Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

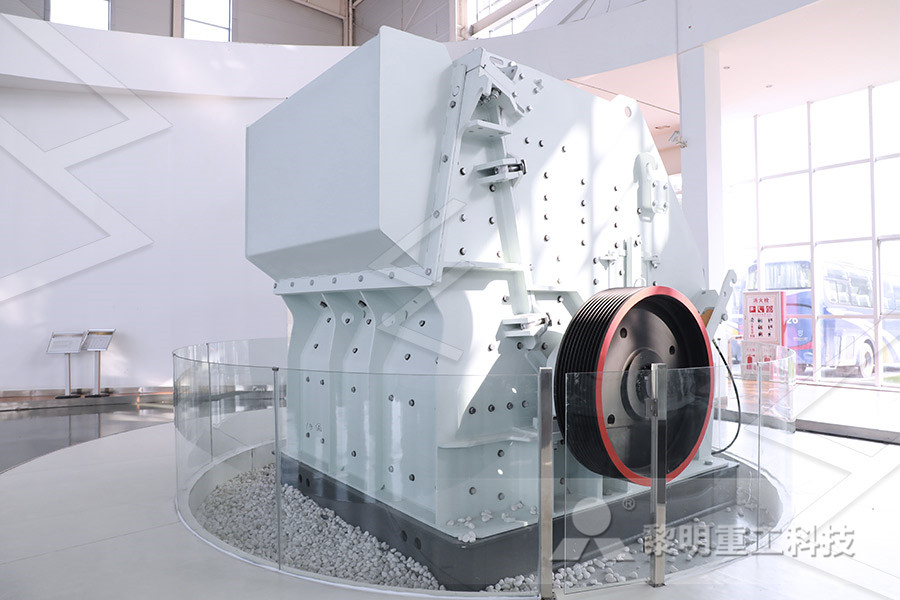

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

CONVEYOR PULLEY SELECTION GUIDE

Tail pulleys commonly serve the purpose of a TakeUp pulley on conveyors of shorter lengths Snub Pulley – A conveyor pulley used to increase belt wrap around a drive pulley, typically for the purpose of improving traction TakeUp Pulley – A conveyor pulley used to remove slack and provide tension to a conveyor belt TakeUp pulleysIn general, the number of crowned pulleys that may be employed to maintain the centered position a flat belt is related, in part, to the span between pulleys vs belt width As this aspect ratio exceeds approximately 3:1, the less likely adverse effects of multiple crowned pulleys will be experienced and the more likely it will be that multiple To crown or not to crown a lagged pulley Habasit Expert Blog A low tension pulley would be a snub or bend pulley with 50% rated belt tension You have to then look at the vector force on a pulley to rate its shaft and shell and bearings If the belt tension is Tmax, and the head pulley has a belt wrap of 180 degrees, then the pulley force is belt conveyor pulleys definition qualityshown in figure A tension applied to the conveyor Adjustment on the head end snub pulley will help train the belt at the point wher e it enters the return run; adjustment on the snub pulley at the tail (if so equipped) will affect travel position of the belt over the tail pulley 2 Return side Belt edges can be damaged if the belt runs Adjusting Mechanical TakeUps on Belt ConveyorsMarine suppliers of Low Tension Snub Pulleys Norfolk Bearings Catalogue Norfolk Bearings specializes in bearings and power transmission equipment Specialises in: Actuators, Couplings, Electric Motors, Pumps and Valve King Shipping Trading Maritime ServicesLow Tension Snub Pulleys suppliers for the Marine

BEND / SNUB PULLEYS Transmin

Bend / Snub Pulleys, either low or high tension, change the belt direction on the return side of the conveyor They are usually lagged to provide longer belt life Features and Benefits – ConveyorPro Standard Pulley Range:Pulley, which is provided to increase/decrease, warp/contact angle of belt on nearby pulley, is called Snub Pulley TakeUp(Tail) Pulley Pulley, which can be moved to keep belt tight, is called takeup PulleyTakeUp Pulley may be a drive pulley or an idler pulleyConveyor Pulley, Drive Pulley, Snub Pulley, TakeUp(Tail Apr 11, 2019 As you can see above, if the drive pulley has 1/2 the diameter of the driven pulley the driven pulley will rotate at 1/2 the speed of the motor In the scenario shown above the drive pulley is 6″ and turning at 1000 RPM and the driven pulley is 12″ and turning at 500 RPM Let’s say we wanted the driven pulley to spin at 600 RPM rather Adjustable Drive Pulley (Sheaves) HVAC SchoolTbc = tension required to overcome belt cleaner drag Te = effective belt tension at drive Tm = tension required to lift or lower conveyed material Tp = tension required to overcome resistance of belt to flexure around pulleys and resistance of pulleys to rotate on their bearings Tpl = tension Calculating Conveyor Power for Bulk Handling Rulmeca CorpIn general, the number of crowned pulleys that may be employed to maintain the centered position a flat belt is related, in part, to the span between pulleys vs belt width As this aspect ratio exceeds approximately 3:1, the less likely adverse effects of multiple crowned pulleys will be experienced and the more likely it will be that multiple To crown or not to crown a lagged pulley Habasit Expert Blog

belt conveyor pulleys definition quality

A low tension pulley would be a snub or bend pulley with 50% rated belt tension You have to then look at the vector force on a pulley to rate its shaft and shell and bearings If the belt tension is Tmax, and the head pulley has a belt wrap of 180 degrees, then the pulley force is Sep 14, 2020 Finetune with the barrel adjuster, located where the cable housing enters the rear derailleur For the best performance, position the guide pulley roughly 6 to 7mm away from the cogsHow to Adjust Rear Derailleur Rear Derailleur Repair Guideshown in figure A tension applied to the conveyor Adjustment on the head end snub pulley will help train the belt at the point wher e it enters the return run; adjustment on the snub pulley at the tail (if so equipped) will affect travel position of the belt over the tail pulley 2 Return side Belt edges can be damaged if the belt runs Adjusting Mechanical TakeUps on Belt ConveyorsSnub/Bend pulley 8000 N 179847 lbf Existing methods for quantifying belt tension of long lowlift conveyors are reviewed in the paper particularly the selection of takeup position (PDF) A Comparison of Effective Tension Calculation for A snub roller supplies belt tracking tension Belt tracking is via the snub roller All tracking is done at the Offset Belt Return Station The drive and tail pulleys of the junction are supplied with nonreplaceable shafts standard Standard shaft diameter is 17/16in Replaceable shaft pulleys are available as an option The tail pulley shafts Installation, Operation and Maintenance Manual

Adjustable Drive Pulley (Sheaves) HVAC School

Apr 11, 2019 As you can see above, if the drive pulley has 1/2 the diameter of the driven pulley the driven pulley will rotate at 1/2 the speed of the motor In the scenario shown above the drive pulley is 6″ and turning at 1000 RPM and the driven pulley is 12″ and turning at 500 RPM Let’s say we wanted the driven pulley to spin at 600 RPM rather Slackside tensionThe area of least tension on a conveyor belt; the lowtension areas will vary on the location of the snub and takeup pulleys; they are completely dependent on the individual conveyor and must be identified for each application Slider barA lowfriction bar, typically used in the construction of a slider bed beltsupport cradleBelt Tech: Conveyor Systems GlossaryBasically no slippage between the belt and the pulley will be appearing Also, the belt should be adapted to the crown of sprocket Any more tension must be prevented because it could rupture the belt seam Remove the right bearing to the exterior to make the head roller advance in a position Conveyor belt tracking adjustment (tension, alignment,)Tbc = tension required to overcome belt cleaner drag Te = effective belt tension at drive Tm = tension required to lift or lower conveyed material Tp = tension required to overcome resistance of belt to flexure around pulleys and resistance of pulleys to rotate on their bearings Tpl = tension Calculating Conveyor Power for Bulk Handling Rulmeca CorpSep 01, 2001 Later, cotton or hemp rope was used with Vgroove pulleys to reduce belt tension This led to the development of the vulcanized rubber Vbelt in 1917 The need to eliminate speed variations led to the development of synchronous or toothed belts about 1950 and the later development of fabricreinforced elastomer materialsPlant Engineering Basics of belt drives

Idler pulleys Rulmeca Rollers

Pulleys are dimensioned according to the characteristics of each conveyor and may be designed to meet a great variety of construction methods According to the position that they occupy in a belt conveyor, the pulleys must withstand the forces imposed by both belt tension and conveyed loadIII All pulleys, snub rollers, carrying idlers, and return idlers must be SQUARE with the frame (perpendicular to belt centerline) and parallel to each other Check by measuring diagonals should be equal IV BELT TENSION must be great enough: A To prevent slippage between the drive pulley #3 Conveyor Belt Tracking Guide Pooley, IncConveyor takeup system The takeup applies tension to the belt to limit the sag between the idlers and prevent slip at the drive pulley The takeup pulley moves to tension the belt Takeup systems are typically gravity, but can be winch, screw or hydraulic jack The typical arrangement has a pulley mounted on a trolleyBelt Conveyor an overview ScienceDirect TopicsSep 15, 2020 The low limit (often marked L) prevents shifts into the spokes; the high limit (marked H) prevents the chain from dropping off the smallest cog The p How to Adjust Rear Derailleur Rear Derailleur Repair Guidehead pulley snub pulley vertical gravity takeup bend pulley return idlers impact idlers Belt tension too high or too low – a close second as a source of reduced accuracy enabling a proper “trough” position that is needed for measuring), which can also limit accuracyWhy does your perfect belt scale underperform?

(PDF) A Comparison of Effective Tension Calculation for

Snub/Bend pulley 8000 N 179847 lbf Existing methods for quantifying belt tension of long lowlift conveyors are reviewed in the paper particularly the selection of takeup position Basically no slippage between the belt and the pulley will be appearing Also, the belt should be adapted to the crown of sprocket Any more tension must be prevented because it could rupture the belt seam Remove the right bearing to the exterior to make the head roller advance in a position Conveyor belt tracking adjustment (tension, alignment,)Note: Belt tension on the junction can be very low as the large pulley face and drive snub allows for significant drive torque to be transmitted to the belt and belt tension is not required for belt tracking After tracking is accomplished, run the conveyor for 2030 minutes to fine tune the tracking Replace the side guides/guards and the outer perforated guards and return the conveyor to serviceInstallation, Operation and Maintenance Manualinsufficient space often exists near the head pulley to allow proper mounting It is usually not recommended that the Excalibur be mounted in a primary position on a head pulley (or snubbar) that is less than 1 in diameter To avoid maintenance issues, the preferred blade contact point is between 7 and 9 o clock, or 3 and 5 o clockI NSTALLATION , O PERATION M AINTENANCE I Pulleys with their axes at other than 90° to the belt path will lead the belt in the direction of the edge of the belt which first contacts the misaligned pulley When pulleys are not level, the belt tends to run to the low side This is contrary to the old "rule of thumb" statement that Smalis Conveyors Conveyor Belt Tracking / Training

ANT!DO NOT DESTROY Installation and Maintenance Manual

minimum position or use a belt puller so lacing pin can be easily inserted The conveyor drive belt has been precut to the proper length and lacing installed at the factory To install follow these steps: W FIGURE 7A FIGURE 7B CAUTION! Excessive slippage will reduce belt life and damage drive pulley lagging Never apply more tension than is The pulley in contact with the belt has a diameter of 8” and a coefficient of static friction of 030 Determine the tension in each part of the belt if the belt is not to slip and: the system uses a flat belt the system uses a Vbelt with a 38o V and the same coefficient of friction 40o 60oBELT AND WRAP FRICTION StaticsA tension is a force along the length of a medium, especially a force carried by a flexible medium, such as a rope or cable The word “tension ” comes from a Latin word meaning “to stretch” Not coincidentally, the flexible cords that carry muscle forces to other parts of the body are called tendons Normal, Tension, and Other Examples of Forces PhysicsAn abnormal sound was heard from an low tension (LT) bend pulley during operation It was reported that the temperature at the nondriveend (NDE) side of the pulleyshell increased up to 83°C The bend pulley was taken out and inspected from outsideBelt Conveyor an overview ScienceDirect Topics