Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

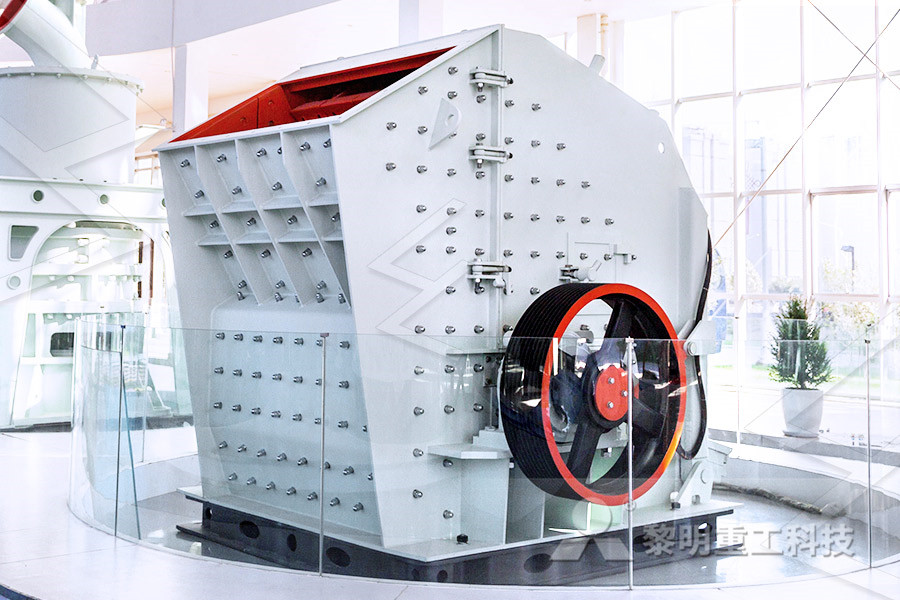

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Flotation Separating Mixtures and Solutions

Flotation Separation is a way of separating mixtures It is used to separate substances by whether they float or sink When a mixture is put into a tube and is stirred, the lighter substance should rise above the heavier substance The substances are then separated and can be removed separatelyJul 01, 2009 The results of reverse flotation separation are listed in Table 3, indicating the LUMO cannot accept feedback electrons to form πbonds Thus the BDDA 2+ cation has difficulty forming a covalent bond with the aluminum atom on the mineral surfaceFlotation separation of the aluminosilicates from diaspore Flotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition—that is, the surfaces are either repelled or attracted by waterFlotation ore dressing BritannicaA nickelcopper sulfide system usually coexists with serpentine in deposits Low nickelcopper recovery and high content of serpentine in concentration adversely affects subsequent metallurgical processes In this study, test data showed different rheological results at various densities When the solid ratio of sulfide to serpentine was 1:1, lower pulp density (20 wt %) contributed to better The Critical Role of Pulp Density on Flotation Separation F LOTATION SEPARATION TECHNICAL FIELD The present invention relates to an improved ?otation apparatus and method for separating a selected constituent from an e?luent of an industrial process in a more cost elfective and e?icient manner BACKGROUND OF THE INVENTION Flotation methods for separating particles, which haveMethod and Apparatus for Flotation Separation

Froth Flotation Process Detailed Explanation With

Flotation is the process of separation of beneficial minerals from a mixture by creating froth on which minerals separate out This method of froth floatation is a method of mineral processing in which different minerals are separated selectivelyJul 01, 2009 The results of reverse flotation separation are listed in Table 3, indicating the LUMO cannot accept feedback electrons to form πbonds Thus the BDDA 2+ cation has difficulty forming a covalent bond with the aluminum atom on the mineral surfaceFlotation separation of the aluminosilicates from diaspore Sep 14, 2011 Froth flotation is a three phase separation process for complex ores based on the manipulation of the difference in hydrophobicity of the solids Suspended, hydrophobic metalrich particles are contacted with, and subsequently combine to, air bubbles — whilst the more hydrophilic gangue particles sink and are recovered to the tails streamA review of froth flotation control ScienceDirectF LOTATION SEPARATION TECHNICAL FIELD The present invention relates to an improved ?otation apparatus and method for separating a selected constituent from an e?luent of an industrial process in a more cost elfective and e?icient manner BACKGROUND OF THE INVENTION Flotation methods for separating particles, which haveMethod and Apparatus for Flotation SeparationJun 30, 2019 Flotation Machine is Important in Flotation Separation Plant 30 Jun/2019 the related processes and ore processing enterprises are in continuous feedback, we should hold on to the whole market opportunities to make diversified development of the flotation tank, transform the equipment from lowend to highend, so as to improve the Flotation Machine is Important in Flotation Separation

FLOATATION YouTube

Jan 04, 2016 Topic: FLOATATION Floatation is the process by which we can remove those insoluble solids from a liquid solid mixture when the solids are lighter than the liquidFLOTATION PROCESS FOR MORE EFFICIENT COAL RECOVERY Froth flotation is a widely used, cost effective particle separation process However, its high performance is limited to a narrow particle size range, eg, between 50 µm and 600 µm for coal and between 10 µm and 100 µm for minerals Outside this range, theCAVITATION NANOBUBBLE ENHANCED FLOTATION Flotation definition is the act, process, or state of floating How to use flotation in a sentenceFlotation Definition of Flotation by MerriamWebsterMineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyMineral processing metallurgy BritannicaSeparation size may be defined either as a specific size in the overflow screen analysis, eg, 5% retained on 65 mesh (212 m m) screen or 45% passing 200 mesh screen (75 m m), or as a d(PDF) Minerals Recovery and Processing

Separation Of Mixture Sieving BYJUS

Sieving is a separation technique based on the difference in particle size The sieve is responsible for retaining the larger particles On top of size, other factors play a role in determining whether a particle will pass through the sieve or not; format of the particle whether the particle will fall where there is an opening or on the mesh of flotation separation A concentration process where by finely ground ore is dispersed in water containing a flotation reagent which causes selected minerals to become hydrophobic Aeration and agitation of the suspension allows hydrophobic particles to float while unaffected minerals sink The floating particles are skimmed off or overflow the flotation cellFlotation Process EncyclopediaPlastics are widely used in everyday life as a useful material, and thus their consumption is growing at a rate of about 5% per year in Korea However, the constant generation of plastic wastes and their disposal generates environmental problems along with economic loss In particular, mixed waste plastics are difficult to recycle because of their inferior characteristics A laboratoryscale Application of Electrostatic Separation to the Recycling Filtration is a physical, biological or chemical operation that separates solid matter and fluid from a mixture with a filter medium that has a complex structure through which only the fluid can pass Solid particles that cannot pass through the filter medium are described as oversize and the fluid that passes through is called the filtrate Oversize particles may form a filter cake on top of Filtration WikipediaJul 01, 2009 The results of reverse flotation separation are listed in Table 3, indicating the LUMO cannot accept feedback electrons to form πbonds Thus the BDDA 2+ cation has difficulty forming a covalent bond with the aluminum atom on the mineral surfaceFlotation separation of the aluminosilicates from diaspore

Froth Flotation Process Detailed Explanation With

Apr 06, 2020 In ore/mineral beneficiation, froth flotation is a method by which commercially important minerals are separated from impurities and other minerals by collecting them on the surface of a froth layer Flotation is the process of separation of beneficial minerals from a mixture by creating froth on which minerals separate outF LOTATION SEPARATION TECHNICAL FIELD The present invention relates to an improved ?otation apparatus and method for separating a selected constituent from an e?luent of an industrial process in a more cost elfective and e?icient manner BACKGROUND OF THE INVENTION Flotation methods for separating particles, which haveMethod and Apparatus for Flotation Separation91 TECHNICAL NOTES 9 FLOTATION Flotation is the most widely used mineral separation method It is the preferred method of mineral recovery for many of the most important minerals that are recovered and large tonnages of ore are processed by flotation annuallyTECHNICAL NOTES 9 FLOTATION Mineral TechMay 01, 2002 The commercial frother, MIBC (4methyl2pentanol; (CH 3) 2 CHCH 2 CH(OH)CH 3; the molecular weight is 10218) was used in all flotation tests and during the combination of sinkfloat separation and flotation experiments After the separation, the collected products were washed, dried and weighed then the grade and the recovery were calculated based on the mass bination of sink–float separation and flotation The flotation plant design was based on extensive benchscale testwork (including locked Samples are selected for initial reagent definition to achieve the desired mineral separation Separation may be a simple bulk float (iepyritic gold ores, some copper ore with negligible pyrite) or as is the case for polymetallic ores, a complex three INTERPRETATION OF FLOTATION DATA FOR THE DESIGN OF

Flotation Method in Archaeology ThoughtCo

Mar 01, 2019 The earliest published use of water separation dates to 1905, when German Egyptologist Ludwig Wittmack used it to recover plant remains from ancient adobe brick The widespread use of flotation in archaeology was the result of a 1968 publication by archaeologist Stuart Struever who used the technique on the recommendations of botanist Hugh separation techniques, froth flotation employs a relatively high gas flowrate under turbulent conditions Next to froth flotation, the most useful foam separation technique is precipitate flotation where the species to be separated is first precipitated, usually by a change of solution pH, and thenSeparation Using Foaming Techniques Columbia UniversityJan 30, 2015 INTRODUCTION Flotation is the separation of particles from a mixture by causing some particles to collect on the surface of bubbles Floatation is an extractive process where various minerals can be selectively extractedFloatation SlideShareIn a conventional flotation plant no attempt is made to engineer a perfect separation in one stage Instead, both fractions leaving the rougher are retreated at least once in “cleaner” and “scavenger” cells, respectively Scavenger cells, in effect, prolong the flotation time, while competition for Industrial Plant Flotation Machines in BanksFoam flotation is a process used worldwide to separate metallic and nonmetallic minerals from extracted ore It is probably the single most important operation used in the mining industry in the world today In the United States, for example, over onethird of the mineral concentrates produced are obtained using flotation Foams in mineral flotation and separation processes

Dissolved Air Flotation System (DAF) Hoffland

Dissolved Air Flotation Systems HEI manufactured dissolved air flotation systems (DAF) efficiently separate total suspended solids (TSS) and fats, oils, and grease (FOG) particles from industrial effluents Air is dissolved in the treated water by the addition of compressed air to Flotation is a process in LiquidSolid Separation technology whereby solids in suspension are recovered by their attachment to gas (usually air) bubbles, usually with objective of removing the solids from the liquid The particles most effectively removed are in the size range from 10 to 200 μmFLOTATION ThermopediaJan 04, 2016 Topic: FLOATATION Floatation is the process by which we can remove those insoluble solids from a liquid solid mixture when the solids are lighter than the liquidFLOATATION YouTube