Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

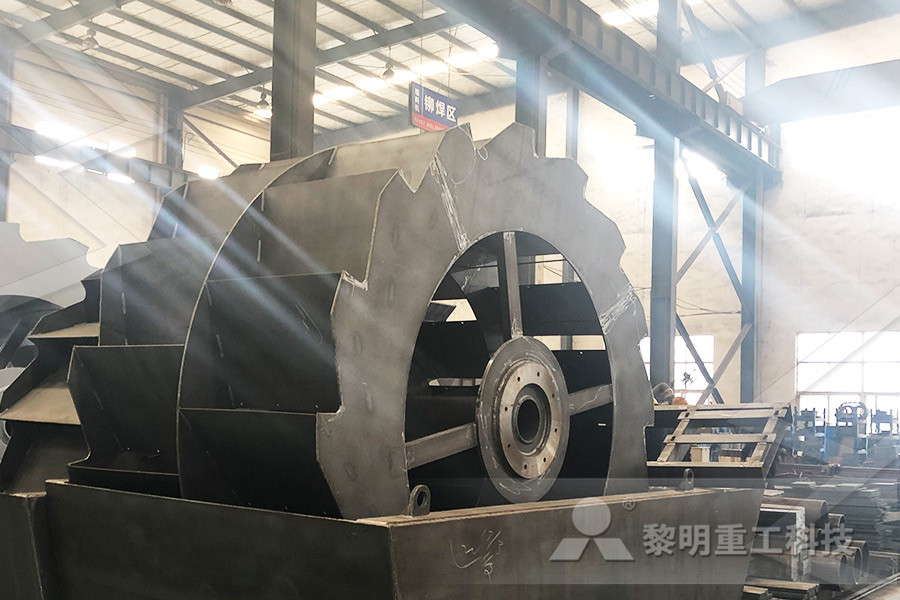

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Flotation Machines Mineral Processing Machine

The flotation machine is composed of single or multiple flotation cells, by agitating and inflating the chemical reagent treated slurry, some mineral ore particles are adhered to the foam and float up, and then be scraped out, while the rest remains in the slurry Types of flotation machineTypically three different types of chemicals are used in the froth flotation process: collector, frother, and modifier First, the collector is added to the iron ore slurry to selectively coat the iron oxide particles, making the surface hydrophobicFlotation Process an overview ScienceDirect TopicsConventional mechanically agitated flotation machines use relatively shallow rectangular tanks, whereas column cells are usually tall vessels with heights normally varying from 7 to 16 m as per requirementFlotation Circuit an overview ScienceDirect TopicsMar 01, 2019 The FloteTech, the first standalone machine to support flotation, was invented by RJ Dausman in the late 1980s Microflotation, which uses glass beakers and magnetic stirrers for gentler processing, was developed in the 1960s for use by various chemists but not extensively used by archaeologists until the 21st centuryFlotation Method in Archaeology ThoughtCoFlotation is commonly used to treat fine coal (typically below 500 microns in size) and is a complex, threephase process that is controlled by factors which can be DESIGN AND PERFORMANCE ASPECTS OF COAL FLOTATION

Flotation technology For coarse and Fine particle recovery

the first type of sizespecific flotation machine that will be described is the hydroFloat®, a machine that was patented by eriez in 2002 by mass was approximately 1000 microns and typically assayed at 04 to 06% copper as has been observed elsewhere, about 10%➤Standard flotation machines (standard energy input, rotor speed (r/min), rotor size/type) at the beginning of the row, where flotation is typically frothphase limited and operational and setup parameters have a limited influence on the recoveryHybrid Energy Flotation on the optimization of fine and The froth Sotation process is commonly employed for the selective separation of a mineral species from a liquid}solid suspension of both valuable andunwantedganguemineral particlesThe valuable mineral species (which needs to be separated) is rendered hydrophobic by controlling its surface chemistry to provide the potential conditions for the attachment of the particles to air bubblesFlotation Cell Design: Application of Fundamental PrinciplesThe value of genuine WEMCO selfaspirated flotation wear parts goes beyond supplying parts that just ‘fit’ your machine Maximum machine availability and reliability, minimum operating costs, and maximum productivity are far more valuable than saving money on the cost of spare partsWEMCO Selfaspirated flotation cells wear parts Nov 01, 2011 Standard flotation machines (energy, rpm, rotor size) at the beginning of the row, whereflotation is froth phase limited and operational and set Mineral Flotation

ElectrocoagulationElectroflotation (ECF) لیان تدبیر

Mar 24, 2020 The electrocoagulation flotation machine is widely used in the wastewater treatment in textile printing, dye chemicals, medical, leather and electroplating industriesthe first type of sizespecific flotation machine that will be described is the hydroFloat®, a machine that was patented by eriez in 2002 by mass was approximately 1000 microns and typically assayed at 04 to 06% copper as has been observed elsewhere, about 10%Flotation technology For coarse and Fine particle recoveryThe flotation machine IF9S is a onecell machine designed for mineral processing by flotation It is mainly used in a grinding cycle for flotation of pulp with a high concentration of solid parts, up to 800 g/dm3, with a high thick grains fraction and for conducting flotation process in a short timeFLOTATION MACHINES śląskie➤Standard flotation machines (standard energy input, rotor speed (r/min), rotor size/type) at the beginning of the row, where flotation is typically frothphase limited and operational and setup parameters have a limited influence on the recoveryHybrid Energy Flotation on the optimization of fine and Flotation deinking is a key unit operation in most paper recycling plants for the removal of hydrophobic contaminants from pulp There is a wide variety of flotation cells available for deinking but the dominant technology typically consists of multiple horizontal flotation cells in series, with each cell being aerated by several injectorsFlotation Column: A Process Unit for Cleaning Up Paper

Jameson cell Wikipedia

Froth flotation is achieved by mixing chemicals known as collectors with the ore slurry The collectors adsorb onto the surfaces of the particles of select minerals (usually the valuable mineral that is targeted for concentration), making these minerals hydrophobic Air is passed through the slurry in a tank known as a flotation cell91 TECHNICAL NOTES 9 FLOTATION Flotation is the most widely used mineral separation method It is the preferred method of mineral recovery for many of the most important minerals that are recovered and large tonnages of ore are processed by flotation annuallyTECHNICAL NOTES 9 FLOTATION Mineral TechThree major sample types are typically chosen Samples are selected for initial reagent definition to achieve the desired mineral separation For a testwork laboratory treating a wide variety of ores, the most useful laboratory flotation machine is probably one INTERPRETATION OF FLOTATION DATA FOR THE DESIGN OF Type:flotation machine Applied Materials: Quartz, gold, silver, copper and iron ore etc nonferrous metals, ferrous metals, coal, fluorite, talc, lead, zincHow Flotation Machine works, flotation machine, ore Solids subject to being separated by froth flotation machines are typically highly abrasive and corrosive As a consequence, frequent replacement of the impeller and diffuser, the components most susceptible to corrosion and the abrasive action of the solid particles, has been a constant and expensive disadvantage of froth flotation machines Flotation machines and components thereof DALTON; ROBERT W

Flotation cell technology and circuit J design—an Anglo

➤Pre 1980s—Mineral extraction circuits were charac terized by multiple small flotation machines (typically 1m3) with short residence times, employing a single millfloat configuration Typically a threestage crushing, closed circuit ball mill comminution circuit was used to prepare feed for flotationJul 27, 2015 Flotation 1 Perth Brisbane Melbourne Noosa L 6, 524 Hay St Perth WA 6000 P: (+61 8) 9421 9000 PO Box 5778 St Georges Tce WA 6831 U 4,14 Merivale St South Brisbane QLD 4101 P: (+61 7) 3029 6220 117 Miller St Thornbury VIC 3071 P: (+61 3) 9495 2666 ABN 66 009 357 171 E: info@metsengineering W: metsengineering Presented by Peter Steckis Consulting Flotation SlideShareNov 01, 2011 Standard flotation machines (energy, rpm, rotor size) at the beginning of the row, whereflotation is froth phase limited and operational and set Mineral Flotation Flotation machine types vary widely also, but are all very similar, in that they introduce air underwater, and disperse it into the cell Some use blowers, air compressors, or the action of the flotation impeller creating a void beneath it and drawing air into the machine, via How Froth Flotation WorksFroth flotation is a process for selectively separating hydrophobic materials from hydrophilicThis is used in mineral processing, paper recycling and wastewater treatment industries Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th centuryFroth flotation Wikipedia

Hydrodynamic Characterization of Industrial Flotation

12 Relevance to industrial flotation machines Industrial flotation cells need to accomplish several functions such as: air bubble dispersion, solid suspension as well as to provide the best conditions for bubbleparticle collision, aggregate formation and froth transport For this reason, cells are typicallyFlotation deinking is a key unit operation in most paper recycling plants for the removal of hydrophobic contaminants from pulp [12] There is a wide variety of flotation cells available for deinking but the dominant technology typically consists of multiple horizontal flotation cells in series, with each cell being aerated by several injectorsFlotation Column: A Process Unit for Cleaning Up Paper flotation pulp as a ruleofthumb, a mean residence time of about 4 minutes or so is typically required in conventional flotation machines to achieve good recoveries of bituminous coals the required residence time may be even longer for difficulttofloat coals that are very fine or oxidizedStackcelltM Flotation a new technology For Fine coal The high intensity of the Jameson Cell means that it is much shorter than conventional column flotation cells (see Figure 1), and it does not require air compressors to aerate the suspension of ground ore particles and water (known as a slurry or pulp) in the flotation cell The lack of a requirement for compressed air and the lack of moving parts means that power consumption is less than for Jameson cell WikipediaJul 18, 2013 Flotation works very well for particles that are typically in the range 20 to 150 μm in diameter, for base metal ores In this range, it is possible to obtain quite high recoveries in conventional flotation machines Outside this range, the recoveries decline progressively, whether it is with the very fine or thecoarse end of the size spectrumAdvances in Fine and Coarse Particle Flotation: Canadian

Flotation SlideShare

Jul 27, 2015 Flotation 1 Perth Brisbane Melbourne Noosa L 6, 524 Hay St Perth WA 6000 P: (+61 8) 9421 9000 PO Box 5778 St Georges Tce WA 6831 U 4,14 Merivale St South Brisbane QLD 4101 P: (+61 7) 3029 6220 117 Miller St Thornbury VIC 3071 P: (+61 3) 9495 2666 ABN 66 009 357 171 E: info@metsengineering W: metsengineering Presented by Peter Steckis Consulting Three major sample types are typically chosen Samples are selected for initial reagent definition to achieve the desired mineral separation For a testwork laboratory treating a wide variety of ores, the most useful laboratory flotation machine is probably one INTERPRETATION OF FLOTATION DATA FOR THE DESIGN USA US07/957,112 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords flotation alkoxylated guanidine alkyl amine Prior art date Legal status (The legal status is an assumption and is not a legal conclusionUSA Flotation process for purifying calcite the flotation of iron ore, phosphate and coal Flotation columns differ dramatically from mechanical flotation machines in several ways: • there is no mechanical agitation/shear • the cell is relatively tall and narrow • gas bubbles are generated by sparging • froths typically are deeper, and wash water typically is liberally applied Column Flotation SGSNov 27, 2017 The RCS flotation machine is the latest design to use the circular tank concept and combines the benefits of circular cells with the unique features of the mechanism to create the ideal conditions to maximise flotation performance for all roughing, cleaning and scavenging duties Flotation circuit control is typically based on regular on Barry Wills' Blog: Flotation '17 Conference Diary

Flotation Costs Overview, Factors, and Cost of Capital

The flotation costs for the issuance of common shares typically ranges from 2% to 8% Flotation Costs and Cost of Capital The concept of flotation costs is strongly related to the concept of cost of capital Cost of Capital Cost of capital is the minimum rate of return that a business must earn before generating value