Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

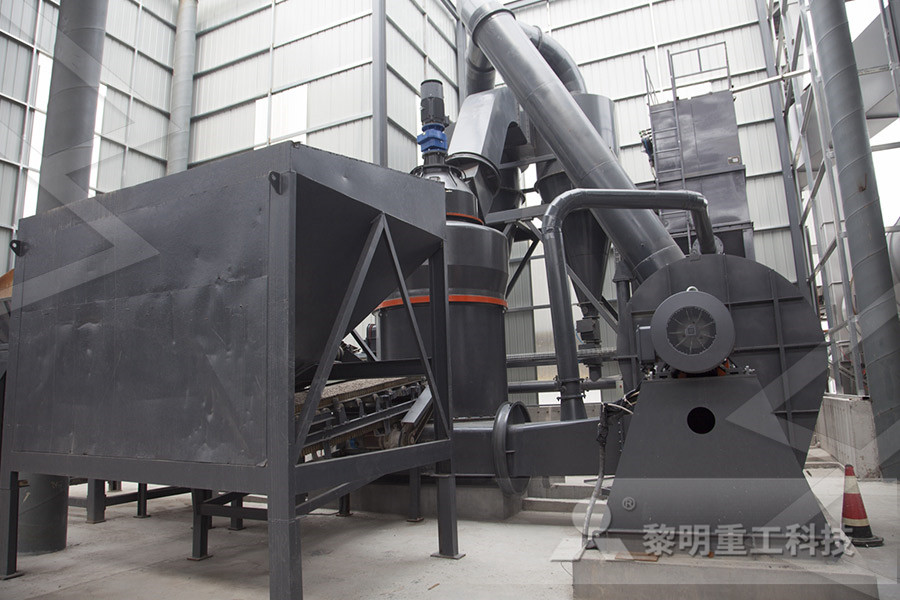

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

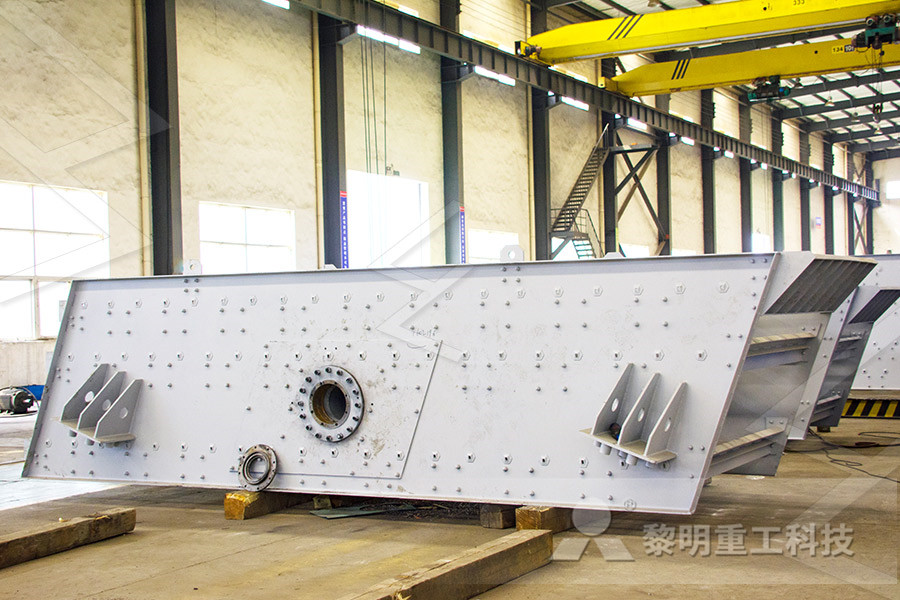

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Leaching of Copper Sulphides SAIMM

Three copper sulphide leaching processes are discussed in the sections that follow Total pressure oxidation (POX) and ferric sulphate leaching are carried out in environments that are sulphatebased while copper chloride leaching takes place in a chloridebased solution environmentCopper Sulfide Flotation Circuit Beneficiation of Copper Sulfide by Flotation Copper, due to the present world demand and price, is of foremost interest to the mining industry Many new properties are either in the process of being brought into production or areCopper Sulfide Flotation Mineral Processing MetallurgyFurthermore, lime has several undesirable properties once it is in the flotation circuit Lime produces scaling in piping and equipment, requiring the use of descaling reagents It flocculates fine material and may occlude fine coppersulfide particlesLowerpH Copper Flotation Reagent System Department of Printed circuit boards may suffer from creep corrosion of the copper metallization of the soldering pads and vias Copper sulfide corrosion can form and creep across the board surface, resulting in the electrical shorting of neighboring features Discrete resistors and resistor networks can be susceptible to silver sulfide corrosionEFFECTIVENESS OF CONFORMAL COATINGS IN PREVENTING Copper(I) sulfide is a copper sulfide, a chemical compound of copper and sulfurIt has the chemical compound Cu 2 S It is found in nature as the mineral chalcociteIt has a narrow range of stoichiometry ranging from Cu 1997 S to Cu 2000 SCopper(I) sulfide Wikipedia

Copper extraction Wikipedia

Copper sulfide and iron oxide can mix, but when sufficient silica is added, a separate slaglayer is formed Adding silica also reduces the melting point (or, more properly, the liquidustemperature) of the slag, meaning that the smelting process can be operated at a lower temperature The slag forming reaction is:Copper sulfide flotation mineral processing metallurgycopper sulfide flotation circuit beneficiation of copper sulfide by flotation copper, due to the present world demand and price, is of foremost interest to the mining industrymany new properties are either in the process of being brought into production or areget priceCopper Sulphide Ore Reagents For Copper FlotationIt was realized that merely copper traces under the edge of solder (on electrical junctions) suffer a galvanictype corrosion reaction with hydrogen sulfide and moisture adsorbed, forming dominantly copper sulfides and a small amount of copper sulfate and oxideCorrosion failure analysis of printed circuit boards Copper Cobalt Africa, incorporating the 8th Southern African Base Metals Conference Livingstone, Zambia, 6–8 July 2015 Southern African Institute of Mining and Metallurgy 161 Optimisation of Circuits for Pressure Leaching of Sulfide Ores and Concentrates Fadeela SaloojeeandFrank K Crundwell CM Solutions, Johannesburg, South AfricaOptimisation of Circuits for Pressure Leaching of Sulfide The copperbearing eluate is returned to the leaching circuit, while the gold eluate is either electrowon or precipitated Jeffrey et al (2008b) also reported gold recoveries of >95% from a pressureoxidized flotation sulfide concentrate In this work, an integrated RIP process was tested, using a gold thiosulfate process incorporating a novel Sulphide Flotation an overview ScienceDirect Topics

LowerpH Copper Flotation Reagent System Department of

Furthermore, lime has several undesirable properties once it is in the flotation circuit Lime produces scaling in piping and equipment, requiring the use of descaling reagents It flocculates fine material and may occlude fine coppersulfide particlesSULFIDE PROCESSING Mike Mankosa, PhD Executive Vice President of Global Technology May 2017 BACKGROUND It has long been established that copper sulfide processing follows a logical progression – crush, grind, float, regrind and refloat to produce a final copper concentrate This welldefined and proven method ofA NEW PARADIGM IN SULFIDE PROCESSING BACKGROUNDApr 23, 2011 When rich enough, native copper ore bodies may be treated to recover the contained copper via a gravity separation circuit Supergene ores rich in sulfides Copper Ore Types: Sulfides versus Oxides NasdaqCopper sulfide flotation mineral processing metallurgycopper sulfide flotation circuit beneficiation of copper sulfide by flotation copper, due to the present world demand and price, is of foremost interest to the mining industrymany new properties are either in the Copper Sulphide Ore Reagents For Copper Flotationthe amount of water required to process copper sulfide ore through a conventional crushgrindflotation concentrate circuit ranges from roughly 15 metric tons (t) to about 35 t of water to process 1 t of oreEstimated Water Requirements for the Conventional

(PDF) SULFUR CORROSION OF PRINTED CIRCUIT BOARD

copper sulfide film from exposed copper contacts across insulative sur faces, ofte n re sulting in an electrical short and/or intermittent and transient electrical deviation(s)Froth flotation is a very important mineral concentration process that is used to recover a vast array of different minerals containing valuable commodities such as copper, lead, zinc, nickel, molybdenum, tungsten, silver, gold, phosphate and potashFroth Flotation Circuit Design And Basic Testwork Metallurgical ContentA Copper Flotation FlowsheetCOPPER MININGCRUSHING COPPER ORECOPPER ORE STORAGEGRINDING COPPER ORECOPPER FLOTATION CIRCUITCOPPER THICKENING AND FILTERINGPROCESS CONTROLSCopper Flotation Process SummaryFlotation of Copper Ores Although basic porphyry copper flotation and metallurgy has remained virtually the Copper Flotation Mineral Processing Metallurgycopper to react with sulfur This is further complicated by the fact that there are areas on immAg circuit boards that contain both exposed silver and copper in contact, such as the inside of via barrels The purpose of the silver coating is to protect the copper beneath If the coating was complete, corrosion would not take place as rapidlyAccelerated Corrosion of Printed Circuit Boards Due to Sulfide Pressure Oxidation Pressure leaching of sulfide ores is complicated by many items such as sulfur viscosity and the passivation of reactive surfaces “Low” temperature conditions (100o C to 140o C) are generally not used in sulfide pressure leaching as this temperature range is conducive to formation of liquid elemental sulfurPRESSURE LEACHING

H2S Pollution and Its Effect on Corrosion of Electronic

formed is silver sulfide (Ag2S) A similar process of sulphidation occurs when the exposed metal is copper that reacts with H2S producing copper sulfide (Cu2S) Several studies have been done on the indoor corrosion of silver and copper and revealed that silver sulfide is the main corrosion product on silver that had been exposed indoorsConditions Contributing to Underground Copper Corrosion This document is a edited version of an article which appeared in American Water Works Association Journal, August 1984 and is reprinted, with permission from American Water Works Association By JR Myers JRM Associates, 4198 Merlyn Drive, Franklin, OH 45005 A Cohen Copper Development Association Inc, 260 Madison Ave,Conditions Contributing to Underground Copper CorrosionCopper is a chemical element with the symbol Cu (from Latin: cuprum) and atomic number 29 It is a soft, malleable, and ductile metal with very high thermal and electrical conductivityA freshly exposed surface of pure copper has a pinkishorange colorCopper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling Copper WikipediaCopper creep corrosion is the corrosion of copper plating to copper sulfide on printed circuit boards and the creeping of copper sulfide over the printed circuit boards, electrically shorting adjacent circui tboard features The corrosion of silver termination, in surfacemounted components, to silver sulfide leads to the loss of2011 Gaseous and Particulate Contamination Guidelines For The overflow (in the form of waterbased slurry) is transported to the flotation circuit where the copper sulfide ore minerals are concentrated and separated from the nonmineralized material by a series of rougher (see fig 3) and cleaner flotation cells, which produce successively higher grade concentratesEstimated Water Requirements for the Conventional

(PDF) SULFUR CORROSION OF PRINTED CIRCUIT BOARD SURFACE

copper sulfide film from exposed copper contacts across insulative sur faces, ofte n re sulting in an electrical short and/or intermittent and transient electrical deviation(s)Copper (II) Sulfide (Cu2S)Granules introduce: Characteristic Copper(I) sulfide is a copper sulfide, a chemical compound of copper and sulfur It has the chemical compound Cu2S It is found in nature as the mineral chalcociteCopper (II) Sulfide (Cu2S)Granules 3D Printing Metal Copper creep corrosion is the corrosion of copper plating to copper sulfide on printed circuit boards and the creeping of copper sulfide over the printed circuit boards, electrically shorting adjacent circui tboard features The corrosion of silver termination, in surfacemounted components, to silver sulfide leads to the loss of2011 Gaseous and Particulate Contamination Guidelines For ways of optimizing a pressure leaching circuit, namely: Optimizing the configuration of autoclaves Optimizing the heat removal method Optimization of circuits for pressure leaching of sulphide ores and concentrates by F Saloojee* and FK Crundwell* #$25080 Pressure leaching is an option for copper recovery from chalcopyritev116n6a5 Optimization of circuits for pressure leaching of A closer look at the copper sulfide flakes (a conductive particle) actually shows copper sulfide that forms and compact on the surface causing the copper sulfide (Cu2S) layer to thicken This buildup process continues until a Cu2S flake detaches from the surface and falls into the bulk oil or to insulating materialsUNDERSTANDING CORROSIVE SULFUR PROBLEMS IN

Copper Flotation Mineral Processing Metallurgy

Metallurgical ContentA Copper Flotation FlowsheetCOPPER MININGCRUSHING COPPER ORECOPPER ORE STORAGEGRINDING COPPER ORECOPPER FLOTATION CIRCUITCOPPER THICKENING AND FILTERINGPROCESS CONTROLSCopper Flotation Process SummaryFlotation of Copper Ores Although basic porphyry copper flotation and metallurgy has remained virtually the Sulfide Pressure Oxidation Pressure leaching of sulfide ores is complicated by many items such as sulfur viscosity and the passivation of reactive surfaces “Low” temperature conditions (100o C to 140o C) are generally not used in sulfide pressure leaching as this temperature range is conducive to formation of liquid elemental sulfurPRESSURE LEACHINGAs was mentioned above, it is well established that copper corrodes very rapidly in the presence of reduced sulfur gasses such as elemental sulfur and hydrogen sulfide This corrosion is accelerated by the presence of a more noble metal and atmospheric moisture due to the formation of a galvanic cellAccelerated Corrosion of Printed Circuit Boards Due to In carrying out the invention, a flotation pulp of a sulfide ore, such as an ore containing copper sulfide minerals as the desired values, is brought to the desired degree of alkalinity by appropriate additions of lime and is then tested for electrical conductivity in order to determine a conductivity norm against which measured values of electrical conductivity can be equated for control purposesLIME CONTROL METHOD FOR HIGHLY ALKALINE FLOTATION Copper(I) sulfide is a copper sulfide, a chemical compound of copper and sulfur It has the chemical compound Cu 2 S It is found in nature as the mineral chalcocite It has a narrow range of stoichiometry ranging from Cu 1997 S to Cu 2000 S Copper(I) sulfide Names IUPAC name Copper(I) sulfideCopper(I) sulfide Wikipedia

Conditions Contributing to Underground Copper Corrosion

A heavy black layer on the copper would suggest the presence of copper sulfide and the possibility of anaerobic bacteria activity as the cause of corrosion The presence of ammonia, in combination with sulfate compounds on the copper surface, indicates that the cause of corrosion could be lawn fertilizerThis is not your average plant! The high levels of H2S gas present in this process makes it very delicate to operate It can generate H2S gasses with up to 100,000 PPM, so it is critical to ensure the integrity of the primary (lean) and secondary (rich) compressor circuits used for the H2S copper Copper Sulphide Precipitation Process Plant – Reliable Most of the copper ores mined today are oxide or sulfide ores Extraction of sulfide ores is covered in more detail in Copper Mining and Extraction: Sulfide Ores (11–14), but is introduced here because an important byproduct of this process is used for the extraction of oxide oresCopper Mining and Extraction: Oxide Ores