Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

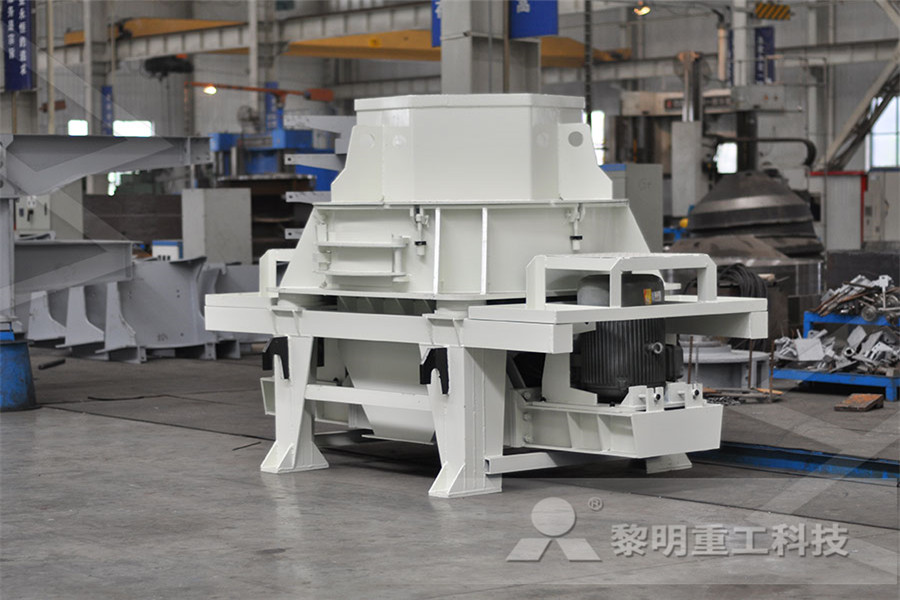

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Gold CIP Processing,Gold CIP Plant,Gold CIP Production

CIP (Carbon in pulp) process is a high efficient method to leaching and recovering gold from gold ore, The most different from CIL process is in CIP process, gold leaching and adsorption are separated, first leaching, and then adsorption Now it is being replacing by CIL process progressively But it still have a lot of applicationGold CIL CIP Gold Leaching Process Explained CCD CIL stands for carboninleach This is a gold extraction process called cyanidation where carbon is added to the leach tanks (or reaction vessel) so that leaching and adsorption take place in the same tankscip in gold processing Gold CIP system is a useful gold recovery method in mineral processingCip System, Cip Process, Cip Gold Processing XinhaiHaycarb has been a pioneering supplier of activated carbon for Carbon in Pulp (CIP), Carbonin leach (CIL) and Carbonincircuit (CIC) processes in gold mining since the 1970sCIP /CIL /CIC gold extraction Haycarb PLCCIP ( Carbon In Pulp) process is suitable for the treatment of oxidized gold ore with low sulfur content and mud contentIt is unsuitable for the gold ore with highgrade silver as well Generally, the proportion of gold and silver should not exceed 1:5 The best conditions for Carbon In Pulp process in China: PH=1012, sodium cyanide concentration is not less than 0015%, the particle size of Carbon in Pulp Gold CIP JXSC Machine

Cip System, Cip Process, Cip Gold Processing Xinhai

Gold CIP process adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp Gold CIP system is a useful gold recovery method in mineral processingCIP /CIL /CIC gold RPMC 1003 RPMC 1032 RPMC 1033 RPMC 1034 Haycarb has been a pioneering supplier of activated carbon for Carbon in Pulp (CIP), Carbonin leach (CIL) and Carbonincircuit (CIC) processes in gold mining since the 1970s Recognizing the critical role activated carbon plays in a gold mining process, Haycarb Gold Activated Carbon CIP /CIL /CIC gold extraction Haycarb PLCAug 14, 2019 Difference between CIL and CIP: * CIL is adsorbed while leaching; * CIP is first leached and adsorbed 1 CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushedWhat is the difference between CIP and CIL gold leaching The carbon in pulp (CIP) and carbon in leach (CIL) processes became firmly established in the gold mining industry in the 1980s, initially in South Africa and Australia, from where they spread (PDF) Gold CIP and CIL process optimization in a capital Zinc Ore Mining Cip Gold Recovery New Our company mainly produces five series of products, including crushing equipment, sand making equipment, mineral processing equipment, grinding equipment and building materials equipment 40 years of mining machinery manufacturing history, three production bases, exported to more than 160 countries and regions, We are your trusted partner and Zinc Ore Mining Cip Gold Recovery New

The process design of gold leaching and carboninpulp

The process design of gold leaching and carboninpulp circuits 14 JANUARY/FEBRUARY 1999 The Journal of The South African Institute of Mining and Metallurgy Figure 2—The CarbonInPulp (CIP) process Figure 1—ComputerAided Process Engineering (Cape)Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 97%Gold CIL Production Line,Gold CIL Process,Gold CIL Plant Dec 16, 2020 The autoclaves operate at 1,725kPa pressure and 197°C, producing feed for the leaching and CIP circuits Combined leach and CIP recovery is 90–95% of the contained gold In 1999, a floatation expansion was installed and additional oxygen capacity was added to Placer Dome Gold Mine Mining Technology Mining News 911MPE has small gold mining equipment for sale and more specifically mineral processing equipmentOur equipment is best used in small scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics 911MPE’ offers gold mining equipment as well as processing equipment applicable to most any base metals: copper, lead, zinc, nickel, tin, tungsten and Gold Mining Equipment 911MetallurgistAlibaba offers 1,719 gold cip production line products A wide variety of gold cip production line options are available to you, such as local service location, key selling points, and applicable industriesgold cip production line, gold cip production line

Mponeng Gold Mine, Gauteng Mining Technology Mining

Ore mined is treated and smelted at Mponeng’s gold plant The ore is initially ground down by means of semiautogenous milling after which a conventional gold leach process incorporating liquid oxygen injection is applied The gold is then extracted by means of carboninpulp (CIP) technologyGold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design With the rising gold prices in recent years, it further stimulated the rapid development of gold industry As the exhaustion of highgrade gold ore, researching on middlelow grade and refractory gold ore and strengthen the traditional gold mining process undoubtedly have become the main trend in global gold beneficiation industryGold Mining Process, Gold Recovery Process, Gold Cyanide CIP ( Carbon In Pulp) process is suitable for the treatment of oxidized gold ore with low sulfur content and mud contentIt is unsuitable for the gold ore with highgrade silver as well Generally, the proportion of gold and silver should not exceed 1:5 The best conditions for Carbon In Pulp process in China: PH=1012, sodium cyanide concentration is not less than 0015%, the particle size of Carbon in Pulp Gold CIP JXSC MachineThe carbon in pulp (CIP) and carbon in leach (CIL) processes became firmly established in the gold mining industry in the 1980s, initially in South Africa and Australia, from where they spread (PDF) Gold CIP and CIL process optimization in a capital

New technology to tackle human costs of illegal gold mining

Dec 17, 2020 Wake Forest faculty in the University’s Center for Energy, Environment and Sustainability, and its Center for Amazonian Scientific Innovation (CINCIA) are part of an awardwinning research team working to provide new technology to government regulators and local communities in the Amazon that could help eliminate the environmental and human costs of illegal gold miningThe APT TriTank is available as a small scale CIP/CIL cyanidation plant The TriTank takes on a whole new revolutionary design making for a more environmentally conscious and even better way of using cyanidation as a gold extraction process, even at such a small scale The design has multiple benefiSmall Scale CIP/CIL Cyanidation Plant APT TriTank The CIP process is the single adsorption, the complementary quantity of dissolved gold in the solution is very small, so the gold grade is lower Conclusion The above are the differences between gold CIP and gold CIL processIn actual production, it is best to consult with professional manufacturers and choose the right gold processing methodWhat Are the Differences Between CIP and CIL? MiningpediaToday’s gold mining operations optimize efficiency and output through the use of superior Haycarb gold recovery carbon technology Our high density carbons with particle to particle consistency in activity and shape is an ideal solution for applications in CIL (carboninleach), CIP (Carboninpulp) and CIC (carbonincolumn) processesActivated Carbon In Absorption Gold Extraction Haycarb PLCAlibaba offers 1,719 gold cip production line products A wide variety of gold cip production line options are available to you, such as local service location, key selling points, and applicable industriesgold cip production line, gold cip production line

Gold Processing,Extraction,Smelting Plant Design

Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designs