Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

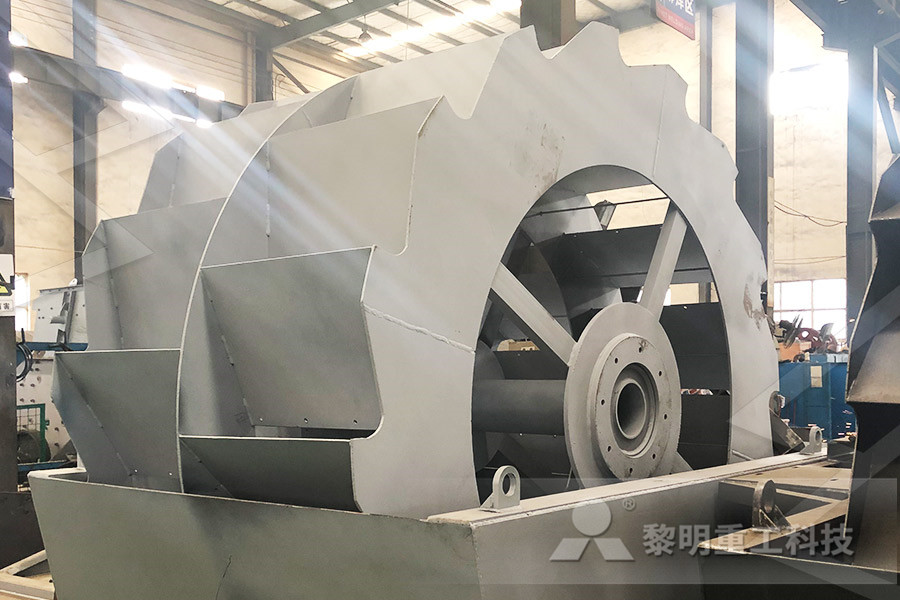

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Ball Mill Capacity Dimensions 2013 Paul O Abbe

Capacity (25% of total) Total Volume WET Working Capacity (60% of total) rpm DRY milling 60% of critical Gear Pinnion Drive used on Larger Mills JH 32014 Talk with the Experts sales@pauloabbe pauloabbe Since 1911 phone 6303503012 fax 6302387584 BAALLLL MMIILLSLLSEach ball mill has a dimension of 30 m x 1,5m and an average capacity of 15 ton/hour of one vertical roller mill having an average capacity of 13 tons/hour and auxiliary systems undefined of 999 0KB of 0KB loaded (0%)ball mill 20 ton capacity mayukhportfoliocotables of tonnage capacity of ball mills Capacity 25 of total Total Volume WET Working Capacity 60 of total rpm DRY milling 60 of critical Gear Pinnion Drive used on Larger Mills JH 32014 Talk with the Experts sales Since 1911 phone fax BAALLLL MMIILLSLLSWe are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone tables of tonnage capacity of ball millsBall mill capacity how to calculateball mill capacity how to calculateHow to size a ball mill design calculator formula mineral mar 31 2016 estimation based on flsmith krebs capacity correlation ideally design value should not exceed 13 psi, tables of tonnage capacity of ball mills Welome to Tables Of Tonnage Capacity Of Ball Millsball Millcylindrical ball mill capacity formulas cylindrical ball mill capacity formulas Grinding Media Wear Rate Calculation in Ball Mill Ball Mills Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800 scylindrical ball mill capacity formulas

table capacity ball mill ideecoza

Mill Grinding found in: GearDrive 04Liter Planetary Ball Mills, Cyclone Mill grinding plates (3371J35) and toothed feed for dry material Capacity 110 lbs per hour at a speed of 30 to 50 rpm Clamp attaches to table tops 13 to 38 mm thickThe results are given in Table 3 wear capacity (ta) and ball mill work index Proposed approaches for optimisation of size distribution of ball mill product are to minimise the product 80 (PDF) A comparison of wear rates of ball mill grinding mediaCAPACITY AND POWER REQUIRE MENTS OF BALL MILLS Approximate Average Capacity, tons/24 hr Size, ft, diam eter X length Approximate Ball Load, 1b Approxi mate Rpm 12 in to 12 in to 48 mesh 65 mesh 14 in to 100 mesh Motor Horse power 35 12 9 5 68 24 35 18 10 1215 42 30 30 20 2025 29 80 55 30 3040 120 29 85 50 4050 125 85 50 25 5060 3 X 4 A Feed Of 150 Tons/day Of Pyrites Must Be Commi CAPACITY AND POWER REQUIRE MENTS OF BALL MILLS Approximate Average Capacity, tons/24 hr Size, ft, diam eter X length Approximate Ball Load, 1b Approxi mate Rpm 12 in to 12 in to 48 mesh 65 mesh 14 in to 100 mesh Motor Horse power 35 12 9 5 68 24 35 18 10 1215 42 30 30 20 2025 29 80 55 30 3040 120 29 85 50 4050 125 85 50 25 5060 3 X 4 A Feed Of 150 Tons/day Of Pyrites Must Be Commi TABLE 5 Mineralogy of Ball Mill Tailings 15 TABLE 6 Soil Saturation Capacity for Lead 20 TABLE 7 Molar Concentrations of Various Elements in Soils 21 Lewistown, Pennsylvania The Ball Mill tailings pile consists of 143,000 tons of heavy metalbearing hazardous waste This is the largest single source of contamination at thatThe Pennsylvania State University The Graduate School

Ball Mill Design/Power Calculation LinkedIn

Dec 12, 2016 The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution The cylindrical ball mill capacity formulas cylindrical ball mill capacity formulas Grinding Media Wear Rate Calculation in Ball Mill Ball Mills Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800 scylindrical ball mill capacity formulasSmall Ball Mill Capacity Sizing Table Do you need a quick estimation of a ball mills capacity or a simple method to estimate how much can a ball mill of a given size diameterlenght grind for tonnage a product P80 size Use these 2 tables to get you close No BWi Bond Work Index required here BUT be aware it is only a crude approximation for most how to increase ball mill capacity by using ball millLarge, Precision, Complex Machining Capabilities in our Machine Shop Class Machine Description Image HBM Parpas Horizontal Mill 60 ton rotary table, 355″ longitudinal, 142″ vertical, 629 cross ram, with five axis head, universal head, facing head Very large complex machining capability VTL Large vertical boring mill with live tooling Machining large hollow jet valve for Large, Precision, Complex Machining Capacities Prime Apr 01, 2017 The grinding circuit used for processing of gold, platinum and base metal ores typically consists of SAG primary mills, followed by ballmills The power drawn by the ballmills is about the same as that of the SAG mill for high capacity milling circuits Table Addition of pebbles to a ballmill to improve grinding

Ball Mills Or Vertical Roller Mills: Which Is Better For

Regarding operations, in a ball mill, the grinding media has a higher rate of wear about the rollers and table in the VRM In ball mills, it is essential to monitor its performance via axial testing to ascertain that the media grading is right and that there are enough topsize media to grind the mill feed materialsJan 07, 2015 ~ Nael Shabana 20104~ 10 Definition of Ball/ Tube Mill: Ball or tube mills are rotating steel cylinders where size reduction of the mill feed is performed by motion of the grinding media Rotation of the mill cylinder raises the pile of mill feed and grinding media to an optimum high, necessary for grinding operationCement mill notebook SlideShareBall mill is the material to be broken, and then smash the key equipment, widely used in cement, silicate products, new building materials, refractory materials, fertilizer, ferrous and nonferrous metal and glass ceramics and other production industries of all kinds of ores and other grindable materials can be Ball Milll Production Line Cost And PriceNov 30, 2015 If the rate of feed increased, coarser product will be obtained and if speed of rotation is increased the fineness for a given capacity is increases During grinding, the balls themselves wear and are continuously replaced by new ones so that mill contains balls of various ages Ball mill produces 1 to 50 ton/hr of powder and energy requirement Ball Mill SlideShareBall milling of graphite with appropriate stabilizers is another mode of exfoliation in liquid phase 21 Graphite is ground under high sheer rates with millimetersized metal balls causing exfoliation to graphene (Fig 25), under wet or dry conditionsFor instance, this method can be employed to produce nearly 50 g of graphene in the absence of any oxidant 22 Graphite (50 g) was ground in Ball Milling an overview ScienceDirect Topics

Cement Grinding Cement Plant Optimization

Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills Closed circuit ball mill with two compartments for coarse and fine grinding are generally found in cement plants for cement grindingLarge, Precision, Complex Machining Capabilities in our Machine Shop Class Machine Description Image HBM Parpas Horizontal Mill 60 ton rotary table, 355″ longitudinal, 142″ vertical, 629 cross ram, with five axis head, universal head, facing head Very large complex machining capability VTL Large vertical boring mill with live tooling Machining large hollow jet valve for Large, Precision, Complex Machining Capacities Prime cylindrical ball mill capacity formulas cylindrical ball mill capacity formulas Grinding Media Wear Rate Calculation in Ball Mill Ball Mills Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800 scylindrical ball mill capacity formulasDec 23, 2013 Practical 1: Title: Ball Milling Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture Introduction: 'Ball milling is a method used to break down the solids to smaller sizes or into a powder APractical 1 : Ball Milling TF Lab 1Apr 15, 2013 particle size and the ball media size: blend of 120 minutes ball milled starch (Table 3) handbook for ball mill grinding is 5 micron particle size achievable in ball mill Gulin provide the is 5 micron particle size achievable in ball mill solution case Particle Size for Grinding with Table Top Ball Mill

Table 1 Shows The Specific Rate Of Breakage S, And

Table 1 shows the specific rate of breakage S, and the values of the breakage distribution function of a mineral ore in a ball mill Table 2 shows the site distribution of the feed Table 1 Specific rate of breakage S and the values of the breakage distribution function blij) of a mineral ore in a ball mill based on 1 min grinding timeRegarding operations, in a ball mill, the grinding media has a higher rate of wear about the rollers and table in the VRM In ball mills, it is essential to monitor its performance via axial testing to ascertain that the media grading is right and that there are enough topsize media to grind the mill feed materialsBall Mills Or Vertical Roller Mills: Which Is Better For Nov 30, 2015 If the rate of feed increased, coarser product will be obtained and if speed of rotation is increased the fineness for a given capacity is increases During grinding, the balls themselves wear and are continuously replaced by new ones so that mill contains balls of various ages Ball mill produces 1 to 50 ton/hr of powder and energy requirement Ball Mill SlideShareBall mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills Closed circuit ball mill with two compartments for coarse and fine grinding are generally found in cement plants for cement grindingCement Grinding Cement Plant OptimizationJan 07, 2015 ~ Nael Shabana 20104~ 10 Definition of Ball/ Tube Mill: Ball or tube mills are rotating steel cylinders where size reduction of the mill feed is performed by motion of the grinding media Rotation of the mill cylinder raises the pile of mill feed and grinding media to an optimum high, necessary for grinding operationCement mill notebook SlideShare

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

The ball size factor, F B, is added to the mall shaft power for mill sizes greater than 33 meters:F↓B – 1102 (d↓max – 125D / 508) kW/t Other Rowland Kjos Power Draw CorrectionsSeveral types of ball mills exist They differ to an extent in their operating principle They also differ in their maximum capacity of the milling vessel, ranging from 0010 liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball millsBall Mill: Operating principles, components, Uses More grinding capacity (approx 20–25% more) than ball mill; lower power consumption (KWh/Ton) than ball mill + pregrinding; Limitations Complex system; Maintenance requirement are higher, In cement grinding, Practically need 2 times annually to reweld roll and table due to excessive wear; Higher overall cost; References Last edited on 28 Vertical roller mill WikipediaCustomers can choose suitable types of ceramic ball mill jars according to the specific gravity, hardness, and capacity of materials It also named the ceramics ball mill, is a small ball mill mainly used for material mixing and grinding considering its products having Ceramic Ball Mill For Grinding Materials FTM Machinery