Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

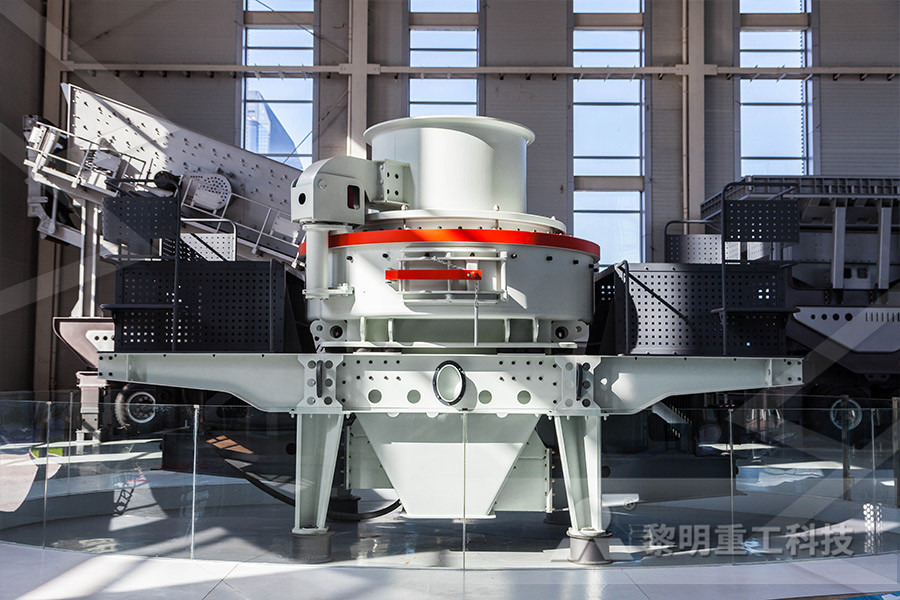

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Iron ore pelletizing systems

Iron ore pelletizing systems Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets These are typically fed to a blast furnace or DRI plant as part of the process to make steel is supplier of both Pelletizing is a process which involves mixing of very finely ground particles of iron ore fines having a size which is less than 200 mesh (0074 mm) with additives like bentonite and then shaping them into near oval/spherical balls having size in the range of 8 mm to 16 mm in diameter by a pelletizer and hardening the balls by firing with a fuelIntroduction to Iron ore Pellets and Pelletizing processes 122213 Pelletizing Technologies There are two main types of pelletizer that are used to produce iron ore pellets at industrial scale, the rotary drum and the disc Besides iron ore agglomeration, these pelletizers can also be used for other materials such as copper ore, gold ore, coal, and fertilizer [12 ]Iron Ore Pellet an overview ScienceDirect TopicsOct 06, 2017 selecting pellet plant technology In: Proceedings of the 6th International Congress on the The use of binders for iron ore pelletizing is required to: (a) increase the pellet strength before (PDF) Iron Ore Pelletizing Process: An OverviewOutotec Traveling Grate Pelletizing is the industry’s leading induration technology for iron ore pellet processing and is designed for a wide range of plant capacities up to 925 million t/a Based on over 60 years’ experience and worldclass RD, our process produces uniform pellets with excellent physical and metallurgical propertiesOUTOTEC TRAVELING GRATE PELLETIZING

Guidelines For Selecting Pellet Plant Technology

As greater amounts of fine iron ore concentrates enter the marketplace, new investments in iron ore pelletizing capacity are inevitable to deliver these concentrates to steel industry consumers When investors assess the two well proven pelletizing technologies, the straight grate and gratekiln, the most appropriate choice may not be Jun 07, 2019 ClevelandCliffs' new $100 million plant on the Iron Range will be the first in the country to use an improved technology that produces a special type of higherquality ironore pelletClevelandCliffs' $100 million plant to use new ore technologyIron ore pellets and Pelletizing processes Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh with additives like bentonite and then shaping them into oval/spherical lumps of 816 mm in diameter by a pelletizer and hardening the balls by firing with a Vale's Pelletizing Plant in OmanPelletizing Technology Milestones 1969 Tubarao 1 Vale, Brazil 20 Mt/a Hematite 1973 Tubarao 2 Vale, Brazil 30 Mt/a Hematite 1978 Mandovi Pellets India 18 Mt/a Limonite 1978 SIDOR Venezuela 2 x 33 Mt/a Limonite 1981 Delta Steel Nigeria 15 mt/a Hematite References 2015 2011 First Circular Pelletizing Plant contracted in India Pro Minerals 1 Circular Pelletizing Technology Metal BulletinPellets are small balls of iron ore used in the production of steel They are made with technology that uses the powder that is generated during the ore extraction process, once Pelleting Plant 8 Vale

Guidelines For Selecting Pellet Plant Technology

As greater amounts of fine iron ore concentrates enter the marketplace, new investments in iron ore pelletizing capacity are inevitable to deliver these concentrates to steel industry consumers When investors assess the two well proven pelletizing technologies, the straight grate and gratekiln, the most appropriate choice may not be Pelletizing of iron ore concentrates in pelletizing discs leads to narrow grain size distributed pellets with smooth surface Pelletizing – how? The process chamber of a pelletizing disc is made by an inclined, rotating, flat cylindrical panIron ore pelletizing technology Mineral ProcessingGUIDELINES FOR SELECTING PELLET PLANT TECHNOLOGY October 2012; Conference: ABM Brazil 2012 Annual Congress A brief introduction to recent developments in iron ore pelletizing is (PDF) GUIDELINES FOR SELECTING PELLET PLANT TECHNOLOGYJun 07, 2019 ClevelandCliffs' new $100 million plant on the Iron Range will be the first in the country to use an improved technology that produces a special type of higherquality ironore pelletClevelandCliffs' $100 million plant to use new ore technologypelletizing iron ore process – Coal processing system Machine Outokumpu Technology Pelletizing technologies for iron ore Roller screens have a major impact on the overall performance of an iron ore pellet plant and on Click Chat NowPelletizing Technologies Plant For Iron Ore

Beneficiation Plants and Pelletizing Plants for Utilizing

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII , Yuta TAKIGUCHI *3 *1 Technology Process Engineering Dept, Iron Unit Div, Engineering Business *2 Plant Engineering Dept, Iron Unit Div, Engineering Business *3 Ironmaking Dept, Kakogawa Works, Iron Steel BusinessMar 20, 2017 This video is for educational purpose (Gurukul Section of our channel) We described here about the process of manufacturing of iron pellets raw material fVisit of Iron Pellet Manufacturing Plant YouTubePelletizing Technology Milestones 1969 Tubarao 1 Vale, Brazil 20 Mt/a Hematite 1973 Tubarao 2 Vale, Brazil 30 Mt/a Hematite 1978 Mandovi Pellets India 18 Mt/a Limonite 1978 SIDOR Venezuela 2 x 33 Mt/a Limonite 1981 Delta Steel Nigeria 15 mt/a Hematite References 2015 2011 First Circular Pelletizing Plant contracted in India Pro Minerals 1 Circular Pelletizing Technology Metal Bulletin is the original technology supplier for GrateKiln systems having acquired the technology from AllisChalmers Features These plants typically produce pellets of a more consistent quality at a lower cost than other types of pelletizing systemsGrate kiln systems Located in Vitória (ES), Plant 8 is an achievementthat allows us to share a sustainable future with all the people of Espírito Santo and Brazilians in general With the opening of the Plant, Espírito Santo consolidates itself as the state that produces and exports the most pellets in the worldPelleting Plant 8 Vale

Pelletizing of Iron Ore Concentrates

Table of ContentsResearch ProgramMajor VariablesApplications of Peat Moss Binder General Application The program of study of pellet binder materials was begun by the ORF in 1963 to examine various Canadian materials as substitutes for bentonite which is imported in large tonnages (199,270 tons in 1969) from the USA for Canadian pellet plant operations Most of the raw bentonite used in Sintering Plant Equipment we are confident that the solutions offered to customers are to be the very latest technology while still maintaining a competitive cost structure A network of belt conveyors carries the pellets going through different stages of the iron ore pelletizing process The reliability of these equipment is importantProducts Iron Ore Pelletizing Equipment Pelletizing Oct 29, 2020 The plant, which will be the fifth large iron ore pelletizing plant delivered by Outotec in China, is based on our environmentally sound traveling grate technology,” says Tobias Stefan, Vice President, Ferrous Heat Transfer business line at Outotec Pellet production at the Zhong Tian plant is estimated to start by the end of 2021 Outotec wins order for a large iron ore pelletizing Technology Trends in Pelletizing Plant Sizes – Investment Costs Operating Costs •Availability Maintainability •Energy Consumption •Emissions Flexibility on Changing Raw Materials •Iron Ore Carriers •Fuels •Recycled Steel Plant Waste Product Quality 8 29042013 World DRI and Pellet Congress, Abu Dhabi50 Years of Iron Ore Pelletizing Experience and InnovationJun 07, 2019 ClevelandCliffs' new $100 million plant on the Iron Range will be the first in the country to use an improved technology that produces a special type of higherquality ironore pelletClevelandCliffs' $100 million plant to use new ore technology

Iron ore pelletizing technology Mineral Processing

Pelletizing of iron ore concentrates in pelletizing discs leads to narrow grain size distributed pellets with smooth surface Pelletizing – how? The process chamber of a pelletizing disc is made by an inclined, rotating, flat cylindrical panThe most commonly employed agglomeration technique is pelletizing by which a mixture of iron ore, water, and binder is rolled up in a mechanical disc or drum to produce agglomerates (green or wet pellets) Figure 1: Iron pellets The pelletizing process is a process which contains numerous subprocesses, or process segmentsThe Iron Pelletizing Process: Part One :: Total Materia GUIDELINES FOR SELECTING PELLET PLANT TECHNOLOGY October 2012; Conference: ABM Brazil 2012 Annual Congress A brief introduction to recent developments in iron ore pelletizing is (PDF) GUIDELINES FOR SELECTING PELLET PLANT TECHNOLOGYpelletizing iron ore process – Coal processing system Machine Outokumpu Technology Pelletizing technologies for iron ore Roller screens have a major impact on the overall performance of an iron ore pellet plant and on Click Chat NowPelletizing Technologies Plant For Iron OreTable of ContentsResearch ProgramMajor VariablesApplications of Peat Moss Binder General Application The program of study of pellet binder materials was begun by the ORF in 1963 to examine various Canadian materials as substitutes for bentonite which is imported in large tonnages (199,270 tons in 1969) from the USA for Canadian pellet plant operations Most of the raw bentonite used in Pelletizing of Iron Ore Concentrates

50 Years of Iron Ore Pelletizing Experience and Innovation

Technology Trends in Pelletizing Plant Sizes – Investment Costs Operating Costs •Availability Maintainability •Energy Consumption •Emissions Flexibility on Changing Raw Materials •Iron Ore Carriers •Fuels •Recycled Steel Plant Waste Product Quality 8 29042013 World DRI and Pellet Congress, Abu DhabiMar 20, 2017 This video is for educational purpose (Gurukul Section of our channel) We described here about the process of manufacturing of iron pellets raw material fVisit of Iron Pellet Manufacturing Plant YouTubeOct 31, 2020 The plant, which will be the fifth large iron ore pelletizing plant delivered by Outotec in China, is based on our environmentally sound traveling grate technology,” says Tobias Stefan, Vice President, Ferrous Heat Transfer business line at Outotec Pellet production at the Zhong Tian plant is estimated to start by the end of 2021 Outotec wins order for a large iron ore pelletizing Mar 21, 2015 Such plants receive the iron ore by rail and/or slurry pipelines Many other pelletizing plants are installed away from the iron ore mines These plants are independent of iron ore mines These plants receive iron ore mostly by rails some plant may receive by long distance slurry pipelineUnderstanding Pellets and Pellet Plant Operations – IspatGuruDec 16, 2020 The slurry pipeline takes ore from the Germano plant to the Point Ubu pellet plant and shipping facility at Espírito Santo on the Atlantic coast At 396km, this iron ore slurry pipeline is the world’s longest and offers environmental safety and 99% average availability The new slurry pipeline built in 2008 also measures 396kmSamarco Iron Ore Mine, Alegria, Brazil Mining Technology

iron ore pelletizing technology

Outotec to deliver technology for the iron ore pelletizing plant in China OUTOTEC OYJ PRESS RELEASE APRIL 11, 2013 at 2:00 PM Outotec to deliver technology for the iron ore pelletizing plant Oct 30, 2020 Circular Pelletizing Technology (CPT) plant from Primetals Technologies in operation at the Basantpur, Keonjhar district site of Pro Minerals Pvt Ltd (Pro Minerals) in the Indian State of Odisha Primetals Technologies, Limited, headquartered in London, United Kingdom, is a pioneer and world leader in the fields of engineering, plant building World´s first Circular Pelletizing Plant from Primetals Outotec has won an order from Bafgh Mineral Complex Iron and Steel Industry Company (BMISCO) for the design and delivery of technology and services for a new iron ore pelletizing plant in Bafgh, Yazd Province, Iran, the Finnish engineering group said MondayOutotec to supply iron ore pelletizing technology to Iran