Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

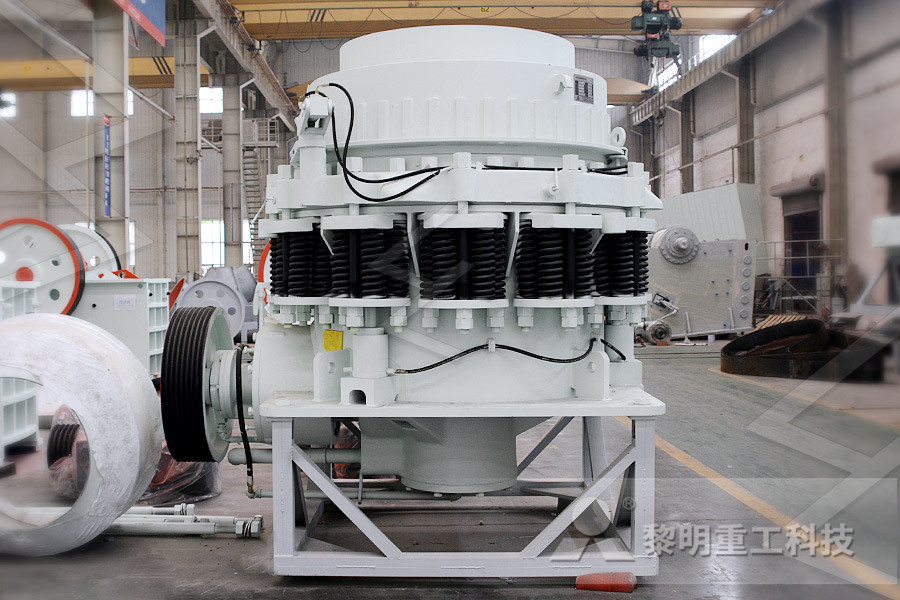

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

drill flute grinding machine, drill flute grinding machine

DBSLD410 Automatic Drill Bit Flute Grinder Drill Bit Flute Grinding Machine Highly automatic Up to 5 years warranty US $65000$65000 / Set 1 Set (Min Order)Purchase 2 Flute 90°Angle2 Flute 90°Angle "DrillMill" Single End Mill Drill FC61 Drill Flute and Clearance Machine PS52 Drill Point and Split Point Machine Other Available Drill Machines P500 Drill Point Machine SP22 Drill Split Point Machine SP7S Drill Split Point Machine F250 / F300 Drill Flute Machine F500 / F600 Drill Flute Machine C500 Drill Clearance Machine C770 Drill Clearance MachineDrill Machines – NormacMultistation grinding machine for highly efficient grinding of large batches of tools with the same point geometry The machine is suitable for tool diameters from 1850 mm to 12000 mm and tool lengths up to approx 1000 mmSingle flute gundrills Botek USAHIGH PERFORMANCE PRODUCTS FOR FLUTE POLISHING Shank tools such as end mills, reamers, drills and stepped tools vary in their geometry and design A specific sequence of applications is created by the geometry This would include flute grinding, grinding clearance angles and gashingFlutePolish Grinding Wheel Winter Shank Tools Norton

Automatic flute grinding machine Spiral Step Tool Company

An automatic grinding machine adapted to cut and relieve spiral drill flutes and perform analogous formrelieving operations requiring helical advance of the work, wherein a linearlymoving carriage travels a rotary spindle and its work chuck relative to a grinding wheel in programmed duty cycles under control of logic circuitry with optional manual override controlSep 01, 2015 In the manufacturing of drills, the flute grinding process is much different than on end mills The contact area is higher and the force/grit is much higher There are two methods companies use to flute these tools Method 1 utilizes straight faced wheels as this greatly reduces the amount of grinding wheel inventory used for many sized toolsEffective flute grinding Cutting Tool EngineeringDec 16, 2015 I rebuilt a couple of centerless grinders for Viking Drill and ToolAmerica's Finest HighSpeed Steel Cutting Tools™ They grind the flutes inside a drill and tap flute grinding machine using diamond wheels and flood cutting oil coolant Much like this machine that's is doing a tap Viking may make you some blanksGrinding flutes into HSS drill blanks for custom form drillsDrilling is a cutting process that uses a drill bit to cut a hole of circular crosssection in solid materials The drill bit is usually a rotary cutting tool, often multipointThe bit is pressed against the workpiece and rotated at rates from hundreds to thousands of revolutions per minuteThis forces the cutting edge against the workpiece, cutting off chips (swarf) from the hole as it is Drilling WikipediaFlute grinding is the most time consuming and thus most cost intensive manufacturing step during tool grinding (taps, drills, end mills) production In recent years, tool grinding machines have becFlute Grinders Grinding Machines MachineTools

Single flute gundrills Botek USA

Multistation grinding machine for highly efficient grinding of large batches of tools with the same point geometry The machine is suitable for tool diameters from 1850 mm to 12000 mm and tool lengths up to approx 1000 mmThe largest distributor of stone fabrication tools, equipment and supplies in the US, and provider of top quality products to the concrete, tile and monuments marketsFlute Grinding and Polishing Power Tools Accessories The Oliver Model 600 Drill Point Grinder is the ideal machine for sharpening large diameter bits from 1/2" to 3" (76 mm), with the option to increase the maximum drill size to 4" (102 mm) The machine easily handles two flute, three flute and four flute drill bitsLarge Drill Grinder for up to 4 inch Drills : Oliver 600 3With diamond grinding wheel, it can be equipped directly with an accurate angle and long service life 4The electrically controlled and powerful DC motor: stable frequency, strong horsepower and long service life 5The machine is specialized in resharpening end mill, it can grind 2flute, 3flute and 4flute,MRCM MR X1 multi functional end mill sharpener UFG MACHINE SPECIFICATIONS FLUTE GRINDERS Flute grinding is the most time consuming and thus most cost intensive manufacturing step during tool grinding (taps, drills, end mills) production In recent years, tool grinding machines have become more compact, axis path lengths have reduced, and machine controls have become more efficientflute grinding machines for drills Schoon water voor

Computer Aided Design of Grinding Wheel for Drill Flute

During the flute grinding, the grinding wheel rotates inplace with the drill simultaneously rotating about and moving down its axis The dual motion of the drill controls the helix angle of the flute and the position and profile of the grinding wheel controls the crosssection of the drill fluteTypes Linear cutting tools include tool bits (singlepoint cutting tools) and broachesRotary cutting tools include drill bits, countersinks and counterbores, taps and dies, milling cutters, reamers, and cold saw blades Other cutting tools, such as bandsaw blades, hacksaw blades, and fly cutters, combine aspects of linear and rotary motion Cutting tools with inserts (indexable tools)Cutting tool (machining) WikipediaFree standard UPS ground shipping for WEB orders over $300 NET within the lower 48 states!* *Free freight offer does not include specials, Cushman Chucks HUOT productsMichigan Drill CorporationJan 13, 2004 Such drills, even new ones, will not drill efficiently or accurately However, dubbing such drills will dress out the difference, leaving dubbed lips at a precisely opposite 180degree position from each other and in uniform configuration of flutetoflute surfacesChoose The Best Drill Point Geometry Modern Machine ShopFlute grinding is the most time consuming and thus most cost intensive manufacturing step during tool grinding (taps, drills, end mills) production In recent years, tool grinding machines have become more compact, axis path lengths have reduced, and machine controls have become more efficientUniversal Flute Grinders ITM – International Tool Machines

2 Flute 90°Angle "DrillMill" Single End Mill Drill

Purchase 2 Flute 90°AngleDesigned for chamfering, milling, and some spotting applications, Micro 100's solid carbide Drill / End Mills are offered in 2 and 4flute styles and in both uncoated and AlTiN coated styles Designed for chamfering, milling, and some spotting applications 2 flute design effective in Drill/End Mills 2 4 Flute Micro 100Srushti Autotech Offering Drill Bit Flute Grinding Machine, ग्राइंडिंग मशीन in Bengaluru, Karnataka Get best price and read about company Get contact details and address ID: Drill Bit Flute Grinding Machine, ग्राइंडिंग मशीन Flute grinding is the most time consuming and thus most cost intensive manufacturing step during tool grinding (taps, drills, end mills) production In recent years, tool grinding machines have becFlute Grinders Grinding Machines MachineToolsPurchase 2 Flute 90°Angle2 Flute 90°Angle "DrillMill" Single End Mill Drill

Large Drill Grinder for up to 4 inch Drills : Oliver 600

The Oliver Model 600 Drill Point Grinder is the ideal machine for sharpening large diameter bits from 1/2" to 3" (76 mm), with the option to increase the maximum drill size to 4" (102 mm) The machine easily handles two flute, three flute and four flute drill bitsWe know that we only thrive if we will guarantee our combined cost competiveness and highquality advantageous at the same time for Drill Flute Grinding Machine, Small Vertical Drilling Machine, Wood Cnc Router 1300mm X 2500mm, Long Hole Drill Machine, We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!Drill Flute Grinding Machine China Manufacturers