Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

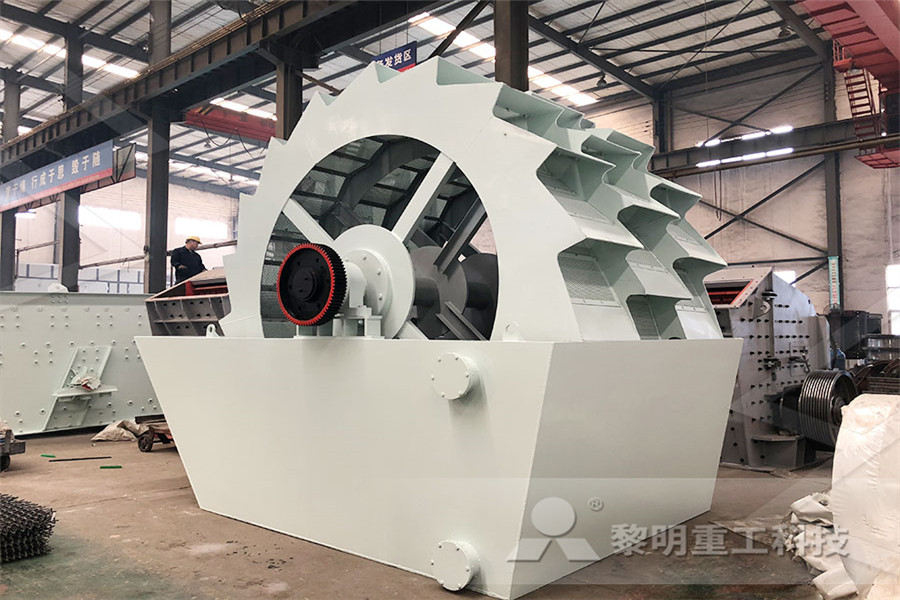

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Construction, Working and Maintenance of Crushers for

5 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials In a nonreversible hammer mill with screen bars, shown in above figure, material is broken first by impact between hammers and breaker plates and then by Here Crusher Maintenance Safety Tips please understand well depend it YJMT Agricultural Machinery, All Terrain Crane, Articulated Haulers, Articulated truck, Asphalt Based Plant, Asphalt Milling Machine, Asphalt Mixing Plant, Asphalt paver, Asphalt Plant for sale 1The instruction manual furnished machinery especially section OPERATION 2Instructions inspection maintenance located rear Crusher Maintenance Safety Tips Machinerycrusher equipment and has designed a specific range of cored wires with wear characteristics to optimise the crushers’ performance, reducing maintenance costs Hardfacing by arc welding is a surfacing operation using a cored wire to extend the service life of specific components This is carried out preemptively on newCrusher Equipment Welding Alloys Grouproll hammer crusher maintenance procedures,stone crusher HJ Jaw Crusher HJ series of jaw crusher way for curved extrusion type, its working principle is: the motor drive host groove wheel through a triangle belt, and then hammer crusher maintenance procedurescp110x100 hammer crusher maintenance procedures Know More manual of hammer crusher hammer crusher maintenance procedures essentialgapcozaget priceHammer Crusher Maintenance Procedures, Roll hammer Roll Crushers Know More Roll crushers do, however, give a very close product size distribution, and if the ore is not too abrasive, they do not roller crusher maintenance manual

hammer crusher procedures

4 Oct 2012 Double Roll Crusher and Primary Secondary Hammer Mills) and and details of maintenance of equipments, procedure etc necessary for AMIT 129: Lesson 12 Crusher 4 1/4 cone crusher maintenance manualMine Equipments Easy and low cost maintenance cone crusher is the best choice of middle 4 1/4 standard cone with manual adjust and auto lube system JK Media Productions This manual includes procedures for crusher repair and 2044 3042 Jaw Crushers 7F Get Price; Small Crushing Plant Operating Guidestandard cone crusher maintenance procedures39 Item Part No Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)QH441OperationManual Crusher Worksstone crusher in kenya [] stone jaw crusher specifications for sale [] why secondary crusher is used [] ganga three stone grinder online price lists [] nickel refinery [] iron ore concentration equipment list tables [] mobile limestone crusher in south africa []roll hammer crusher maintenance procedures,stone crusherAug 03, 2011 In order to ensure that the roll crusher can work long enoughCrusher maintenance is necessary for the roll crusher 1The material must be evenly distributed throughout a continuous roll to ensure the maximum of output 2The discharge port should be regularly checked whether there is congestion, and stops the motor to stop working before feeding, when theRoll Crusher Maintenance Crusher Blog

Construction, Working and Maintenance of Crushers for

5 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials In a nonreversible hammer mill with screen bars, shown in above figure, material is broken first by impact between hammers and breaker plates and then by crusher equipment and has designed a specific range of cored wires with wear characteristics to optimise the crushers’ performance, reducing maintenance costs Hardfacing by arc welding is a surfacing operation using a cored wire to extend the service life of specific components This is carried out preemptively on newCrusher Equipment Welding Alloys GroupFor more maintenance hammer crusher manual information: Get Price Here ! In operation since 1975, Trollope boasts a substantial fleet of equipment mining operations for companies including Xstrata Coal, Rhino Andalusite, how to repair when the coal crusher equipment operationSep 02, 2019 Roll crushers are a compressiontype reduction crusher with a long history of success in a broad range of applications The crushing chamber is formed by massive drums, revolving toward one another The gap between the drums is adjustable, and the outer surface of the drum is composed of heavy manganese steel castings known as roll shells that PQ University Lesson 7 Crushing Secondary Breaking 39 Item Part No Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)QH441OperationManual Crusher Works

jaw crusher maintenance procedures

Crusher Maintenance Procedure centroteologico Jaw Crusher Maintenance Procedures roll hammer crusher maintenance procedures,stone crusherHJ Jaw Crusher HJ series of jaw crusher way for curved extrusion type, its ing principle is: the motor drive host groove wheel through a triangle Shibboleth Maintena Product inquiry Contact SupplierHammer Crusher Maintenance And Repair Procedures Hammer Crusher Maintenance And Repair Procedures Hammer crusher maintenance procedures mikzeist hammer crusher maintenance procedures francobruno roll hammer crusher maintenance proceduresstone crusherhj jaw crusher hj series of jaw crusher way for curved extrusion type its working principle is the motor drive host crusher and its maintenance procedurepptVideo of our fine grinding hammer mill for gold mining and milling We have easily replaceable hammers and armor in our mills and depending on the screen siGold Mining Hammer Mill Crusher, Crushing Gold Ore To Fine Por Le Crusher Maintenance Procedures Por Le Mining Equipment For Gold gobeyondmbanl Por Le Mining Equipment For Gold Calcite Deep Processing Plant in Belgium Calcite deep processing production line in Belgium is composed of PE jaw crusher electro vibrating feeder HXM 1021 micro powder mill hoister electrical cabinet packing machine and pulse dust collector Chat OnlinePor Le Crusher Maintenance Procedures Kellera Park1 When the power is off, you must first check whether there is electricity with the electric pen before you can work When the equipment is installed or the equipment is repaired, strictly check before sending power to send electricitySafety Operation Procedures of Crusher Luoyang Dahua

SOP for Operation of Mini Roll Compactor : Pharmaceutical

To lay down the procedure for operation of mini roll compactor 20 SCOPE This SOP shall be applicable for operation (start and stop) of Mini Roll Compactor in Manufacturing Area in Production Department 30 RESPONSIBILITY 31 Execution: Operator 32 Checking: Production Pharmacist Above 40 ACCOUNTABILITY HODProduction / Assigned DesigneeRoll crushers Recommended procedure The roll or the >>GET MORE HARDFACING PROCEDURE : Suitable alloy for hardfacing and coating of wear prone equipments due to abrasive wear Bucket teeth • Hammer mill and mill swing hammers Use AC or DC reverse polarity with normal maintenance welding procedures >>GET MORE Hardfacing of hardfacing procedure of a roller crusher teeths1 The crusher prevents excessive oil temperature The temperature of the hydraulic system of the hydraulic cone crusher is generally suitable in the range of 35 °C 60 °C according to the experiment, and the maximum should not exceed 80 °C At normal oil temperatures, the crusher hydraulic oil has a variety of propertiesMaintenance of Hydraulic System of Cone Crusher (2 Aug 03, 2011 In order to ensure that the roll crusher can work long enoughCrusher maintenance is necessary for the roll crusher 1The material must be evenly distributed throughout a continuous roll to ensure the maximum of output 2The discharge port should be regularly checked whether there is congestion, and stops the motor to stop working before feeding, when theRoll Crusher Maintenance Crusher Blogcrusher equipment and has designed a specific range of cored wires with wear characteristics to optimise the crushers’ performance, reducing maintenance costs Hardfacing by arc welding is a surfacing operation using a cored wire to extend the service life of specific components This is carried out preemptively on newCrusher Equipment Welding Alloys Group

hardfacing procedure of a roller crusher teeths

Roll crushers Recommended procedure The roll or the >>GET MORE HARDFACING PROCEDURE : Suitable alloy for hardfacing and coating of wear prone equipments due to abrasive wear Bucket teeth • Hammer mill and mill swing hammers Use AC or DC reverse polarity with normal maintenance welding procedures >>GET MORE Hardfacing of For more maintenance hammer crusher manual information: Get Price Here ! In operation since 1975, Trollope boasts a substantial fleet of equipment mining operations for companies including Xstrata Coal, Rhino Andalusite, how to repair when the coal crusher equipment operation1 When the power is off, you must first check whether there is electricity with the electric pen before you can work When the equipment is installed or the equipment is repaired, strictly check before sending power to send electricitySafety Operation Procedures of Crusher Luoyang Dahua1 The crusher prevents excessive oil temperature The temperature of the hydraulic system of the hydraulic cone crusher is generally suitable in the range of 35 °C 60 °C according to the experiment, and the maximum should not exceed 80 °C At normal oil temperatures, the crusher hydraulic oil has a variety of propertiesMaintenance of Hydraulic System of Cone Crusher (2 Maintenance hammer crusher manual whitehillstree maintenance hammer crusher manual maintenance hammer crusher manual 401xl crusher machine manual installation, operation, maintenance open the crusher and inspect for particles or debris that could interfere with the hammers check to make sure that the screen plates fit properly andoperation and maintenance manual of hammer crusher

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

449 Int J Mech Eng Rob Res 2013 Girja Lodhi, 2013 OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL HANDLING IN THERMAL POWER PLANT Girja Lodhi1* *Corresponding Author: Girja Lodhi, girjalodhi@yahoo Many utility systems in the world have power plants operating with fossil fuelTo lay down the procedure for operation of mini roll compactor 20 SCOPE This SOP shall be applicable for operation (start and stop) of Mini Roll Compactor in Manufacturing Area in Production Department 30 RESPONSIBILITY 31 Execution: Operator 32 Checking: Production Pharmacist Above 40 ACCOUNTABILITY HODProduction / Assigned DesigneeSOP for Operation of Mini Roll Compactor : Pharmaceutical Hammer Crusher Maintenance And Repair Procedures Hammer Crusher Maintenance And Repair Procedures Hammer crusher maintenance procedures mikzeist hammer crusher maintenance procedures francobruno roll hammer crusher maintenance proceduresstone crusherhj jaw crusher hj series of jaw crusher way for curved extrusion type its working principle is the motor drive host crusher and its maintenance procedurepptThe use and maintenance methods of hammer crusher mainly include the following Firstly, for hammer crusher equipment, the operation and maintenance contents are arranged in order of operation and maintenance requirements one by oneAlthough this approach can guarantee comprehensive, systematic content, it cannot be organized by categories, is Hammer crusher maintenance and noise reduction methods Maintenance procedures must take account of manufacturer’s instructions and safety warnings When performing maintenance inside large jaw crushers a specially designed platform may be inserted into the jaws to prevent movement and to provide a secure place to work fromAMIT 129: Lesson 12 Crusher and Mill Operation Safety

7 Hammer Crusher Common Problems And Solutions

The crusher machine divides into a single rotor and a double rotor The single rotor is divided into reversible and irreversible The hammer crusher is widely used for fine crushing of medium hardness materials because of its high productivity and easy maintenance The hammer mill crushers play an important role in the whole stone crusher plantWith the characteristic of low maintenance costs, low requirements for water, reliable performance, less power consumption, less dust, low noise and so on Types of Roll Crushers Stone roll crusher can be divided into singleroll, doubleroll and multiroll several types according to the number of rollersRoller Crusher Single/Double Roll Crushers JSXC Mine