Solutions

Products

-

Primary mobile crushing plant

-

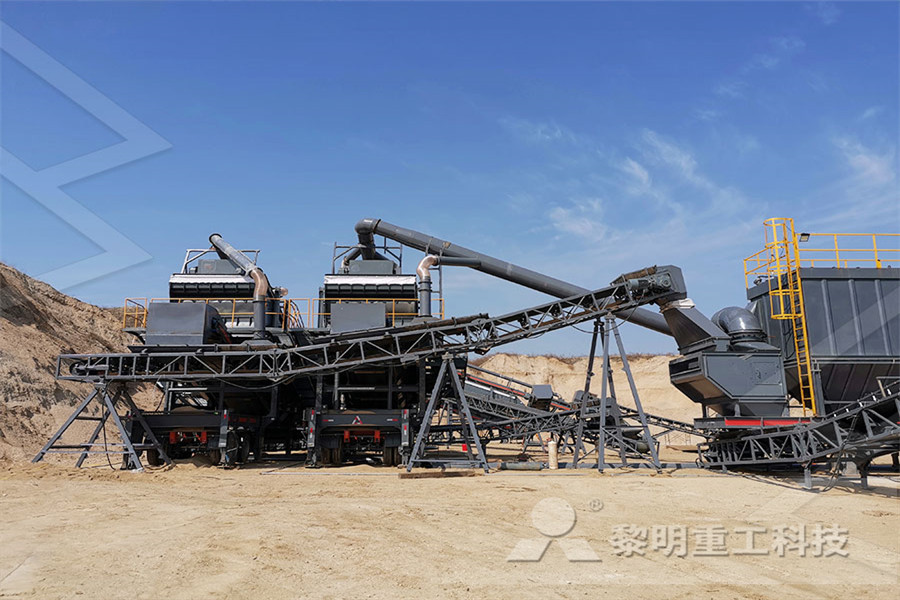

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Anhydrite, synthetic Solvay

Anhydrite is an anhydrous compound it does not contain water in its crystal structure, unlike other minerals Anhydrite is a unique material with outstanding properties beneficial to many industrial applications Applications Floor screed Widely used in floor screed applications and can replace traditional cement as a binder for screed mortarsAnhydrite Anhydrite Liquid Screed is a screeding product that is often chosen over traditional sand and cement screed due to its many advantages Up to 1500m2 of Anhydrite screed can be installed within one day; and since the Liquid Screed cures quickly, there is Anhydrite Liquid Screed Flowing Screed EJS Floor SolutionsHigh Performance Anhydrite Flowing Screed New to Cloburn Granitmix is our latest offering Granitflow Screed Granitflow Screed is the perfect way to get the most out of your underfloor heating system, as the flowability of liquid screed means that it encloses pipework completely, eliminating air bubbles and gaps to ensure improved heat conductivity throughout your floor Even if you don’t GranitFlow Screed Granitmix Anhydrite Flowing ScreedCement and anhydrite – two strong representatives Both binders bond with the process of hydration with water Both are mineral Nevertheless, the difference between them is significant Cement unlike anhydrite is a binder “resistant” to water and negative temperature Cement screeds can be used in wet areas (without any restrictions) and CEMENT OR ANHYDRITE – this is the questionGlobal Gypsum and Anhydrite Market By Type (Natural Gypsum and Anhydrite , and Synthetic Gypsum and Anhydrite), By Application (Prefabricated Products , Plasters , and Portland Cement), By Region, and Key Companies Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 20192028Global Gypsum and Anhydrite Market Segment Outlook, Market

Anhydrite Screeds Anhydrite Floor Screed Liquid Screed Ltd

The gypsum replaces conventional cement as a binder An anhydrite screed is a liquid screed that is poured on to the substrate using a pump This means that anhydrite screeds can be laid very quickly – at Liquid Screeds we can lay 100 square metres in around 45 minutes and as much as 2,000 square metres in CA50 bonded concrete’s lowest stable strength should be determined by the lowest strength of 714 days of demoulding sample curing in 20℃±1℃ water Calcium aluminate Cement Packing: by 50kgs bag Store in shady, cool and dry place Avoid stamp and mix with other substance Where to Buy Calcium Aluminate CementCalcium Aluminate Cement Manufacturer Supplier The bay size with traditional sand cement, should be no more than 40 m2, when you’re working with an of aspect ratio of a 2:1 With the anhydrite screed, for a screed with underfloor heat in it, you are looking at a 300 m2 And without underfloor heating, you are looking at 1,000 m2 Anhydrite Screed Flow Screed Option For Your ProjectAnhydrite, or anhydrous calcium sulfate, is a mineral with the chemical formula CaSO 4It is in the orthorhombic crystal system, with three directions of perfect cleavage parallel to the three planes of symmetryIt is not isomorphous with the orthorhombic barium and strontium sulfates, as might be expected from the chemical formulasDistinctly developed crystals are somewhat rare, the mineral Anhydrite Wikipediabuy now Anhydrite Super® is a synthetic anhydrous calcium sulphate (CaSO4) Stable and finely ground, its main use is indoors as a binder in sulphatebased selflevelling screeds—where it dries more rapidly and gains strength more quickly than cementbased selflevelling screedsCalumex Anhydrite Super® Delta Performance Products

Industrial Filler No 1 USG

A milled anhydrite filler for use in specialty cement applications Contributes to dimensional stability, green strength and controlled set Industrial Filler No 1 is used to develop ettringite in cementitious systems such as specialty cements, grouts and mortarsAnhydrite is a mineral from the Calcium Sulphate family (CaSO4) Anhydrite is an anhydrous compound it does not contain water in its crystal structure, unlike other minerals Anhydrite is a unique material with outstanding properties beneficial to many industrial applicationsCALCIUM SULFATE ANHYDRITE Fine SolvayProduct Description: Product Name:Gypsum Powder MF: CaSO41/2H2O Application: 1 Building materials and buildings A: anhydrite cement and cementing material: adding proper amount of activator can produce anhydrite cement or cementing material, which is suitable for the reinforcement of Bulkbuy Building Plaster Gypsum Powder Pure for Ceramics Anhydrite flow screed: Optimal mixing in the silo The anhydrite flow screed produced by CEMEX Austria is one of the most highgrade types in the world This screed, produced using calcium sulfate, has excellent flow behavior and is therefore ideally suited for eg laying floors with floor heating systemsCEMEX: Austria binding material silo HBMThis report analyzes the worldwide markets for Gypsum and Anhydrite in Thousand Metric Tons by the following enduse segments Prefabricated Products, Plasters, Portland Cement, and Agriculture Global Gypsum and Anhydrite Industry PR Newswire

Global Gypsum and Anhydrite Industry PR Newswire

This report analyzes the worldwide markets for Gypsum and Anhydrite in Thousand Metric Tons by the following EndUse Segments: Prefabricated Products, Plasters, Portland Cement, and Agriculture This compares favourably with cement manufacture, which exerts in the region of 900kg per 1 tonne of material produced You could, therefore, save up to 94% of the carbon emissions associated with the manufacture of your floor screed by switching from cementbased to Gypsol screed Find out more in our carbon footprint guidance sheetGypsol selfsmoothing floor screed Anhydrite binder LKAB Anhydrite screeds are not compatible with cement based adhesives, which is the majority of them The chemicals in the screed (the sulphates) can react with those found in cement (the aluminates) This results in the production of a powder (ettringite) which can critically damage the screed itself, as well as weaken the bond to the floor tile Tips on Anhydrite Screeds and Floor Tiles – Tile DevilTilemaster AnhyFix cannot be used on cement based substrates such as sand/cement screed and concrete Anhydrite/Calcium Sulphate Screeds must be confirmed dry via consistent moisture readings across the area to be tiled Anhydrite/Calcium Sulphate Screeds must be below 85% Relative humidity before tiling can commence As a guide for drying Tilemaster AnhyFix Tile Adhesive Tiling Supplies DirectApr 24, 2015 The influences of aluminum sulfate (AS) introduction and dosage on setting time, hydration heat evolution, hydration product type and pore structure of Portland cement were studied, and the influence of AS on concrete strength was investigated also The results indicate that AS can effectively accelerate setting time of Portland cement and enhance concrete at early age (1 day) Study of aluminum sulfate and anhydrite on cement

Liquid Floor Screed Flowing Screed Suppliers, London

Screedflo Ltd is a specialist in the manufacturer and installation of flowing liquid anhydrite screed, with over 12 years of experience We control the complete process from manufacture to installation, so you can be sure of receiving the highest quality products and excellent serviceWhere anhydrite cement is pervasive and has plugged the rock fabric, poroperm values are significantly decreased As emphasized in previous studies and confirmed here, dolomitization and anhydrite cementation, together with original facies type, are the major factors controlling reservoir quality in the Dalan – Kangan carbonates at South ParsDOLOMITIZATION AND ANHYDRITE PRECIPITATION IN Oct 04, 2013 In all cases whether sand cement, concrete or anhydrite these membranes should NOT be used on screeds with underfloor heating This makes anhydrite very advantageous as you can use the heating to force dry the screed thus removing the need to DPM's It is usually cheaper to force dry than to to DPM anyway** Linked to the last questionInfo on Anhydrite screeds The Flooring Forum Number BUY NOW Anhydrite Super® is a synthetic anhydrous calcium sulphate (CaSO4) Stable and finely ground, its main use is indoors as a binder in sulphatebased selflevelling screeds—where it dries more rapidly and gains strength more quickly than cementbased selflevelling screedsCalumex Anhydrite Super® Delta Performance ProductsA milled anhydrite filler for use in specialty cement applications Contributes to dimensional stability, green strength and controlled set Industrial Filler No 1 is used to develop ettringite in cementitious systems such as specialty cements, grouts and mortarsIndustrial Filler No 1 USG

Gypsol selfsmoothing floor screed Anhydrite binder LKAB

This compares favourably with cement manufacture, which exerts in the region of 900kg per 1 tonne of material produced You could, therefore, save up to 94% of the carbon emissions associated with the manufacture of your floor screed by switching from cementbased to Gypsol screed Find out more in our carbon footprint guidance sheetAnhydrite Screed Depth Thickness/depth of the screed, can dramatically change anhydrite screed cost At 50mm depth which is about the average depth for this particular product, compared with 75mm, that would require 50% more material going into that floor, and increase the anhydrite screed costAnhydrite Screed Cost? Screed Knowledge Centre