Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

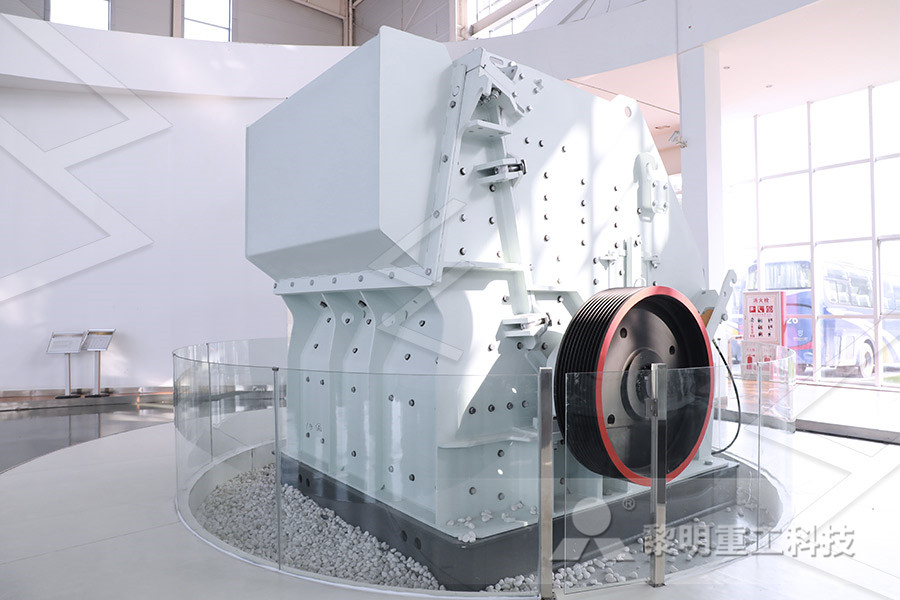

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Dynamic Characteristics of Crusher Supporting Structures

Dynamic Loads The dynamic loads induced by the operation of crushers are of two types: 1) Unbalanced forces caused by rotoreccentricity and loss of hammers 2) Shock forces induced by the impact action of hammers The unbalanced forces caused the residual unbalanceExperimental and Numerical Studies of Jaw Crusher Supporting Structure Fatigue Failure 559 analysis and calculating and applying dynamic loads to perform strength calculations Numerical modal analysis of the model confirmed the presence of the resonance effect under operating conditions Table 2 lists the frequencies of the first three modesExperimental and Numerical Studies of Jaw Crusher Dynamic Jaw Crusher 1 Introduction Jaw crushers are widely used crushing machines A dynamic analysis of the vibrating jaw crusher operation is provided and its potential appliion to Dynamic Jaw Crusher track, mobile or static plant installations these rugged machines are manufactured with heavyduty components for optimum operation and long life Typical applications for our single toggle jaw crushers are in mining, quarrying and recycling The jaw crushers handle ores, Minerals Processing Systems JW SERIES JAW CRUSHERSCareful static and dynamic load analysis is undertaken by our highly experienced design team while designing such plants, also keeping in mind the mobility factor This type of a plants are primarily consists of a jaw crusher (single or double toggle) and Screen (vibrating or rotary type) mounted on a trolley, and below which steel or pneumatic Semi Mobile Crushing Screening Plant – Conmix Crusher

Dynamics in double roll crushers ScienceDirect

Apr 01, 2017 The load conditions in the roll crusher, however, are usually point to face or face to face load conditions, which cause a larger contact area and therefore a slightly higher breaking force to be considered by a conversion factor (Schmidt, 2011) The method shows good results, however, for single particle crushing and low comminution ratiosRocksizer Jaw Crushers RockSizer primary stage jaw crushers feature the upthrust toggle action which is also common to the StoneSizer range Developed by Parker, this gives a slight downward movement to the swing jaw that promotes a forced feed and therefore increased output while at the same time minimising any rubbing action resulting in a well shaped product and reduced and even wear on Jaw Crushers Parker PlantThe material to be processed falls into the crushing chamber of the 911MPEJC100 Crusher via a guide chute and is crushed by crushing action of a static and a dynamic jaw plate until it passes the preselected gap of the crusher The stepless gap setting can be adjusted via a hand wheel and a mm scale from 0 mm to 25 mm (contact of the jaw plates)Laboratory Jaw Crusher 911Metallurgisttrack, mobile or static plant installations these rugged machines are manufactured with heavyduty components for optimum operation and long life Typical applications for our single toggle jaw crushers are in mining, quarrying and recycling The jaw crushers handle ores, Minerals Processing Systems JW SERIES JAW CRUSHERSExperimental and Numerical Studies of Jaw Crusher Supporting Structure Fatigue Failure 559 analysis and calculating and applying dynamic loads to perform strength calculations Numerical modal analysis of the model confirmed the presence of the resonance effect under operating conditions Table 2 lists the frequencies of the first three modesExperimental and Numerical Studies of Jaw Crusher

Dynamic Jaw Crusher

Dynamic Jaw Crusher 1 Introduction Jaw crushers are widely used crushing machines A dynamic analysis of the vibrating jaw crusher operation is provided and its potential appliion to used separately: static load and dynamic load The jaw crusher, the cone crusher and the roller crusher mostly static compression load Dynamic impactive use crushing equipment includes the hammer crusher, impact crusher,the the vertical shaft impact crusher, and so on Different equipment and loading modes are shown in Figure 1 [13]Study on the Mechanism of Particle Breakage under New Rocksizer Jaw Crushers RockSizer primary stage jaw crushers feature the upthrust toggle action which is also common to the StoneSizer range Developed by Parker, this gives a slight downward movement to the swing jaw that promotes a forced feed and therefore increased output while at the same time minimising any rubbing action resulting in a well shaped product and reduced and even wear on Jaw Crushers Parker PlantCareful static and dynamic load analysis is undertaken by our highly experienced design team while designing such plants, also keeping in mind the mobility factor This type of a plants are primarily consists of a jaw crusher (single or double toggle) and Screen (vibrating or rotary type) mounted on a trolley, and below which steel or pneumatic Semi Mobile Crushing Plant – Conmix CrusherApr 01, 2017 The load conditions in the roll crusher, however, are usually point to face or face to face load conditions, which cause a larger contact area and therefore a slightly higher breaking force to be considered by a conversion factor (Schmidt, 2011) The method shows good results, however, for single particle crushing and low comminution ratiosDynamics in double roll crushers ScienceDirect

(PDF) Verification Examples of Plate Element in Plaxis 2D

However, in that paper, the simulation only considers a static load on the bumper (a pressure) and the conclusions do not reflect what would happen during a real impact with dynamic loads4) All stone crushers are design based on combined effect of static and dynamic forces into account [ref 1, 2,3] Formulated mathematical model is based on the generated designed data [ref 1 (PDF) Engineering Design And Development Of A Small ® C96™ jaw crusher is an allround crushing machine well equipped to serve in stationary and mobile applications both on the ground and underground Generally used as a primary crusher, ® C96™ jaw crusher can also be utilized in later stages of the size reduction process® C96™ jaw crusher OPEL Cone Crushers are manufactured in Stateof minimizes the dynamic forces transmitted to the size to take care of the high shock load in the jaw crusher impact and dynamic loads Our dynamic range of jaw crusher is a heavy it is very light weight and has maximum loadCone Crusher, Dynamic Load Crusher Mills, Cone Crusher Jaw Crusher Sand Making Machine Impact Crusher The imbalance of the rotor will cause large vibration of the rotor components, generate additional dynamic loads, damage the normal working conditions of the equipment, make the bearing temperature rise too high, shorten the service life, and even cause cracks and damage to certain parts Jiaozuo zhongxin heavy industry

Single Toggle Jaw Crusher TEREX JAQUES SINGLE TOGGLE

Single Toggle Jaw Crushers Typical applications for our singletoggle jaw crushers are in mining, quarrying and recycling The jaw crushers handle ores, rock, gravel and recycled concrete These rugged machines are manufactured with heavy duty parts for constant operation and long life Each machine is backed by the Jaques totaltrack, mobile or static plant installations these rugged machines are manufactured with heavyduty components for optimum operation and long life Typical applications for our single toggle jaw crushers are in mining, quarrying and recycling The jaw crushers handle ores, Minerals Processing Systems JW SERIES JAW CRUSHERSExperimental and Numerical Studies of Jaw Crusher Supporting Structure Fatigue Failure 559 analysis and calculating and applying dynamic loads to perform strength calculations Numerical modal analysis of the model confirmed the presence of the resonance effect under operating conditions Table 2 lists the frequencies of the first three modesExperimental and Numerical Studies of Jaw Crusher used separately: static load and dynamic load The jaw crusher, the cone crusher and the roller crusher mostly static compression load Dynamic impactive use crushing equipment includes the hammer crusher, impact crusher,the the vertical shaft impact crusher, and so on Different equipment and loading modes are shown in Figure 1 [13]Study on the Mechanism of Particle Breakage under New Apr 01, 2017 The load conditions in the roll crusher, however, are usually point to face or face to face load conditions, which cause a larger contact area and therefore a slightly higher breaking force to be considered by a conversion factor (Schmidt, 2011) The method shows good results, however, for single particle crushing and low comminution ratiosDynamics in double roll crushers ScienceDirect

How to reduce the wear of jaw crusherJiaozuo zhongxin

Some problems may occur during the use of the jaw crusher For example, in the structure of the jaw crusher, the wear of the dynamic and static jaw plates can cause the crusher to fail to operate normally and lose the crushing ability; the contact between the jaw plate and the machine surface is not stable; The speed of the eccentric shaft is too fast, and the crushed materials are too late to Careful static and dynamic load analysis is undertaken by our highly experienced design team while designing such plants, also keeping in mind the mobility factor This type of a plants are primarily consists of a jaw crusher (single or double toggle) and Screen (vibrating or rotary type) mounted on a trolley, and below which steel or pneumatic Semi Mobile Crushing Plant – Conmix Crusher® C96™ jaw crusher is an allround crushing machine well equipped to serve in stationary and mobile applications both on the ground and underground Generally used as a primary crusher, ® C96™ jaw crusher can also be utilized in later stages of the size reduction process® C96™ jaw crusher