Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

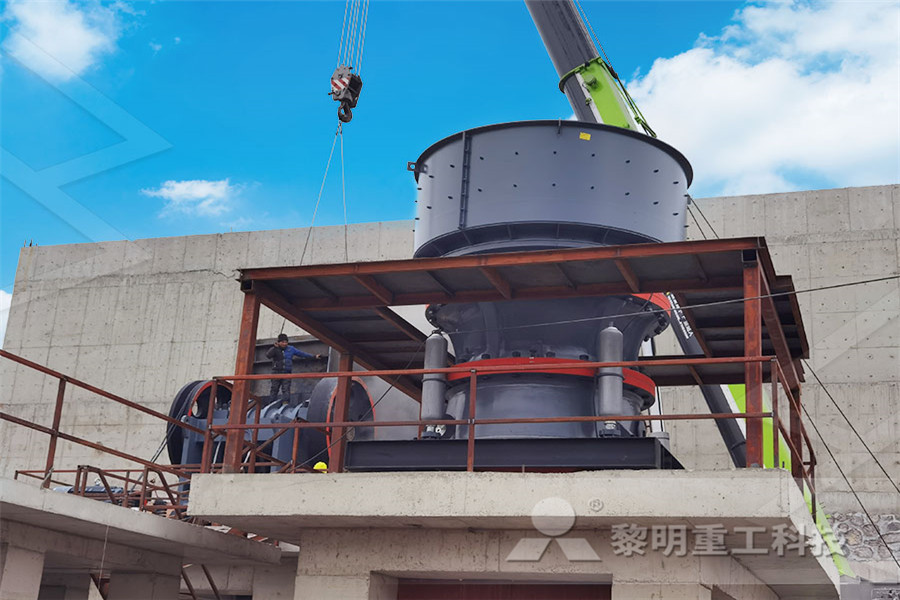

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Tips to maximize crushing efficiency Pit Quarry : Pit

May 13, 2019 Follow the steps outlined in this article to achieve the best crushing efficiency for jaw, cone, gyratory and impact crushers and to ultimately increase profits and reduce fines production By taking these steps, you’re reducing the amount fines produced and adding dollars to your pocketOct 03, 2020 Selecting The Best PrimaryCrusher To The Mixture Application A primarycrusher will be your driving pressure of this accomplishment of your plant life Some tips about just what a thriving procedure for choosing a primary crusher looks like Gyratorycrushers are generally only applied if the targeted amount of generation is significantly Selecting The Best PrimaryCrusher To The Mixture ApplicationJan 23, 2014 SafeSet Application: Gyratory Crusher Control the torque to get the most out of your equipment Torque limiting couplings from Voith limit the torque peaks and associated downtime Gyratory crushers can come to a standstill when uncrushable objects become stuck in the crushing chamber The inertia of the driveline and motor continue the momentumSafeSet Application: Gyratory CrusherAug 03, 2020 A latest extensive, professional market study titled Global Gyratory Crusher Market 2020 by Manufacturers, Type and Application, Forecast to 2025 delivers a lot of details that allow everyone to understand different things without difficulties The report aims to offer opportunities for businesses The report contains estimates on market size, statistical, share, and growth, trends, cost Global Gyratory Crusher Market 2020 Industry Segment best application for gyratory crusher USB2 Top service gyratory crusher Google Patents The apparatus is a gyratory crusher in which all the wear parts can be removed and replaced from the top of the crusher, thus eliminating the need to remove large, heavy parts from below the crusherbest application for gyratory crusher

Gyratory Crusher an overview ScienceDirect Topics

A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening Hammer crushers are used either as a onestep primary crusher or as a secondary crusher for products from a primary crusherThe TS gyratory crusher is distinguished from other gyratory crushers by its revolutionary design which allows major service and maintenance functions to be safely performed The top service feature greatly simplifies safety procedures, reduces costs and helps to increase availability for the equipment over more traditional bottom service crushersCrushing Systems Metallurgical ContentGyratory CrushersGyratory Crusher Capacity TablesSmall Gyratory Crusher Capacity ChartCrusher DriveGyratory CrusherEccentricity Adjustable to Capacity Demands ADVANTAGES OF BOTTOM DISCHARGELOW OPERATING COSTS VERTICAL ADJUSTMENTSMETHODS OF VERTICAL ADJUSTMENTGyratory Crusher Spider Gyratory Crushers Mineral Processing MetallurgyMay 19, 2013 In this video we will see what are the basic features of a Gyratory Crushers Gyratory Crusher are used in Mineral Processing Industry for size reduction of How does a Gyratory Crusher Works Mineral Processing To accomplish this reduction in size takes several steps or stages of crushing and grinding Primary crushing is the first of these stages Generally speaking there are two types of primary crushers, lets compare them: GYRATORY CRUSHER or a JAW CRUSHER Although they don’t look anything like they do have similarities that put them into the same class of crusher Their CRUSHING SPEEDS are the Compare Gyratory Crusher vs Jaw Crusher

Tips to maximize crushing efficiency Pit Quarry : Pit

May 13, 2019 Follow the steps outlined in this article to achieve the best crushing efficiency for jaw, cone, gyratory and impact crushers and to ultimately increase profits and reduce fines production By taking these steps, you’re reducing the amount fines produced and adding dollars to your pocketA gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening Hammer crushers are used either as a onestep primary crusher or as a secondary crusher for products from a primary crusherGyratory Crusher an overview ScienceDirect TopicsAug 03, 2020 A latest extensive, professional market study titled Global Gyratory Crusher Market 2020 by Manufacturers, Type and Application, Forecast to 2025 delivers a lot of details that allow everyone to understand different things without difficulties The report aims to offer opportunities for businesses The report contains estimates on market size, statistical, share, and growth, trends, cost Global Gyratory Crusher Market 2020 Industry Segment Jan 23, 2014 SafeSet Application: Gyratory Crusher Control the torque to get the most out of your equipment Torque limiting couplings from Voith limit the torque peaks and associated downtime Gyratory crushers can come to a standstill when uncrushable objects become stuck in the crushing chamber The inertia of the driveline and motor continue the momentumSafeSet Application: Gyratory CrusherWe offer Gyratory Crusher Wear Plates tailored to your needs and manufactured for increased productivity Here is what sets our Gyratory Crusher Liners apart: (1) Gyratory Crusher Wear Plate design is selected based on customers' application (2) We use high quality materials and a robust Quality Control Program for wear parts Gyratory Crusher Wear Plates

Outotec launches compact largecapacity primary

Outotec is launching an extension to it’s primary gyratory crusher range: The SUPERIOR™ MKIII 6275UG The new crusher, which can be used in different types of applications, provides large capacity with significant savings in CAPEX and operating costsJan 01, 2016 Gyratory crushers can accept 8–10% moisture in operation, but the fine content should be preferably less than 10% The crushing action in gyratory crushers is regarded as rings or ‘helics’ (spirals) of feed down through the crusher of which a single section may be regarded as similar to the jaw crusherGyratory and Cone Crusher ScienceDirectThe apparatus is a gyratory crusher in which all the wear parts can be removed and replaced from the top of the crusher, thus eliminating the need to remove large, heavy parts from below the crusher This is accomplished by constructing the crusher so that the eccentric and the piston assembly can be lifted up and out sequentially The piston assembly then includes all the wear parts within USB2 Top service gyratory crusher Google PatentsThe TS gyratory crusher is distinguished from other gyratory crushers by its revolutionary design which allows major service and maintenance functions to be safely performed The top service feature greatly simplifies safety procedures, reduces costs and helps to increase availability for the equipment over more traditional bottom service crushersCrushing Systems The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily fit into any existing or proposed crushing plant SUPERIOR® gyratory crushers Automation PDF

ESCO Corporation Epoxy Crusher Backing

ESCOBAK ™ is a 100% solid epoxy compound for backing wear liners in cone crushers The smooth consistency of the nonsettling formula allows for easy pouring ESCOBAK™ ensures complete backing over a surface by eliminating gaps that weaken and shorten wearpart life in gyratory crushers and cone crushersGyratory equipment, used in mechanical screening and sieving is based on a circular motion of the machine Unlike other methods, gyratory screen operates in a gentler manner and is more suited to handle fragile things, enabling it to produce finer products This method is Gyratory equipment WikipediaIf you hadn’t had a nightmare about an inanimate object, then allow us to introduce you to the very machine that nightmares are made of in the MineralsMega Machines Gyratory Crusher 🔥 Best New YouTubeThe Effect of Choke Feeding a Gyratory Crusher on Throughput and Product Size J F Dupont (1), J McMullen (1) and D Rose (2) 49th Annual Canadian Minerals Processors Conference, Ottawa, Canada, 2017 ABSTRACT The Detour Lake mine is located 200 km northeast of Timmins, Ontario, CanadaThe Effect of Choke Feeding a Gyratory Crusher on Jan 23, 2014 SafeSet Application: Gyratory Crusher Control the torque to get the most out of your equipment Torque limiting couplings from Voith limit the torque peaks and associated downtime SafeSet Application: Gyratory Crusher

industrial appliion of gyratory crusher

gyratory crusher appliion gyratory crusher application industrial application of gyratory crusher; jaw cone and gyratory crushers in relation to mining; application of gyratory crusher industrial application of jaw crusher is one of the biggest manufacturers in Aggregate Processing Machinery for the industrial appliion of gyratory Jan 01, 2016 Sketch of a Gyratory Crusher (Crusher Size Is Designated by the Gape and Mantle Diameter) Figure 51 is a typical sketch of a large gyratory crusher used as a primary crusher to reduce the size of large pieces of rocks produced during blasting Gyratory and Cone Crusher ScienceDirectNov 10, 2020 Outotec is launching an extension to it’s primary gyratory crusher range: The SUPERIOR™ MKIII 6275UG The new crusher, which can be used in different types of applications, Outotec launches compact largecapacity primary The apparatus is a gyratory crusher in which all the wear parts can be removed and replaced from the top of the crusher, thus eliminating the need to remove large, heavy parts from below theUSB2 Top service gyratory crusher Google PatentsThe TS gyratory crusher is distinguished from other gyratory crushers by its revolutionary design which allows major service and maintenance functions to be safely performed The top service feature greatly simplifies safety procedures, reduces costs and helps to increase availability for the equipment over more traditional bottom service crushersCrushing Systems

Gyratory crusher definition and meaning Collins English

Dec 16, 2020 Gyratory crusher definition: A gyratory crusher is a crusher in which a coneshaped rod rotates in a coneshaped bowl Meaning, pronunciation, translations and examplesThe first considerations are at what point in the process the crusher will be used, the type of material, and the output required Use the table below as a guide Primary Gyratory Crusher B G G Primary Jaw Crusher G B G Primary HSI Impact Crushers P P B Secondary Cone Crushers MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDEThe perfect blend of experience and innovation The SUPERIOR gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory SUPERIOR® gyratory crushers Automation PDF Aug 01, 2016 The basic principle of how does a gyratory crusher work using an animation https://911metallurgist/equipment/crushing/Gyratory Crusher Animation YouTubeSandvik CG800i crushers offer excellent reliability and safer faster maintenance – up to 30% faster than competing crushers A robustly designed onepiece main shaft and reinforced shells are made for tough use The onepiece spherical spider bearing offers at least 5 times longer wear life than than previous Sandvik crushersCG800i Gyratory Crushers — Sandvik Mining and Rock Technology

thyssenkrupp launches nextgen ERC primary crusher

Sep 09, 2019 When it comes to hard rock applications, mining operators rely primarily on Jaw and Gyratory crushers While these are suitable and proven for such applications they require large