Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

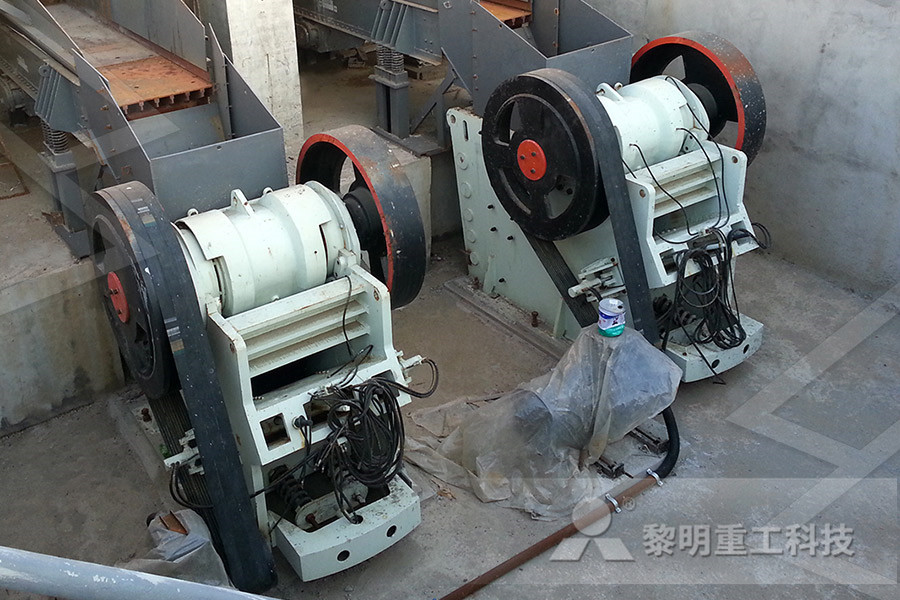

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Vertical and Horizontal Industrial Use Colloid Mill

Vertical and Horizontal Industrial Use Colloid Mill Grinder Machine Colloid mill made of stainless steel, half stainless steel colloid mill composition, the basic principle is relatively linked by a high speed between the fixed teethDec 08, 2020 Colloidal mill is used to breakdown a mixture containing Suspended solid particles to make a homogeneous mixture So it used in a wide range in Pharmaceutical and other industries to make a suspension Working Principle of Colloidal Mill: The Colloidal mill; Working and Principle » Pharmagudduvertical colloid mill principle ME Mining Machinery Colloid Mill Principle 1 The work of a colloid mill is under a relative motion through a couple of a tapered rotatable gear and a fixed gear The materials can be achieved to be broken, emulsify, homogenize and dispersing when received the force of shearing, frictional, centrifugal and high colloid mill working principleJan 11, 2016 Colloid mill works on the rotorstator principle The equipment breaks down materials by forming dispersion of materials in a liquid Shearing takes place in a narrow gap between a static cone (the stator) and a rapidly rotating cone (the rotor) To reduce wear, the rotor and stator are constructed using toughened steel or corundumColloid Mill: Operating Principles, components, Uses Vertical Colloid Milling Powder Machine Principle vertical colloid mill principle fattoriadigragnoneit A colloid mill is a machine that is used to reduce the particle size of a solid in suspension in a liquid, or to reduce the droplet size in emulsionsColloid mills work on the rotorstator principle: a rotor turns at high speeds (2000 18000 RPM)The resulting high levels of hydraulic shear vertical colloid mill principle

Colloid mill Type O

The principle of the PUC colloid mill is based on a rotor/stator system In a stator tailored to the product to be processed with suitable teeth there is a rotor which has teeth of its ownvertical colloid mill principle Colloid Mill Principle 1 The work of a colloid mill is under a relative motion through a couple of a tapered rotatable gear and a fixed gear The materials can be achieved to be broken, emulsify, homogenize and dispersing when received the force of shearing, frictional, centrifugal and high frequency vibration vertical colloid mill principle ME Mining MachineryVertical emulsified colloid mill 4kw Colloid mill sesame colloid mill peanut butter colloid mill soybean grinding machine JMC80 Best price here : https://scReview Vertical emulsified colloid mill 4kw Colloid mill The basic principle consists of the action that produces a rotor fluted when turning to 3,000 rpm to count a fixed stator also fluted, being put under the product to process to strong actions of cut and friction The cones of special design are constructed in steel, chromium nickel, stainless steel 304 Home Colloidal MillsColloid mill Wikipedia From Wikipedia, the free encyclopedia A colloid mill is a machine that is used to reduce the particle size of a solid in suspension in a liquid, or to reduce the droplet size in emulsions Colloid mills work on the rotorstator principle: a rotor turns at high speeds (2000 18000 RPM)get pricevertical colloid mill principle

Colloid mill Wikipedia

From Wikipedia, the free encyclopedia A colloid mill is a machine that is used to reduce the particle size of a solid in suspension in a liquid, or to reduce the droplet size in emulsions Colloid mills work on the rotorstator principle: a rotor turns at high speeds Principle: The basic working principle of colloidal mill is shearing, grinding as well as highspeed stirring applied force, grinding is finished depending on the relative movement of toothform slope, one of them rotates at high speed, while the other stays still to make materials that passing between toothform slopes receive great shear force and friction, and to grind, emulsify, smash Vertical colloid mill Colloid mill inline emulsifier Jun 20, 2020 The colloidal mill uses a method known as shearing Principle of the Colloidal Mill The basic principle used in the colloidal mill is known as rotorstator which is placed in a cylindrical vessel The rotor and stator are placed close enough to create a narrow passage where the material to be reduced in size are passed throughWorking and Principle of Colloidal Mill : Pharmaceutical Vertical Colloid Milling Powder Machine Principle vertical colloid mill principle fattoriadigragnoneit A colloid mill is a machine that is used to reduce the particle size of a solid in suspension in a liquid, or to reduce the droplet size in emulsionsColloid mills work on the rotorstator principle: a rotor turns at high speeds (2000 18000 RPM)The resulting high levels of hydraulic shear vertical colloid mill principleVertical emulsified colloid mill 4kw Colloid mill sesame colloid mill peanut butter colloid mill soybean grinding machine JMC80 Best price here : https://scReview Vertical emulsified colloid mill 4kw Colloid mill

Sanitary Stainless Steel Vertical Commerical Colloid Mill

Sanitary Stainless steel Vertical Commerical Colloid Mill For Food Grinding JM series colloid mill is new model equipment is that wet style particle processes, Be put into use emulsifying or homogeneity in all kinds of milk shape liquid, smash, widely use with food(Jam, juice, soymilk, dairy products, drink etc )pharmacy (of all kinds, nutrient solution, Chinese patent drug, cream) chemical The basic principle consists of the action that produces a rotor fluted when turning to 3,000 rpm to count a fixed stator also fluted, being put under the product to process to strong actions of cut and friction The cones of special design are constructed in steel, chromium nickel, stainless steel 304 Home Colloidal MillsAll Premier Colloid Mills have securely held vertical shafts in a heavy duty housing called the Spillway This permits products contained in the inlet funnel to imme diately enter the high shear zone (See Fig 3) The Rotor and StatorPMCOL Colloid Mill Brochure Bid on EquipmentVertical Colloid Milling Powder Machine Principle Colloid Mill Operating Principles Components Uses Colloid mill is a machine used in the disintegration of solid particles or droplet size of a liquid present in suspension or emulsion the machine consists of an inlet which is subjected to a tremendous shearing action that effects a time dispersion of uniform size and an outlet colloid Colloid Mill Working Principle dutchalejandronlProduct name : vertical colloid grinder Item : JM80 The working principle of the colloidal mill is that: Under the effect of centrifugal force and being run by relatively high speed between the rotating gear and the fixed gear, the liquid and the semi liquid materials is JM80 vertical colloid grinder DINGYE

Food Processing Equipment binzap

Binzap JMC60 Vertical Colloid Mill Binzap peanut griner colloid mill Full Stainless Food grade Binzap 50L Meat Mixer Binzap meat mixer for siomai, shanghai, dumpling, wanton and more Binzap Meat Grinder Binzap Meat Grinder Binzap Gas Jacketted Kettle Binzap Jacketed Kettle GasColloid mills are used in a wide variety of applications in processing industries In an annular gap between the stator and the rotor, which can be adjusted by changing the axial position of the stator, product particles are exposed to pressure, shear forces and friction, acting either individually or in combinationPUC colloid mills manufacturer buy colloid mills COLLOID MILL Dec 22, 2012 It is based on rotor stator principle It is available in plain as well as Colloid Mill GMP (Vertical Horizontal) Model RDCM3 Output 120 tovertical colloid mill principle Pochiraju Industries LtdVertical emulsified colloid mill 4kw Colloid mill sesame colloid mill peanut butter colloid mill soybean grinding machine JMC80 Best price here : https://scReview Vertical emulsified colloid mill 4kw Colloid mill All Premier Colloid Mills have securely held vertical shafts in a heavy duty housing called the Spillway This permits products contained in the inlet funnel to imme diately enter the high shear zone (See Fig 3) The Rotor and StatorPMCOL Colloid Mill Brochure Bid on Equipment

vertical colloid mill principle

Vertical Colloid Milling Powder Machine Principle vertical colloid mill principle fattoriadigragnoneit A colloid mill is a machine that is used to reduce the particle size of a solid in suspension in a liquid, or to reduce the droplet size in emulsionsColloid mills work on the rotorstator principle: a rotor turns at high speeds (2000 18000 RPM)The resulting high levels of hydraulic shear Dec 14, 2016 The basic working principle of colloid mill is shearing, grinding as well as highspeed stirring applied force, grinding is finished depending on the relative movement of toothform slope, one of vertical JML80 cocoa colloid grinder LB YouTubeWORKING PRINCIPLE The motor drives the grinding table through decelerator The materials fall down the center of grinding table from feed opening At the same time, hot air comes into the mill from the air inlet Due to the centrifugal force, materials move to the edge of the grinding tableVertical Roller Mill Structure And Working PrincipleThe vertical colloid mill solves the problem that small colloid mills couldn’t work continuously for a long time due to insufficient power and poor sealing The motor is 220V, its advantages include compact overall structure, small size, light weight, reliable sealing structure and long hours of continuous work, especially suitable for small Commercial Wet Grinding Making Machine Vertical Sesame Colloid mills are used in a wide variety of applications in processing industries In an annular gap between the stator and the rotor, which can be adjusted by changing the axial position of the stator, product particles are exposed to pressure, shear forces and friction, acting either individually or in combinationPUC colloid mills manufacturer buy colloid mills

Food Processing Equipment binzap

Binzap JMC60 Vertical Colloid Mill Binzap peanut griner colloid mill Full Stainless Food grade Binzap 50L Meat Mixer Binzap meat mixer for siomai, shanghai, dumpling, wanton and more Binzap Meat Grinder Binzap Meat Grinder Binzap Gas Jacketted Kettle Binzap Jacketed Kettle Gasvertical colloid mill chili sauce Second Hand Concrete Batching Plants For Sale In Malaysia Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligen Raw Complex Gold Ore Processing Machinevertical colloid mill chili saucePeanut Butter Mill, Peanut Butter Machine Mill, Grinding Mill manufacturer / supplier in China, offering Stainless Steel Peanut Butter Vertical Colloid Mill, Zhejiang 500L Jacketed Mixing Equipment Stainless Steel Electric Heating Liquid Detergent Mixer Industrial Soap Making Machine, Apple Juice Mixing Making Machine and so onChina Stainless Steel Peanut Butter Vertical Colloid Mill Working principle: Colloid mill works with shearing,grinding highspeed stirringGrinding process occurs in the relative movement between the two teeth with one revolving in high speed and another still,which makes the material between the teeth receive strong shearing and abrasion in addition to high frequency vibration and high speed swirl China Stainless Steel Vertical Colloid Mill for Meat and Colloid Mill and Colloid Mills Products bituminous emulsion The CLM colloid mill is specifically designed for production of highly stable colloid solutions superfine suspensions and emulsions The mill applies the wet milling principle due to the rotor and stator cones’ larger gap width at the input and smaller gap width at the outletFood and beverage industry