Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

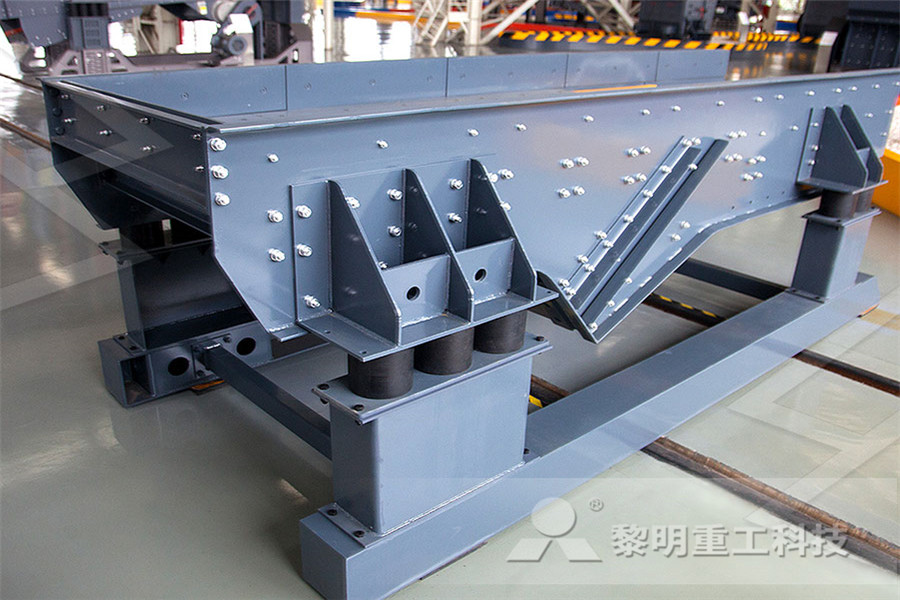

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Vibrating Screen Capacity Calculations – MEKA

The material velocity of a circular vibrating screen can be calculated from the corrected theoretical speed of the product formula written below Example: Determine the material velocity of a screen vibrated at 900 RPM with a 12 mm stroke and 20° degree inclination angle To calculate Figure is multiplied by the sq footage of the screen deck Calculation gives the basic capacity of each deck and the total capacity of the vibrating screen The vibrating screen capacity is determined: Using a standard sizing formula (9 variables)Principles of Screening and Sizingthe vibrating screen Calculating Screen Efficiency Step #1 –Calculate oversize in feed 860 TPH Feed x 73% passing 1 ¼”= 630TPH undersize in feed Step #2 –Calculate TPH undersize in deck oversize 382 TPH Oversize x 40% passing 1 ¼” = 152 TPH undersize in oversThe Basics of Screening Map Your ShowVIBRATING SCREEN – CAPACITY CALCULATIONS Throughput per square foot of screen area is the name of the screen game, and no design engineer wants to be considered short in the area of capacity and efficiency It behooves the buyer/operator to examine and evaluate the data available before committing to any screen type or systemSCREEN CAPACITY CALCULATION VIBFEMAverage ores carrying up to 10% moisture can be screened to 10 mesh without previous drying: beyond that, the vibratory screening should be wet with 3 to 35 ratio of water to ore Approximate Tons thru screen per square foot screening area per 24 hours, wet or dry moisture and screen efficiency Screen Capacity of Crushing Plants Screens are made of perforated steel plates or woven wires What is the Screening Capacity of Vibrating Screen per Area

TECHNICAL NOTES 4 VIBRATING SCREENS Mineral Tech

The screen angle factor K6 The standard inclined screen has an angle of inclination of 15 o Lower angles of inclination increase the projected area of the screen aperture in the horizontal plane and the screen can handle a greater load This is accounted for by capacity factor K6 K 6 10 001( 15) (411) where is the angle of inclination in A variation of a scaled distance equation, v=k(D/√W r)n, where v is the velocity, D is the distance, W r = energy of source, and k = value of velocity at one unit of scaled distance, (D/√W r), has been used successfully for construction vibration settings, particularly for pile driving The value of n Vibration and DistanceTitle: VSMA screen calc method Author: Bryan Created Date: 1/2/2012 11:45:56 AMVSMA screen calc method AggFlow DMB The Shaking Screen: 475 rpm, 1” stroke, zero pitch, 6 deg slope C The Inclined Vibrating Screen: 1200 rpm, 1/4” vertical circle dia D The Horizontal Vibrating Screen: 840 rpm , 1/2” stroke at 45° Each has a 063” dia wire screen with 1/8” clear opening, moving under a particle travellingScreening Theory and Practice Triple/S DynamicsFOUNDATIONS FOR VIBRATING MACHINES Special Issue, AprilMay 2006, of the Journal of Structural Engineering, SERC, Madras INDIA SHAMSHER PRAKASH VIJAY K PURI Professor Emeritus Professor Civil, Architecture and Environmental Civil and Environmental EngineeringFOUNDATIONS FOR VIBRATING MACHINES

Vibrating Screen Working Principle

Metallurgical ContentScreen Vibration PatternsVibrating Screen DesignScreen CapacityVibrating Screen CapacitySCREENINGVibrating Screen CapacityVibrating Screen SPECIFICATIONSFloating Circle MotionWhat It IsHow It WorksMethods of Fastening Vibrating Screen ClothDouble Deck Vibrating Screen—Floor MountedScreen Frame Sizes and ScaleUp Problems and Fundamentals of Vibrating Screen singleplane circulating screen) The main parameter of vibrating devices that affects sieve holes blocking is the toss indicator K The value of K is the ratio of the normal screen acceleration amplitude component to the normal gravitational acceleration component (Fig 1) and is defined as: 22 in s nA K ANALYSIS OF SIEVE HOLES BLOCKING IN A VIBRATING If S is greater than 500 mm 1969", perform the calculation again with K equal to 1600 mm 6299"/s If the newly calculated result gives S less than or equal to 500 1969", set S to 500 1969" Calculation Example (1)2 When using the GLR08L (detection capability d = 45 mm 177" and 8 beam axes) Condition: Industrial application K = 1600 mm 62 Calculating the Safety Distance KEYENCE AmericaThe defined fieldof view (FOV) and pixel width (Δw) determine the number of digitized samples in kspace that must be obtained to reconstruct an image with the desired resolutionAs shown in the diagrams below, FOV is inversely proportional to the spacing between samples in kspaceSpecifically, Δk = 1/FOV From symmetry considerations an inverse relation also holds between pixel width (Δw kspace: FOV Questions and Answers in MRIJul 31, 2018 In this animation we will show what MEKA vibrating screen is consisting of for you to better understand how the vibrating screen worksVibrating screen workiInclined Vibrating Screen, working principle (for

FKL Bearings in Vibrating Screens

The function of a vibrating screen is to sort particulate material made up of a distribution of sizes into specific size groupings Vibrating screens generally handle particles of size between 5 mm and 250 mm They are found in a variety of industries and in a range of processes Its Main Elements: A vibrating screen consists of three main Jun 01, 2017 The tilt angle of the screen is defined as the angle between the screen and the horizontal plane It is one main factor that determines the penetration probability of particles and the screening performance of the vibrating screen (Dong and Yu, 2012, Wang and Tong, 2011, Xiao and Tong, 2013, Zhao et al, 2010)In the literature, the motion of the screen was regarded as the simple harmonic Kinematics and dynamics of a particle on a nonsimple A trommel screen, also known as a rotary screen, is a mechanical screening machine used to separate materials, mainly in the mineral and solidwaste processing industries It consists of a perforated cylindrical drum that is normally elevated at an angle at the feed end Physical size separation is achieved as the feed material spirals down the rotating drum, where the undersized material Trommel screen WikipediaCalculation No CALCULATION SHEET Project No onlinestructuraldesign Project Title: Calc By Date Rev Subject/Feature: Bar spacing (mm) 50 75 100 125 150 175 200 225 250 6 Rebar Bar Area Calculation metric Online Structural DesignBar screens Screens are used in wastewater treatment for the removal of coarse solids Screens are either manually or mechanical cleaned Characteristics of manual bar screen •Bar spacing is in range of 25 cm •The screen is mounted at an angle of 4570 from horizontal •Bars are usually 1 cm thick, 25 wide •Minimum approach velocity in2 Preliminary Treatment

Downspout Gutter Sizing Calculator SMACNA

Calculator Notes and Assumptions Calculator is based on Chapter 1 of SMACNA's Architectural Sheet Metal Manual 7th Edition (ASMM) Rainfall Wizard is based on Table 12 Rainfall Data and Drainage Factors, Page 1213 of the Architectural Sheet Metal Manual 7th EditionChicago Sales Contact c/o ITA, Inc 150 Pierce Rd, Itasca, IL 60143, USA Tel:+1 847 364 1121 Fax:+1 847 364 1183 access InquiriesOpen Area Calculator OKUTANI Co, Ltd• For screen apertures 20 mm (feed size 40 mm), 10 mm (feed size 236 mm) and 06 mm (feed size 14 mm) the most important factor determining the efficiency E is the vibration frequency v (PDF) Some basic Factors affecting Screen Performance in Hooke’s law says that F = –kx where F is the force exerted by the spring, k is the spring constant, and x is displacement from equilibrium Because of Isaac Newton, you know that force also equals mass times acceleration: F = ma These force equations are in terms of displacement and acceleration, which you see in simple harmonic motion in the following forms:How to Calculate the Angular Frequency of a Mass on a If S is greater than 500 mm 1969", perform the calculation again with K equal to 1600 mm 6299"/s If the newly calculated result gives S less than or equal to 500 1969", set S to 500 1969" Calculation Example (1)2 When using the GLR08L (detection capability d = 45 mm 177" and 8 beam axes) Condition: Industrial application K = 1600 mm 62 Calculating the Safety Distance KEYENCE America

ANALYSIS OF SIEVE HOLES BLOCKING IN A VIBRATING

singleplane circulating screen) The main parameter of vibrating devices that affects sieve holes blocking is the toss indicator K The value of K is the ratio of the normal screen acceleration amplitude component to the normal gravitational acceleration component (Fig 1) and is defined as: 22 in s nA K Jun 01, 2017 The tilt angle of the screen is defined as the angle between the screen and the horizontal plane It is one main factor that determines the penetration probability of particles and the screening performance of the vibrating screen (Dong and Yu, 2012, Wang and Tong, 2011, Xiao and Tong, 2013, Zhao et al, 2010)In the literature, the motion of the screen was regarded as the simple harmonic Kinematics and dynamics of a particle on a nonsimple • For screen apertures 20 mm (feed size 40 mm), 10 mm (feed size 236 mm) and 06 mm (feed size 14 mm) the most important factor determining the efficiency E is the vibration frequency v (PDF) Some basic Factors affecting Screen Performance in Chicago Sales Contact c/o ITA, Inc 150 Pierce Rd, Itasca, IL 60143, USA Tel:+1 847 364 1121 Fax:+1 847 364 1183 access InquiriesOpen Area Calculator OKUTANI Co, LtdVibrating Mesh ; Industrial Heavy Screen Weight Calculation of Wire Mesh Arch introduces in this page how to calculate the weight of wire mesh of various materials For wire screen mesh of different materials and different weaving or processing, the weight calculating method is different Following is the formula commonly used for brass Weight Calculator tigerwirenets

How to Calculate Safety Distance for Safety Light Curtains

ANSI Minimum Safety Distance (D S) Calculation A safety professional can help you determine the stopping time (T s) of your machine Then use the following formula to calculate the minimum safety distance for your application D s = K x (T s + T c + T r + T spm) + D pf Where: K = Hand speed constant (63 inches/second)Hooke’s law says that F = –kx where F is the force exerted by the spring, k is the spring constant, and x is displacement from equilibrium Because of Isaac Newton, you know that force also equals mass times acceleration: F = ma These force equations are in terms of displacement and acceleration, which you see in simple harmonic motion in the following forms:How to Calculate the Angular Frequency of a Mass on a Calculation No CALCULATION SHEET Project No onlinestructuraldesign Project Title: Calc By Date Rev Subject/Feature: Bar spacing (mm) 50 75 100 125 150 175 200 225 250 6 Rebar Bar Area Calculation metric Online Structural DesignCalculator Notes and Assumptions Calculator is based on Chapter 1 of SMACNA's Architectural Sheet Metal Manual 7th Edition (ASMM) Rainfall Wizard is based on Table 12 Rainfall Data and Drainage Factors, Page 1213 of the Architectural Sheet Metal Manual 7th EditionDownspout Gutter Sizing Calculator SMACNAThis formula works for all bearings and is widely accepted as the best way to calculate grease quantity Once the required grease volume has been calculated, you will need to determine how often to apply that amount of grease This timeframe is known as the regreasing frequency This calculation is Calculating Grease Quantity, Frequency

Home SMICO Vibratory Screens

SMICO acquired Symons Screens to add a wellknown aggregate presence to its already full line of vibratory screeners, feeders and conveyors SMICO currently manufacturers new parts and screens for Symons Screens and can repair and support all Symons Screens and some Symons designed ScreensThe first, the OSHA formula, is the minimum requirement for the calculation of the safety distance The second formula, the one recommended by Stability Technology, is the ANSI formula, which incorporates additional factors to be considered when calculating the How to Calculate Safety Distances Stability TechnologyFeb 16, 2015 A simplified “cascade arrangement” of screens is shown in Figure below: Screen selection Screen selection is a significant matter All type of screen is not suitable for all kinds of fiber To choice a screen it should be consider the kind of fiber, cost and repair, power consumption, efficiency, capacity, space required etcPulp screening pulp paper mill pulp mill and paper mill