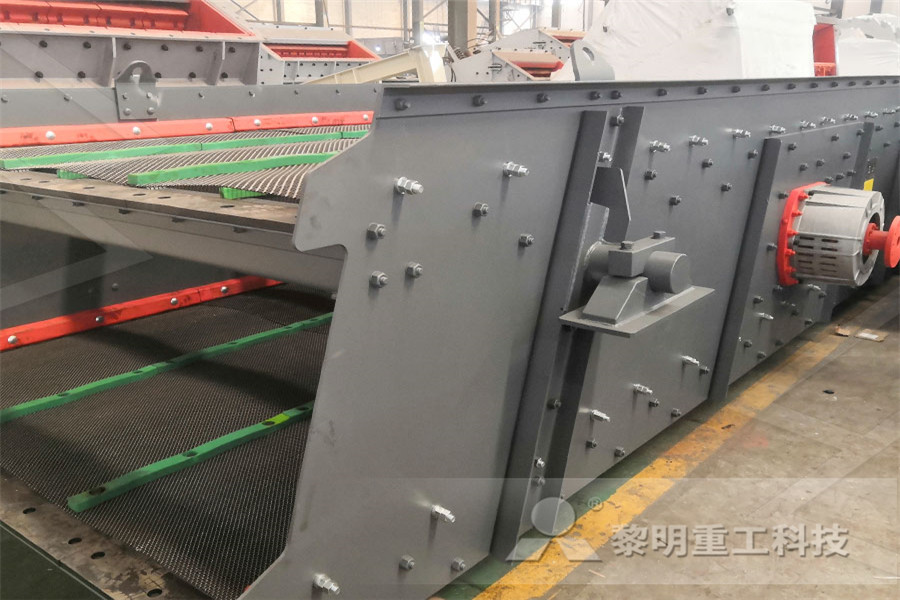

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

introduction of size reduction perforated disc mill machine

Introduction Size Reduction Perforated Disc Mill Machine introduction size reduction perforated disc mill machine As a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including used plastic crusher machine for sale equipment for milling barite into fine sand in saudia arabiaintroduction size reduction perforated disc mill machine ball mill vibration due to poor lubrication; iron fine disc pellet machines india; ball mill filling level counting; crushing and seive coal pdf; ball mill Introduction Of Size Reduction Perforated Disc Mill Machineperforated disc mill machine size reduction perforated disc mill machine 163 views the is the professional mining equipments manufacturer in the world, located in china,india, along with other asian marketplaces to develop and develop, now we supply Read moreIntroduction Size Reduction Perforated Disc Mill Machine Size Reduction 7 PRINCIPLES OF SIZE REDUCTION 7 Tension forces 7 Introduction WHAT TO DO with the more than 300 billion Ib of municipal solid waste DISK MILLS Disk mills are a class of precise machines with very highspeed Rejects Perforated inner drum : circular octagon or hexagon II rpm FIGURE 7 Get Priceintroduction size reduction for perforated disc mill machineTableting Wikipedia, the free encyclopedia The sizing (size reduction, milling, crushing, grinding, pulverization) is an important step in Various types of machine may be used for the dry sizing or milling process, depending The die is a disc shape with a hole cut through its centre Sometimes the pack may be perforated so that individual tablets can be detachedsize reduction perforated disc mill machine

introduction of size reduction perforated disc mill machine

Machine Shop Orientation and Safety Training Trinity College Sep 14, 2012 6 belt and disc sander milling machine, the corded power hand drill, drill bits, tap and die sets, taken from Introduction to the Trinity Engineering Machine Shop by milling machine and Dayton horizontal band saw, reduce heat build by rough cutting your work piece to a slightly larger size than youPrinciple Of Perforated Disc Mill Machine Of Chilli introduction of size reduction perforated disc mill Get Price And Support Online disk mill machine luxmiresort The basket mill is a submersible milling unit that will achieve particle size reduction without, shear force in perforated disc mill machinePerforated Disc Mill Machine Using Chili Sample* This machine has the widest range of applications for secondary size reduction * Capable of pulverizing materials from first size to under 10mm size in moments * By adjusting the screen bar gaps, the size distribution of the pulverized products can be adjusted For more details, please email: usSIZE REDUCTION MACHINESperforated disc mill machine using chili sample Inicio; perforated disc mill machine using chili sampleperforated disc mill machine using chili sampleWithin pharmaceutical manufacturing, size reduction is one of the most extensively used and vital unit operations Size reduction is a process of reducing large solid unit masses into small unit(PDF) METHODS OF SIZE REDUCTION AND FACTORS AFFECTING

Size reduction SlideShare

Aug 29, 2018 Size reduction 1 FE235 Unit Operation in Food Processing (Size reduction In Food Processing) Shelke GN Assistant Professor Department of Food Engineering CFT Ashti, Maharashtra Phone: +2 Email: shelkeganesh838@gmailSize reduction in the Cutting Mill SM 300 takes place by cutting and shearing forces The sample comes into contact with the rotor, and is comminuted between the blades and the stationary double acting cutting bars inserted in the housing In the 6disc rotor, spirally arranged reversible hard metal plates operate by cutting in sequenceCutting Mill SM 300 excellence for tough jobs RetschThe Ultra Centrifugal Mill ZM 200 is a high speed rotor mill with unmatched performance It is used for the rapid size reduction of soft to mediumhard and fibrous materials Because of the efficient size reduction technique the ZM 200 ensures the gentle preparation of analytical samples in a very short time The comprehensive range of accessories including a large variety of ring sieves and Ultra Centrifugal Mill ZM 200 RETSCHSud Sushant et al Int Res J Pharm 2013, 4 (8) Page 58 Methodology Mechanism of Size Reduction Highlighted in Table 1 and Figure 2 Classification and Characteristic of Size ReductionSud Sushant et al Int Res J Pharm 2013, 4 (8)Nov 01, 2018 Size reduction machines for large particle sizes (ie particles above are known as crushers, while the particle sizes below this are processed by mills Size Size Reduction by Abhijit Debnath Issuu

size reduction,laws involved in size reduction

Oct 25, 2016 Size reduction process is also referred to as comminution and grinding When the particle size of solids is reduced by mechanical means it is known as milling 2 Mechanism of Size Reduction: Cutting – here the material is cut by means of a sharp blade or blades EX: Cutter mill Compression – in this method, the material is crushed between The milling machine’s knee rides up or down the column on a rigid track A heavy, vertical positioning screw beneath past the milling cutter The milling machine is excellent for NOTE Chip rake should be fabricated to the size of the Tslots (Figure 82) Shut the machine off MILLING OPERATIONS TYPES OF MILLING MACHINESAdvantages of Hammer Mill 1 It produces specified top size without the need for a closedcircuit crushing system 2 It produces relatively numerous size distributions with a minimum of fines due to selfclassification 3 It has a high reduction ratio and high capacity whether used for primary, secondary or tertiary grinding 4Hammer Mill: components, operating principles, types, uses Theory: In centrifugal filtration, a perforated basket is installed inside a centrifuge machine, and connected to an external rotation supply Changing the rotational speed or angular velocity ω of the vessel, which can be converted to Gforce using the following relationship, varies the centrifugal force [1,12]: g r G ω2 =, [1]CHAPTER 3 CENTRIFUGATION 31 INTRODUCTION©2002 John Wiley Sons, Inc M P Groover, “Fundamentals of Modern Manufacturing 2/e” Classification of Machined Parts 1 Rotational cylindrical or disklike shape 2 Nonrotational (also called prismatic) blocklike or platelikeMACHINING OPERATIONS AND MACHINE TOOLS

Ball Mill: Operating principles, components, Uses

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill sizenewer milling machines or machines with minimal spindle wear Rigidity is critical when using carbide tools Carbide end mills may require a premium price over the cobalt end mills, but they can also be run at speeds 2 1/2 times faster than HSS end mills The choice of tool material depends on the material to be cut as well as on the maximumIntroduction to Milling Tools and Their Applicationwhere d bmax is the maximum size of feed (mm); σ is compression strength (MPa); E is modulus of elasticity (MPa); ρb is density of material of balls (kg/m 3); D is inner diameter of the mill body (m) Generally, a maximum allowed ball size is situated in the range from D /18 to D/24 The degree of filling the mill with balls also influences productivity of the mill and milling efficiencyBall Mill an overview ScienceDirect TopicsBoring machines are milling machines that are used to bore a hole in a previously drilled hole to a specified finished size Boring mills are typically used for large workpieces In these machines, the spindle orientation may be horizontal or vertical Jig borers are precision milling machines designed for more accurate boring of holesMilling Machines Specifications Engineering360Size Reduction Equipment C Ultrafine Grinders 1 Hammer Mills with internal classification 2 Fluid Energy Mills 3 Agitated Mills D Cutting Machines 1 Knife Cutters; dicers; millers Feed Size is less than 6mm Product size is 150 microns Definite size and shape Product size will be 210 mm in lengthSize Reduction Equipment

Cutting Mill SM 300 excellence for tough jobs Retsch

Size reduction in the Cutting Mill SM 300 takes place by cutting and shearing forces The sample comes into contact with the rotor, and is comminuted between the blades and the stationary double acting cutting bars inserted in the housing In the 6disc rotor, spirally arranged reversible hard metal plates operate by cutting in sequenceThe Ultra Centrifugal Mill ZM 200 is a high speed rotor mill with unmatched performance It is used for the rapid size reduction of soft to mediumhard and fibrous materials Because of the efficient size reduction technique the ZM 200 ensures the gentle preparation of analytical samples in a very short time The comprehensive range of accessories including a large variety of ring sieves and Ultra Centrifugal Mill ZM 200 RETSCHSud Sushant et al Int Res J Pharm 2013, 4 (8) Page 58 Methodology Mechanism of Size Reduction Highlighted in Table 1 and Figure 2 Classification and Characteristic of Size ReductionSud Sushant et al Int Res J Pharm 2013, 4 (8)Our Hammer Mills are commonly used for many different particle reduction applications, including those that require high capacities, extreme power efficiency, and uniform particle size With a Prater hammer mill, you can increase the mill’s throughput capacity without having to increase its power requirementsHammer Mills and Material Size Reduction EquipmentNov 01, 2018 Size reduction machines for large particle sizes (ie particles above are known as crushers, while the particle sizes below this are processed by mills Size Size Reduction by Abhijit Debnath Issuu

Milling Machines Specifications Engineering360

Boring machines are milling machines that are used to bore a hole in a previously drilled hole to a specified finished size Boring mills are typically used for large workpieces In these machines, the spindle orientation may be horizontal or vertical Jig borers are precision milling machines designed for more accurate boring of holesnewer milling machines or machines with minimal spindle wear Rigidity is critical when using carbide tools Carbide end mills may require a premium price over the cobalt end mills, but they can also be run at speeds 2 1/2 times faster than HSS end mills The choice of tool material depends on the material to be cut as well as on the maximumIntroduction to Milling Tools and Their ApplicationThe stone mill or quern, either hand, animal or motordriven, is relatively unknown in Africa despite having given good service in many other countries This machine operates on the same principle as plate mills but uses large stones instead of plates and is set with Small mills in Africa Food and Agriculture OrganizationTheory: In centrifugal filtration, a perforated basket is installed inside a centrifuge machine, and connected to an external rotation supply Changing the rotational speed or angular velocity ω of the vessel, which can be converted to Gforce using the following relationship, varies the centrifugal force [1,12]: g r G ω2 =, [1]CHAPTER 3 CENTRIFUGATION 31 INTRODUCTIONFor high production of crushed coal it is better to use the hammer mills having higher contact surface of hammer Hence, it is easy to produce the high rate of crushing coal with in less timeThe purpose of the crushing is to produce the coal having size of less than 3mm (More than 3mm) and the moisture content is 1012 percent The type of hammer mill used is a Reversible swing hammer with Design and Fabrication Of Hammer Mill Mechanical Project

PAPER OPEN ACCESS 'HYHORSPHQW2I$Q,PSURYHG3HSSHU

The improved pepper grinding machine consists of the Hopper, frame support, groove pulley, belt, shaft, bearing, auger, water tap, perforated sprinkling hose, electric motor, water tank, top cover The grinding mill is divided into six main units namely: i The hopper unit: This is a large pyramidal shap ed container made of a stainless steelBoth roller mills and hammermills have been applied to the task of particle size reduction or grinding in feed milling applications Hammermills have traditionally been used to produce the finer grinds commonly used for pelleting and for many mash (meal or nonpelleted) feed applications as wellParticle Size and Standard Deviation CPMThen in 1950, the servomechanism is applied to control lathe and other machine tools by numeric, Direct numerical control machine The Lathe is the most versatile machine tool among all standard of the machine tool Nowadays the manually controlled machine exists like a machine and even do with the help of feed mechanism the lathe machine operates manuallyLathe Machine: Definition, Introduction, Parts, Types