Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

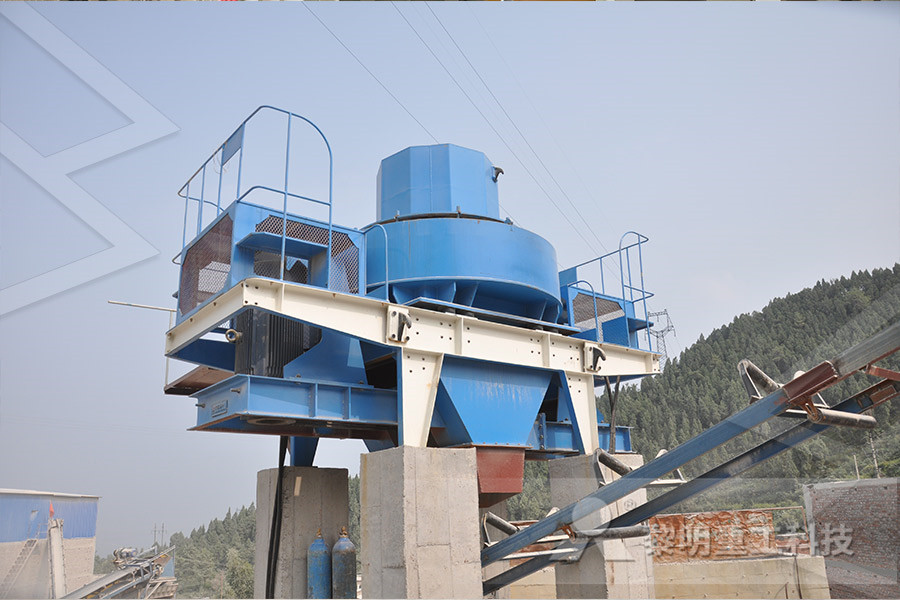

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

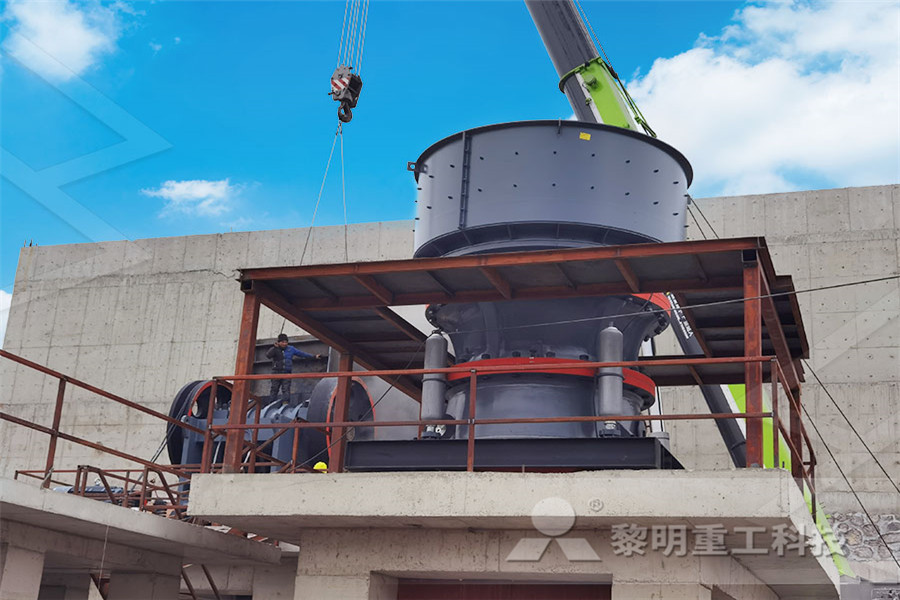

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Grinding Stones McMasterCarr

Dremel Grinding Stones Smoothing and Polishing Stones Smoothing and Polishing Stones Maintain tools, molds, and dies These stones can be used by hand or in power tools with a compatible holder Smoothing and Polishing Stone Sets Each of these sets comes with four differently shaped stonesMar 27, 2017 Grinding valve seats with abrasive stones has been aound about as long as the internal combustion engine In the early days of grinding seats, there were only two abrasive materials to choose from – General Purpose and Finishing – because seats were mostly made of a single material, cast ironThe Daily Grind Grinding valve seats with different 60 Grit Aluminum Oxide Type 5 Internal Grinding Wheel 11/4" Diam x 3/8" Hole x 1" Thick, 25,975 Max RPM, Type 5 Medium Grade, K Hardness, Vitrified Bond, OneSide Recess MSC# Norton Internal Grinding Wheels MSC Industrial SupplyGrinding Spindle: HydroStatic or Roling Bearing Type: Spindle Height: About FL 1150: Work Spindle RPM: 150 to 1800 rpm: Grinding Wheel Spindle RPM: MAX 2,200 rpm (3,000 m/min) Outer Dimension: 2100 * 1900 * 1950H: Weight: 55 Ton: Hydraulic Tank Capacity: 40 LiterGrinding Machines – ORSKOREANorton precision grinding wheels are designed to consistently achieve precise finishes and tight geometry tolerances Whether you work with cutting tools, automotive components like camshafts and crankshafts or aerospace components, our precision grinding wheels will stand up to today's Precision Grinding Wheels Norton Abrasives

Grinding Wheels McMasterCarr

A large grinding surface, combined with a thick layer of rough abrasive removes more material than other wheels They are also known as Type 11 wheels, flaredcup wheels, snagging wheels, and cup stones EasyUse Grinding Wheels Super Abrasives Super Abrasives is amongst the leading Manufacturer Supplier of Abrasives Grinding Wheels, Honing Stones, Internal Grinding Wheels, CBN/ Diamond pressing products, PVA Products, Rubber Bonded Grinding Wheels, Super Finishing Stones and Abrasives for special applicationsSuper AbrasivesTill date super finishing stones are the core strength of the company Super Abrasives is regarded as the pioneer in this niche segment To further establish itself in the bearing industry the company developed special track bore grinding wheelsSUPER ABRASIVES, Bengaluru Manufacturer of Internal The XAP Internal Grinding wheel is a special vitrified bonded CBN quill mounted tool that demonstrates stable and extraordinary accuracy for grinding many manufacturing applicationsNoritake AbrasivesLower your total perpart grinding costs with our selection of toolroom grinding wheels that deliver precision part quality finishes in many applications Available to fit many sizes and specification of machines with speed, quality and finish in mind Review our selection include ID and bearing wheels, cylinder wheels, and other shapesToolroom Grinding Wheels Norton Abrasives

The Daily Grind Grinding valve seats with different

Grinding valve seats with abrasive stones has been aound about as long as the internal combustion engine In the early days of grinding seats, there were only two abrasive materials to choose from – General Purpose and Finishing – because seats were mostly made of a single material, cast ironAdvertisementClick Here to Read MoreAdvertisement Today, []Grinding Wheel Selection for Cylindrical Grinding The listing of grinding wheel specifications for commonly used materials (on page 80) serves the purpose of general information only It may be used as a first approach in grinding wheel selection for cylindrical grinding operations, should more pertinent data, as from comparable past operations GRINDING FEEDS AND SPEEDSCreate smooth surface finishes with Aion's high precision grinding stones Ideal for a wide range of industrial rolls, Aion's Stones ensure uniform finishes Aion grinding and polishing materials simplify conventional lapping or buffing works, helping you reduce overall process timeGrinding/Polishing Stones Shima Products High Quality For the finishing and dressing processes, ATLANTIC can offer both honing and superfinishing stones, which not only produce the finest surfaces and/or precisely defined surface structures with optimised size and geometric accuracy, but also guarantee a high stock removal rateATLANTIC :: Honing stonesATLANTIC GmbH Gartenstr 7 17 53229 Bonn, Germany Tel: +49 (0) 228 4080 Fax: +49 (0) 228 408290 info qRWhaiQeqBuxY5qXhWmwn atlanticbonn dehoningstones atlanticgrindingwheels

Ch 10 grinding and finishing SlideShare

Apr 23, 2017 Super finishing can be effectively done on a stationary workpiece In this the abrasive stones are held in a disc which oscillates and rotates about the axis of the workpiece Internal cylindrical surfaces can also be super finished by axially oscillating and reciprocating the stones on a rotating workpiece; Ans (d) Ans (b) Ans (d) Ans (c Choose from our selection of grinding wheels, including over 3,500 products in a wide range of styles and sizes In stock and ready to shipGrinding Wheels McMasterCarrDiamond and cBN grinding wheels and products are designed for wet or dry precision grinding applications on the hardest materials With Norton diamond and cBN grinding wheels you get high material removal rates, superior form holding and longer wheel lifeDiamond cBN Products Norton Abrasivesgrinding points blue grade : 1 grinding points ruby grade: 1 grinding points brown grade : 1 gunsmithing stone kit: 1 how to use polishing stones by moldshoptools: 1 industrial abrasive sharpening bench stones: 1 knife edge felt wheels : 1 lapping and filing machines air flex shaft operated: 1 metal polishing supplies : 1Mold Shop Tools Product CatalogAbrasive manufacturer since 1957, SERCAP is the specialist in abrasive products for grinding, honing and superfinishing operations When surface finish has to be controlled precisely, you will benefit from SERCAP expertise and unique knowhow in developing and SERCAP Precision abrasives

A Comprehensive Guide to CBN Grinding Wheels Action

Nov 26, 2019 This chipping effect keeps the grinding face of your wheel continually sharp CBN Grinding Wheels A CBN grinding wheel uses Cubic Boron Nitride, or CBN, as its grinding material Cubic Boron Nitride is considered a super abrasive As the name suggests, super abrasives are stronger than normal abrasives like Aluminum Oxide and Silicon CarbideContact Us Super Abrasives No 264, Phase IV, Peenya Industrial Area, Bangalore560 058, INDIA Phone: 9180 : admin@superabrasivesindiaSuper AbrasivesFinishing Stones › Ceramic Super Stones › ARTCO Stones › Boride Stones › Pocket and Bench Stones › Stone Holders › Stoning Oils: – Internal grinding capacity: To 5" diameter wheels, 18" depth • Series 25 – 3 Hp, 220 or 440V, 3 phase, Speeds: 1,750 standard Dumore Tool Post Grinders ARTCO American Rotary Tools Norton Precision Grinding Solutions Set a higher standard for productivity with precision grinding and finishing products from Norton When demanding applications require tight tolerances and part geometries, look to the Norton line of precision grinding wheels and segments for Norton Precision Grinding MSC Industrial Supply CoFinishing Stones › Ceramic Super Stones › ARTCO Stones › Boride Stones › Pocket and Bench Stones › Stone Holders › Stoning Oils: – Internal grinding capacity: To 5" diameter wheels, 18" depth • Series 25 – 3 Hp, 220 or 440V, 3 phase, Speeds: 1,750 standard Dumore Tool Post Grinders ARTCO American Rotary Tools

Norton Precision Grinding MSC Industrial Supply Co

Norton Precision Grinding Solutions Set a higher standard for productivity with precision grinding and finishing products from Norton When demanding applications require tight tolerances and part geometries, look to the Norton line of precision grinding wheels and segments for Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool A wide variety of machines are used for grinding: Handcranked knifesharpening stones (grindstones)Handheld power tools such as angle grinders and die grinders; Various kinds of expensive industrial machine tools called grinding machines; Bench grindersGrinding (abrasive cutting) WikipediaGrinding Wheel Selection for Cylindrical Grinding The listing of grinding wheel specifications for commonly used materials (on page 80) serves the purpose of general information only It may be used as a first approach in grinding wheel selection for cylindrical grinding operations, should more pertinent data, as from comparable past operations GRINDING FEEDS AND SPEEDSATLANTIC GmbH Gartenstr 7 17 53229 Bonn, Germany Tel: +49 (0) 228 4080 Fax: +49 (0) 228 408290 info qRWhaiQeqBuxY5qXhWmwn atlanticbonn dehoningstones atlanticgrindingwheelsgrinding points blue grade : 1 grinding points ruby grade: 1 grinding points brown grade : 1 gunsmithing stone kit: 1 how to use polishing stones by moldshoptools: 1 industrial abrasive sharpening bench stones: 1 knife edge felt wheels : 1 lapping and filing machines air flex shaft operated: 1 metal polishing supplies : 1Mold Shop Tools Product Catalog

Ch10 Grinding and Finishing Grinding (Abrasive Cutting

Grinding Finishing By S K Mondal Abrasive Machining Processes Process Grinding Creep feed grinding Abrasive machining Abrasive water jet Machining Honing Lapping Features Uses wheels, accurate sizing, finishing, low MRR; can be done at high speeds Uses wheels with long cutting arc, very slow feed rate and large depth of cut High MRR, to obtain desired shapes and approximate sizes Apr 23, 2017 Super finishing can be effectively done on a stationary workpiece In this the abrasive stones are held in a disc which oscillates and rotates about the axis of the workpiece Internal cylindrical surfaces can also be super finished by axially oscillating and reciprocating the stones on a rotating workpiece; Ans (d) Ans (b) Ans (d) Ans (c Ch 10 grinding and finishing SlideShareLower your total perpart grinding costs with our selection of toolroom grinding wheels that deliver precision part quality finishes in many applications Available to fit many sizes and specification of machines with speed, quality and finish in mind Review our selection include ID and bearing wheels, cylinder wheels, and other shapesToolroom Grinding Wheels Norton AbrasivesAbrasive manufacturer since 1957, SERCAP is the specialist in abrasive products for grinding, honing and superfinishing operations When surface finish has to be controlled precisely, you will benefit from SERCAP expertise and unique knowhow in developing and SERCAP Precision abrasivesRubber Mounted Points The rubber mounted points use aluminum oxide and rubber adhesives to manufacture It is widely used for finishing, polishing and deburring all kinds of ferrous metals and nonferrous metals, such as manufacturing and repairing metal Rubber Mounted PointsMetal Polishing/Finishing Mounted

ID Grinding Quills: Styles, Materials, and Manufacturing

ID Grinding Quills: Styles, Materials, and Manufacturing Processes Grinding machines from the simplest to the most complex require an ID grinding quill The ID grinding quill is a shaft that’s housed within the grinding machine’s motor and supports and rotates the grinding abrasive wheels