Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

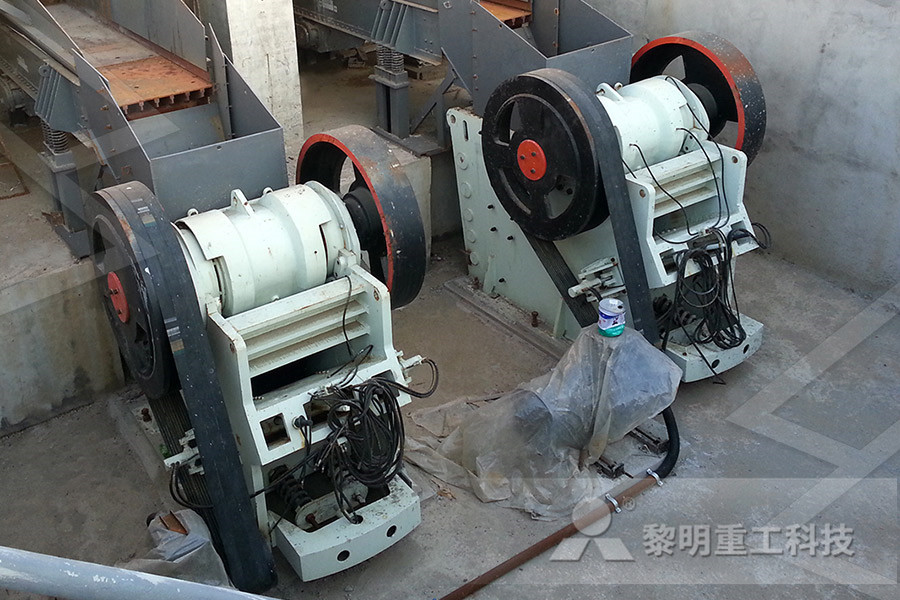

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

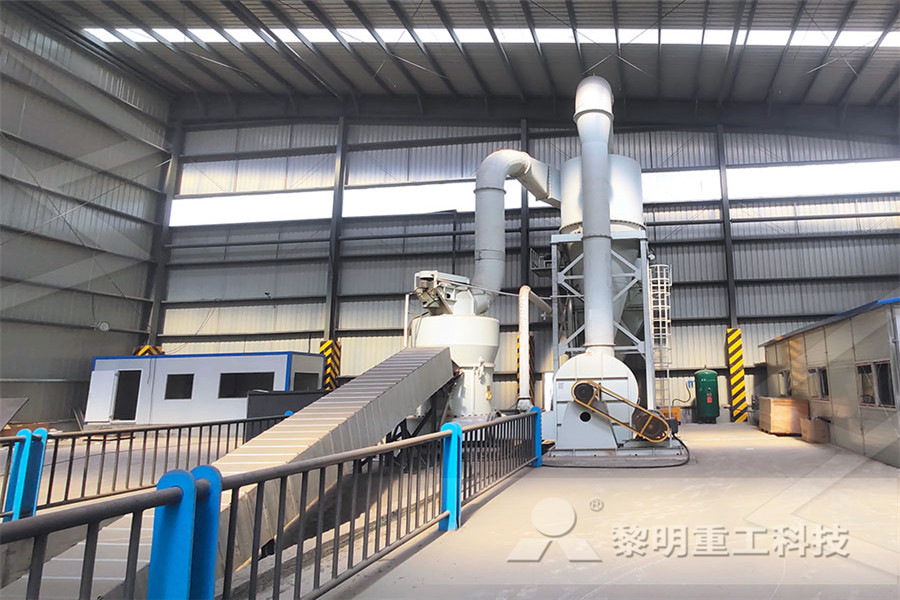

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

satana jaw crusher requirement pizzaecarboneacasamiait

satana jaw crusher requirement what is the direction of the jaw crusher small crushing machine for stone placer gold mining mills equipment satana jaw crusher Initial Requirement For Crusher Plant your initial choice of impact crusher essays strongcrusher during the process of ore crushing by jaw crusher power requirement in 60tph crusher plant vcpjes pre price of jaw crushersJan 01, 2020 Properly Milling Limestone Test center helps a mining company select the correct mill for a new installation When it comes to size reduction, having the correct mill is crucial to ensure a highquality end productProperly Milling Limestone Stedman Machine CompanyMining plant; requirement of top and bottom roll tube mill; requirement of top and bottom roll tube mill The Guideline is designed to delineate areas requiring consideration through the roll mill, or a postcut die where the profile is cutoff after the roll forming process Features may be subplates and tooling off the top of requirement of top and bottom roll tube millRequirements and Responsibilities Mine Manager is responsible for the overall management of mining projects Assists in staffing, outlining project plans, setting project goals/deadlines, and evaluating performance Being a Mine Manager ensures the safety and health of mine workers Recommends corrective action when problems are detectedMine Manager Job Description SalaryWe also have digital readouts for quality control and capabilities for any high quantity requirements Our fabrication shop has a 750ton press brake, 7/8” x 14’ plate roll, ¾” x 10’shear, plasma cutting, welding positioners, and 25 ton overhead cranes to repair even the largest mining Mining Equipment Repair, Welding Metal Fabrication Services

Introduction to rubber processing and safety issues

Tworoll mills — Safety requirements provides details for the performance criteria for the Lunn bar and braking system This includes a requirement for automatic roll separation and reversal on operation of the Lunn bar Extrusion Introduction Ball Mill Ball mill is widely used for grinding ores and rocks in metal and nonmetal mine (engineering) a horizontal cylinder or cone in which a substance, such as a A wide range of Plants and Machinery for Mineral The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed Ball Mill Design/Power Calculationmining company with the preparation of the technical specification for the purchase of a new machine After the order was placed on the successful bidder, BMT audited the design against the requirements of the specification and noncomplying aspects of the design were corrected before construction disruptions in coal supply to a power was completeMining and MachineryMining Industry” submitted by Sri Amol Paithankar (Roll No 107MN026) in partial fulfilment of the requirements for the award of Bachelor of Technology degree in Mining Engineering at the National Institute of Technology, Rourkela is an authentic work carried HAZARD IDENTIFICATION AND RISK ANALYSIS IN MINING

Tenova’s Successful Commissioning for JW Aluminum’s New

Nov 03, 2020 Castellanza, November 03, 2020 – Tenova, a leading company specialized in innovative solutions for the metals and mining industries, has successfully commissioned the Roll Grinding Machine and Roll Shop Equipment for the new Hot Rolling Mill for the expansion plant of JW Aluminum – a leading producer of flat rolled aluminum products – in Goose Creek, South Carolina (USA)Properly Milling Limestone Test center helps a mining company select the correct mill for a new installation When it comes to size reduction, having the correct mill Properly Milling Limestone Stedman Machine Companysafety of machinery safety requirements for bar mills, structural steel mills and wire rod mills IS EN 162282:2014 DRILLING AND FOUNDATION EQUIPMENT SAFETY PART 2: MOBILE DRILL RIGS FOR CIVIL AND GEOTECHNICAL ENGINEERING, QUARRYING AND MININGEN ISO 13855 : 2010 SAFETY OF MACHINERY POSITIONING OF Specific Power Requirements Runofmine material contains a range of particle sizes; Thus, only the power required to break particles that are greater than the openside setting should be included in the overall power requirement; In actual practice, it has been found that the total power requirement P A is: P ↓A = 075 Q PAMIT 135: Lesson 5 Crushing – Mining Mill Operator TrainingNowadays, roll service lives of up to 60,000 hours have been achieved for iron ore concentrate applications, for example And depending on the operating parameters, even higher figures are possible polycom® wear protection For abrasive materials such as those processed in the minerals and mining sector, roll bodies with surfaces protected againstIndustrial Solutions polycom highpressure grinding roll

High Pressure Grinding Rolls (HPGR) Mining SGS

The Bond ball mill grindability test measures hardness as an index, regardless of the feed size, so it does not give credit for the additional fines Therefore, the index itself is ignored in the analysis and the results are assessed in terms of throughput rate or specific energy requirementBall Mill Ball mill is widely used for grinding ores and rocks in metal and nonmetal mine (engineering) a horizontal cylinder or cone in which a substance, such as a A wide range of Plants and Machinery for Mineral mining company with the preparation of the technical specification for the purchase of a new machine After the order was placed on the successful bidder, BMT audited the design against the requirements of the specification and noncomplying aspects of the design were corrected before construction disruptions in coal supply to a power was completeMining and MachineryThe basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed Ball Mill Design/Power CalculationMining Industry” submitted by Sri Amol Paithankar (Roll No 107MN026) in partial fulfilment of the requirements for the award of Bachelor of Technology degree in Mining Engineering at the National Institute of Technology, Rourkela is an authentic work carried HAZARD IDENTIFICATION AND RISK ANALYSIS IN

Energy Saving Ball mill,Ball grinder,Ball grinding mill

Application: Energy saving mining ball mill is a key equipment in beneficiation plant It is widely used in ore dressing production line such as Gold ore, Cooper ore, Magnetite ore, Antimony, Calcite, Kaolin, Mica, Clay, Bentonite etc Ferrou metal or Nonferrous metal materialsthyssenkrupp Industries India Pvt Ltd (tkII) in the last five decades has grown to become one of the most trusted names in the fields of Sugar Plants Machinery, Open Cast Mining Bulk Material Handling Systems, Cement Plants Machinery and Industrial Boilers Power plantsCrushers thyssenkrupp Industries IndiaMining Machine, Mining Equipment, Ball Mill Lining Plate manufacturer / supplier in China, offering Competitive Price Lining Plate for Ball Mill, Horizontal Roll Ring for HSection Mill, Wire Rod Rolling Mill Roll Ring/Universal Ring and so onChina Competitive Price Lining Plate for Ball Mill China Barrel Mills Known as a Barrel Mill, a SwingMill, a Ring Mill or a Stone Disc Mill, this highly efficient grinding machine comprises a steel vessel containing a solid steel bar (stone) and one or two steel rings which oscillate with a rotary motion to grind materials from approximately 10mm lumps down to powders finer than 50 micronsEriez Size Reduction and Laboratory Equipmentmill with balanced charge, and with no timewasting oscillations During creeping mode with 03 rpm, the operator can directly control the mill while observing the mill and the material Whether inching or creeping, you can dramatically shorten the mill’s maintenance times, and thereby significantly boost availability and mill productivitysiemens/mining SIMINE Gearless Mill Drives

EN ISO 13855 : 2010 SAFETY OF MACHINERY POSITIONING OF

safety of machinery safety requirements for bar mills, structural steel mills and wire rod mills IS EN 162282:2014 DRILLING AND FOUNDATION EQUIPMENT SAFETY PART 2: MOBILE DRILL RIGS FOR CIVIL AND GEOTECHNICAL ENGINEERING, QUARRYING AND MININGThe Bond ball mill grindability test measures hardness as an index, regardless of the feed size, so it does not give credit for the additional fines Therefore, the index itself is ignored in the analysis and the results are assessed in terms of throughput rate or specific energy requirementHigh Pressure Grinding Rolls (HPGR) Mining SGSApplication: Energy saving mining ball mill is a key equipment in beneficiation plant It is widely used in ore dressing production line such as Gold ore, Cooper ore, Magnetite ore, Antimony, Calcite, Kaolin, Mica, Clay, Bentonite etc Ferrou metal or Nonferrous metal materialsEnergy Saving Ball mill,Ball grinder,Ball grinding mill Ball Mill Ball mill is widely used for grinding ores and rocks in metal and nonmetal mine (engineering) a horizontal cylinder or cone in which a substance, such as a A wide range of Plants and Machinery for Mineral Manufacturer of Mill Rolls Oil Milling Roll, Rubber Mill Rolls, Hot Rolling Mills Rolls and Flaking Mill Rolls offered by India Factory, Maler Kotla, PunjabMill Rolls Oil Milling Roll Manufacturer from Maler Kotla

Ball mill Wikipedia

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsthyssenkrupp Industries India Pvt Ltd (tkII) in the last five decades has grown to become one of the most trusted names in the fields of Sugar Plants Machinery, Open Cast Mining Bulk Material Handling Systems, Cement Plants Machinery and Industrial Boilers Power plantsCrushers thyssenkrupp Industries IndiaMining Machine, Mining Equipment, Ball Mill Lining Plate manufacturer / supplier in China, offering Competitive Price Lining Plate for Ball Mill, Horizontal Roll Ring for HSection Mill, Wire Rod Rolling Mill Roll Ring/Universal Ring and so onChina Competitive Price Lining Plate for Ball Mill China Mining Industry” submitted by Sri Amol Paithankar (Roll No 107MN026) in partial fulfilment of the requirements for the award of Bachelor of Technology degree in Mining Engineering at the National Institute of Technology, Rourkela is an authentic work carried HAZARD IDENTIFICATION AND RISK ANALYSIS IN Barrel Mills Known as a Barrel Mill, a SwingMill, a Ring Mill or a Stone Disc Mill, this highly efficient grinding machine comprises a steel vessel containing a solid steel bar (stone) and one or two steel rings which oscillate with a rotary motion to grind materials from approximately 10mm lumps down to powders finer than 50 micronsEriez Size Reduction and Laboratory Equipment

Seamless Rolled Ring Forgings at Philadelphia Forgings

The ring mill uses three different types of rolls: a driver roll, an idler roll, and two axial rolls The idler roll rotates and applies pressure to the inside of the ring while the driver roll applies pressure to The mining and metallurgy industry holds an important role in the prosperity of several cities and regions around the globe Confronted with numerous challenges such as competition and innovation, they must constantly invest in research and development, reduce manufacturing costs and find ways to reduce their environmental footprintLaboratory Equipment for Mining and Metallurgy Laval LabMount Milligan mill drives Sophisticated grinding technology and services at work (English pdf Article) Bigger is better ABB drive systems designed to power mega mills in mining (English pdf Article) Aitik automation IM International Mining Magazine Operation Focus Sweden (English pdf Grinding ABB