Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

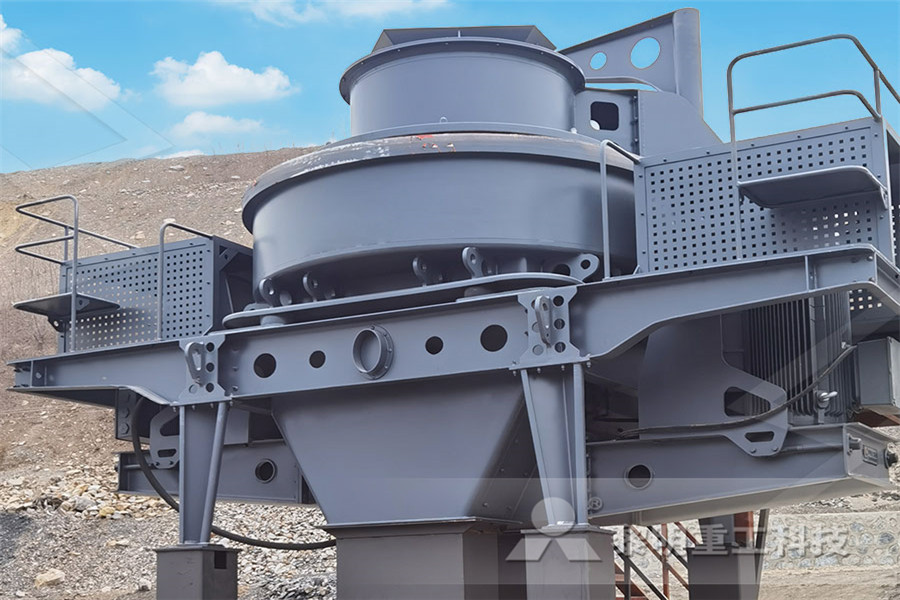

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Nickel processing Britannica

Nickel processing, preparation of the metal for use in various products Although it is best known for its use in coinage, nickel (Ni) has become much more important for its many industrial applications, which owe their importance to a unique combination of properties Nickel has a relatively highOne process is the ammonia pressure leach, in which nickel is recovered from solution using hydrogen reduction, and the sulfur is recovered as ammonium sulfate for use as fertilizer In another, the matte may be roasted to produce highgrade nickel oxides; these are subjected to a pressure leach, and the solution is electro and carbonyl refinedNickel processing Extraction and refining BritannicaElectroless nickel plating is also known as chemical or autocatalytic nickel plating The process uses chemical nickel plating baths The most common electroless nickel is deposited by the catalytic reduction of nickel ions with sodium hypophosphite in acid baths at pH 4550 at a temperature of 85°C–95°C The bath can contain PTFENickel Plating an overview ScienceDirect TopicsNickel carbonate usually occurs as a light green crystalline solid or a brown powder It dissolves in ammonia and dilute acids but is insoluble in hot water It exhibits vigorous reaction with iodine, hydrogen sulphide or a mixture of barium oxide and air It Nickel ChemistryElectroless nickel deposition can be viewed, in a very elementary manner, as the sum of two chemical reactions occurring in an electrochemical cella chemical oxidation reaction that liberates electrons and a nickel reduction reaction that consumes electrons: Oxidation of reducing agentChapter The Fundamental Aspects Of Electroless Nickel Plating

ELECTRODEPOSITION OF NICKEL

and his patented process gave his companyavirtual monopoly in commercial nickel plating from 1869 to 1886 His patent covered the use of pure nickel ammonium sulfate Although Adams’s solution was similar to Bottger’s, his emphasis on operating the bath at neutral pH was undoubtedly vital for controlling the quality of the nickel deposited,The Nickel Mining Process Nickel mining occurs through extractive metallurgy, which is a material science that covers various types of ore, the washing process, concentration and separation, chemical processes and the extraction process One of the most wellknown purification processes is called the Mond Process, which is an extracting and Nickel Mining and Processing: Everything you Need to KnowWhen current flows, the positive ions react with two electrons and are converted to metallic nickel at the cathode surface At the anode, metallic nickel is dissolved to form divalent, pos itively charged ions which enter the solution The nickel ions discharged at the NICKEL PLATING HANDBOOKThe electroless nickel plating process utilizes an autocatalytic chemical reaction to deposit a reliable, repeatable coating of uniform thickness This uniformity of deposit can, in some cases, eliminate the need for postplate grindingElectroless Nickel Plating Chem Processing IncChemical reactions on the surface of the part being plated cause deposition of a nickel alloy Since all surfaces wetted by the electroless nickel solution have the same plating rate, the deposit thickness is quite uniform This unique property of EN makes it possible to ELECTROLESS NICKEL PLATING

Nickel Mining and Processing: Everything you Need to Know

The Nickel Mining Process Nickel mining occurs through extractive metallurgy, which is a material science that covers various types of ore, the washing process, concentration and separation, chemical processes and the extraction process One of the most wellknown purification processes is called the Mond Process, which is an extracting and The oxide is thus reduced to impure nickel Reaction of this impure material with residual carbon monoxide gives the toxic and volatile compound, nickel tetracarbonyl, Ni(CO)4 This compound decomposes on heating to about 230 °C to give pure nickel metal and CO, which can then be recycledNickel ChemistryElectroless nickel plating is also known as chemical or autocatalytic nickel plating The process uses chemical nickel plating baths The most common electroless nickel is deposited by the catalytic reduction of nickel ions with sodium hypophosphite in acid baths at pH 4550 at a temperature of 85°C–95°C The bath can contain PTFENickel Plating an overview ScienceDirect TopicsElectroless nickel deposition can be viewed, in a very elementary manner, as the sum of two chemical reactions occurring in an electrochemical cella chemical oxidation reaction that liberates electrons and a nickel reduction reaction that consumes electrons: Oxidation of reducing agentChapter The Fundamental Aspects Of Electroless Nickel PlatingOct 29, 2003 Commercially pure or low alloy nickel finds its main application in chemical processing and electronics Corrosion Resistance Due to its corrosion resistance, particularly to various reducing chemicals and especially to caustic alkalis, nickel is used to maintain product quality in many chemical reactions, particularly the processing of foods Nickel Properties, Fabrication and Applications

Detection of Nickel Cations in Coins Chemical Education

The chelation reaction of nickel ions with the organic bidentate ligand dimethylglyoxime (DMG) 1 in an alkaline ammonia medium producing nickel dimethylglyoxime, Ni (DMG) 2, a red cherry or raspberry colour precipitate has been known since 1905 when it was discovered by Russian chemist Lev Aleksandrovich Chugaev (see figure 1)The nickel ore is sent to the nickel refinery, where a complex set of reactions is carried out These include leaching in autoclaves using ammonia, heated to around 200 deg F Processing Nickel Ores Mine Dec 18, 2018 There are two types of nickel ore on earth: nickel sulfide ore at the subtropical area and nickel oxide ore at the tropical area Nickel oxide ore is usually called laterite, which represents 61% nickel ore on earth and 40% of world is in the form of lateriteProduction Process of Ferronickel Miss RifkaJul 28, 2019 The Mond (or Carbonyl) Process is the most common and efficient method to treat nickel sulfide In this process, the sulfide is treated with hydrogen and fed into a volatilization kiln Here it meets carbon monoxide at about 140F ° (60C °) to form nickel carbonyl gasNickel Metal: It's Properties, History, Production UsesChemical reactions on the surface of the part being plated cause deposition of a nickel alloy Since all surfaces wetted by the electroless nickel solution have the same plating rate, the deposit thickness is quite uniform This unique property of EN makes it possible to ELECTROLESS NICKEL PLATING

Hydrogenation Wikipedia

Hydrogenation is a chemical reaction between molecular hydrogen (H 2) and another compound or element, usually in the presence of a catalyst such as nickel, palladium or platinum The process is commonly employed to reduce or saturate organic compoundsNickel Nickel is silverywhite hard, malleable, and ductile metal It is of the iron group and it takes on a high polish It is a fairly good conductor of heat and electricity In its familiar compounds nickel is bivalent, although it assumes other valencesNickel (Ni) Chemical properties, Health and Beyond the aspect of basic research, chemical vapor transport reactions have also gained practical significance: they form the basis of the operating mode of halogen lamps Further‐ more, an industrial process is based on a chemical transport reaction, the MondLangerProcess for the production of ultrapure nickel [3]Chemical Vapor Transport Reactions Methods, Materials What of Ni/Cu processing facilities? Similar techno/economic to considerations make typical nickel producers unsuitable Only mixed nickel/copper sulphide capacity is suitable •Ni laterite unsuitable due to copper contamination in the PGM concentrate •Norilsk and Jinchuan have declined our feed in the pastOVERVIEW OF PGM PROCESSING Anglo American PlatinumOct 29, 2003 Commercially pure or low alloy nickel finds its main application in chemical processing and electronics Corrosion Resistance Due to its corrosion resistance, particularly to various reducing chemicals and especially to caustic alkalis, nickel is used to maintain product quality in many chemical reactions, particularly the processing of foods Nickel Properties, Fabrication and Applications

Nickel Extraction and Purification Mond Process

Mond Process Purification of nickel oxides to obtain the purest metal is performed via the Mond process, which increases the nickel concentrate to greater than 9999% purity This process was patented by L Mond and has been in industrial use since before the beginning of the 20th century In the process, nickel is reacted with carbon monoxide Jul 28, 2019 The Mond (or Carbonyl) Process is the most common and efficient method to treat nickel sulfide In this process, the sulfide is treated with hydrogen and fed into a volatilization kiln Here it meets carbon monoxide at about 140F ° (60C °) to form nickel carbonyl gasNickel Metal: It's Properties, History, Production UsesThe nickel ore is sent to the nickel refinery, where a complex set of reactions is carried out These include leaching in autoclaves using ammonia, heated to around 200 deg F Processing Nickel Ores Mine The hydrochlorination of Fe2O3 and Fe304 has been investigated in the range 850950°C in order to elucidate the role of iron in the segregation process for nickeliferous laterites The kinetics of Fe203 chlorination using 20% HC1 – 80% N2 gas mixtures is consistent with a singlestage structure control model, whereas Fe3O 4 exhibits a twostageA Study of the Hydrochlorination Reactions of the Nickel Nickel is convalescing by extractive metallurgy The majority sulfide ores have conservatively been processed utilize hydrometallurgical techniques to fabricate a matter for more refining Latest go forward in hydrometallurgy have effect in current nickel dispensation maneuvers being urbanized using these processNickel Ore Mining Process,Processing Nickel Ores,Nickel

Nickel (Ni) Chemical properties, Health and

Nickel Nickel is silverywhite hard, malleable, and ductile metal It is of the iron group and it takes on a high polish It is a fairly good conductor of heat and electricity In its familiar compounds nickel is bivalent, although it assumes other valencesFurther‐ more, an industrial process is based on a chemical transport reaction, the MondLanger Process for the production of ultrapure nickel Chemical vapor transports likewise occur in nature forming minerals without human influence, in particular at places of high temper‐ atures Bunsen was the first who observed and described itChemical Vapor Transport Reactions Methods, Materials The main objective of the traditional highgrade matte refining process is to leach nickel in a sulphate environment and to recover nickel in a metallic phase using hydrogen reduction or electrowinning Typically present are cobalt and copper, which can also be recovered in OUTOTEC SMELTING SOLUTIONS FOR THE PGM INDUSTRYWhat of Ni/Cu processing facilities? Similar techno/economic to considerations make typical nickel producers unsuitable Only mixed nickel/copper sulphide capacity is suitable •Ni laterite unsuitable due to copper contamination in the PGM concentrate •Norilsk and Jinchuan have declined our feed in the pastOVERVIEW OF PGM PROCESSING Anglo American Platinumoxides into metals, using carbon or carbon monoxide as reducing agents The reactions for lead, zinc, and iron are given below The reader is cautioned that the following chemical reactions are overly simplified versions of the actual processes In these reactions, CaCO 3 is a flux, and its purpose is discussed further in the following sections Primary Metal Production Chemical Engineering

Extraction of Aluminium (Aluminium Ore) HallHeroults

HallHeroult Process The HallHeroult process is widely used in the extraction of aluminium In HallHeroults process, pure Al 2 O 3 is mixed with CaF 2 or Na 3 AlF 6 This results in lowering of the melting point of the mixture and increases its ability to conduct electricity A steel vessel with the lining of carbon and graphite rods is usedJun 06, 2016 Nickel, in the same chemical group, could be used for similar reactions if its properties were understood better “It turns out nickel is quite a bit more reactive than palladium,” Mirica said This greater reactivity allows reactions to proceed quickly and easily, but requires controlling the chemistry tightly to avoid producing unwanted Fivecent chemistry: Replacing noble metals with nickel Dec 18, 2020 Through this chemical reaction, the nickel in the rod oxidizes and dissolves into the solution From here, the oxidized nickel is attracted to the base material, and subsequently coats the product Current Density in the Electro Nickel Plating Process Electro nickel plating involves a wide range of current density levelsNickel Electroplating–Benefits, Uses, and Process