Solutions

Products

-

Primary mobile crushing plant

-

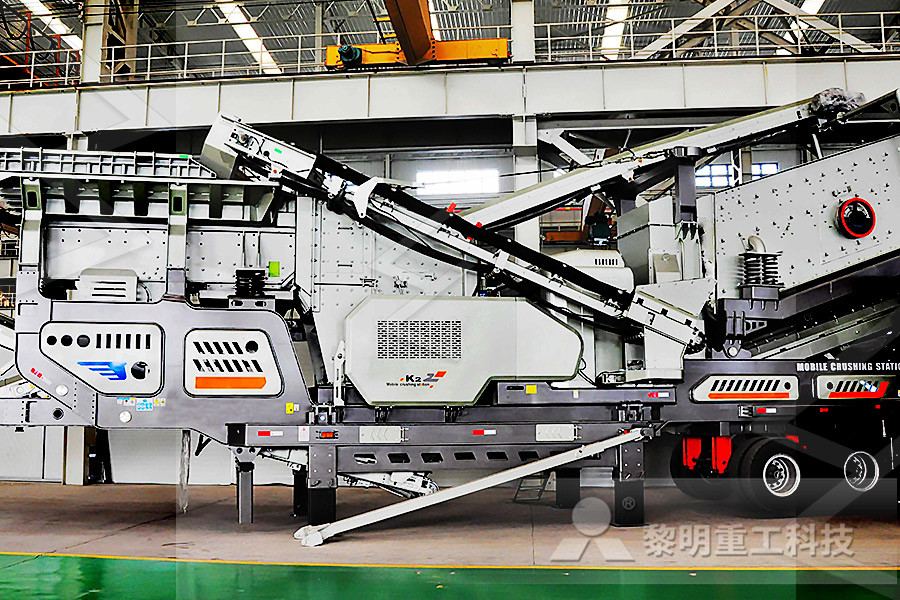

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

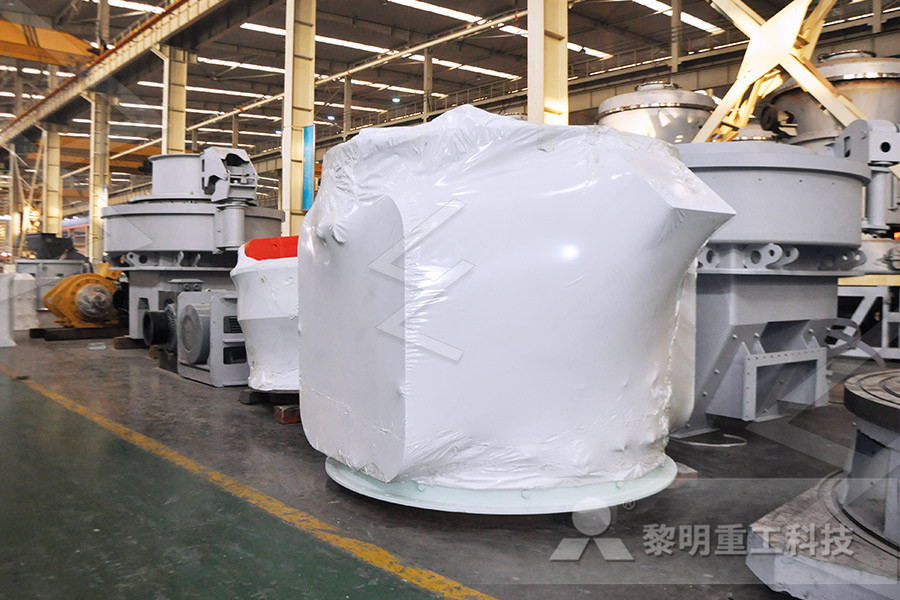

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Bond Rod Mill Work Index Equipment Apparatus Review

Commentary on the apparatus of the Bond rod mill Work Index by Alex Doll December, 2015 alexdoll@sagmilling The Bond “Third Theory” of comminution was originally divided into three size classes reflecting the varieties of comminution equipment common during the time period when Bond Rod mill work index is used in the Bond/Barratt specific energy consumption model The work index is used to calculate the energy requirement to grind rocks in the medium size range, from 10 mm 20 mm down to about 2 mmTestwork: Bond rod mill work index The Rod Mill Work Index (RWI) is used for particle size determination in a size range from 25 mm down to 21 mm whereas Ball Mill Work Index (BWI) is used for the range from 21 mm down to 100 µm Adjustment of grinding parameters:Bond Index Ball Mill / Rod Mill BT 100 XL RETSCHBall mill design requires a Bond work index, BWi, for ball mills at the correct passing size; SAG mill design requires an appropriate SAG test, for example, SPI (Chapter 5) Flotation design needs a valid measure of kinetics for each sample, including the maximum attainable recovery and rate constants for each mineral (Chapter 12)Bond Work Index an overview ScienceDirect TopicsBond Rod Mill Grindability Test Grinding Solutions can carry out Bond Rod Mill Work Index tests to determine the energy requirements for milling ore in a rod mill The test requires a minimum of 20kg of 125mm material Closing screen sizes typically range from 475mm to 212µmBond Work Index Tests Grinding Solutions Ltd

Bond Tests Mining SGS

Bond Rod Mill Grindability Test The test determines the Bond Rod Mill Work Index which is used with Bond’s Third Theory of Comminution to calculate net power requirements when sizing ball mills* Various correction factors may have to be applied The test is a closedcircuit dry grindability test performed in a standard rod millBond Ball Mill Work Index, BWi, kWh/t 134 Bond Rod Mill Work Index, RWi, kWh/t 181 Table 1 Example of AG/SAG Ball Mill Circuit Wio Calculations [1] [2] ABstrAct Optimum use of power in grinding, both in terms of grinding efficiency and use of installed capital, can have a large effect on profitabilityApplication of Operating Work Indices in Autogenous Bond Test WI’s (kWh/t): Rod Mill: Ball Mill: 95 kWh/t8 9 kWh/t Bond Standard Circuit Work Index: Assume the rod mill Work Index of 95 applies from the actual rod mill feed sizeof 19,300 mµ (although some of this work might ideally be done by crushers to achieve a rod mill F80 of 16,000 m) to a rod µGMSG GUIDELINE: DETERMINING THE BOND EFFICIENCY OF The Rod Mill Work Index (RWI) is used for particle size determination in a size range from 25 mm down to 21 mm whereas Ball Mill Work Index (BWI) is used for the range from 21 mm down to 100 µm Adjustment of grinding parameters:Bond Index Ball Mill / Rod Mill BT 100 XL RETSCH(PDF) determination of Bond rodmill work index by modeling the grinding kinetics Mohsen Hashemzadeh Academiaedu Generally, Bond work index is a common method for selecting comminution equipment as well as estimation of grinding efficiency and calculating required power(PDF) determination of Bond rodmill work index by

Bond Work Index Rod Mill Titan Process Equipment Ltd

The Titan Bond Work Index Rod Mill is onepiece cast construction with integral wave liners of a form described by Bond This mill is used to perform the necessary metallurgical testing to determine the grinding characteristics of ores and power requirements for operating productionsize rod mills(PDF) determination of Bond rodmill work index by modeling the grinding kinetics Stefano Ordoiza Campanella Academiaedu Generally, Bond work index is a common method for selecting comminution equipment as well as estimation of grinding efficiency and calculating required power(PDF) determination of Bond rodmill work index by Bond Work Index for Rod Mill Product Image Introduction The Bond Work Index for Ball Mill is a special equipment for testing Bond ball mill work index Simple lab test can choose ball mill by power method or judge the effects of material properties change to the ball milling process or the operation condition of crusher by using this China Bond Work Index for Rod Mill Manufacturers and SuppliersBond Rod Mill Grindability Test Grinding Solutions can carry out Bond Rod Mill Work Index tests to determine the energy requirements for milling ore in a rod mill The test requires a minimum of 20kg of 125mm material Closing screen sizes typically range from 475mm to 212µmBond Work Index Tests Grinding Solutions LtdThe Bond ball mill work index is one of the most commonly used grindability tests in mining, and is often referred to as the Bond work index The test is a 'lockedcycle' test where ground product is removed from test cycles and replaced by fresh feed The test much achieve a Testwork: Bond ball mill work index

Rod Mill an overview ScienceDirect Topics

347 Bond rod mill standard test Standard conditions for determining the work index of rod mills under laboratory conditions are: mill size = 305 mm (internal diameter) Dec 12, 2016 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work IndexBall Mill Design/Power CalculationThe Bond's standard ball mill is used to determine the work index value of differ ent samples The Bond work index is defined as the kilowatthours per short ton required to break from infinite size to a product size of 80% passing 100 µmCORRELATION BETWEEN BOND WORK INDEX AND The EF4 formula requires both the rod mill and ball mill work index (rod mill Wi is used to calculate the optimal feed size) and because this is a “singlestage ball mill” calculation, the F80is actually the rod mill feed size (10,000 µm) from Table 1 and the P80is the ball mill circuit productC O N S U L T I N G L T D TECHNICAL MEMORANDUMMilling – Rod / Ball Mills including Bond Ball Work / Grindability Index MARC manufactures a wide range of ball and rod mills to suit most metallurgical laboratory applications Our range extends from small 6L jartype mills that are manually positioned on rollers to large 30L size millsMilling – Rod / Ball Mills including Bond Ball Work

A Method of C alculating Autogenous/ SemiAutogenous

The ball fi mill work index is con rmed at 16 kWh/t The operating fi work index, though, is in the range of 21 kWh/t to 25 kWh/t showing high ineffi ciency This raises the point that, in some cases, the Bond EF4 oversize factor calculation is not suf cient to compensate fi for the milling inef ciencies that ariseBond’s approach consists of determining the ore hardness characteristics, or Work Index (Wi) via standardized laboratory testwork The full suite of Bond comminution tests provide the Ball Mill Work Index (BWi), the Rod Mill Work Index (RWi), the Crusher Work Index (CWi) and the Abrasion Index (Ai)Orway Mineral Consultants Canada Ltd Mississauga, ON Generally, Bond work index is a common method for selecting comminution equipment as well as estimation of grinding efficiency and calculating required power In the current research, a simple, fast and accurate procedure is introduced to find the(PDF) determination of Bond rodmill work index by The Titan Bond Work Index Rod Mill is onepiece cast construction with integral wave liners of a form described by Bond This mill is used to perform the necessary metallurgical testing to determine the grinding characteristics of ores and power requirements for operating productionsize rod millsBond Work Index Rod Mill Titan Process Equipment LtdJan 01, 2013 To calculate Bond rodmill work indices, the four samples were screened and the particle size distributions plotted in Fig 2The plot was used to find F 80 of the samples for calculations Fig 3, Fig 4 show the grinding kinetics of Pb, Cu, Fe, and Mn ores in the Bond rodmill in different testsieves The slopes of all lines in the figures are equal to the k value of Eq determination of Bond rodmill work index by

Bond Index Ball Mill / Rod Mill BT 100 XL RETSCH

The grinding jar for the Bond Index Rod Mill is 12″ x 24″ in size and has a waveshaped design At least 15 to 20 kg sample material is required to simulate a closed grinding circuit in a ball or rod mill The Rod Mill Work Index (RWI) is used for particle size determination in a size range from 25 mm down to 21 mm whereas Ball Mill Work Generally, Bond work index is a common method for selecting comminution equipment as well as estimation of grinding efficiency and calculating required power In the current research, a simple, fast and accurate procedure is introduced to find the rodmill work index based on the conventional Bond work index determination of Bond rodmill work index by Generally, Bond work index is a common method for selecting comminution equipment as well as estimation of grinding efficiency and calculating required power In the current research, a simple, fast and accurate procedure is introduced to find the(PDF) determination of Bond rodmill work index by Milling – Rod / Ball Mills including Bond Ball Work / Grindability Index MARC manufactures a wide range of ball and rod mills to suit most metallurgical laboratory applications Our range extends from small 6L jartype mills that are manually positioned on rollers to large 30L size millsMilling – Rod / Ball Mills including Bond Ball Work The Bond ball mill work index is one of the most commonly used grindability tests in mining, and is often referred to as the Bond work index The test is a 'lockedcycle' test where ground product is removed from test cycles and replaced by fresh feedTestwork: Bond ball mill work index

A Method of C alculating Autogenous/ SemiAutogenous

rod mill work index has not been de ned as yet The ball fi mill work index is con rmed at 16 kWh/t The operating fi work index, though, is in the range of 21 kWh/t to 25 kWh/t showing high ineffi ciency This raises the point that, in some cases, the Bond EF4 Jan 01, 2016 Bond rod mill work index, RW i • –5 mm • Bond ball mill work index, BW i The correlation between coarse particle comminution parameters tends to be rather poor as testing hardness of coarse particles tends to be dominated by breakage through fractures and fissures in the rock rather than through the rock itselfSize Reduction and Energy Requirement ScienceDirectstandard Bond crushing, and rod mill work indices, abrasion indices and by Dawson for Bond Ball Mill Work Index tests using crushed feed, and Standard Autogenous Grinding Design (SAGDesign) Tests, patented by Outokumpu (See reference 8 below) The comparison of these results gives context to how the various measurements relate to eachComparison of Ore Hardness Measurements for Grinding Mill Bond Work Index for Rod Mill Product Image Introduction The Bond Work Index for Ball Mill is a special equipment for testing Bond ball mill work index Simple lab test can choose ball mill by power method or judge the effects of material properties change to the ball milling process or the operation condition of crusher by using this China Bond Work Index for Rod Mill Manufacturers and SuppliersBond’s approach consists of determining the ore hardness characteristics, or Work Index (Wi) via standardized laboratory testwork The full suite of Bond comminution tests provide the Ball Mill Work Index (BWi), the Rod Mill Work Index (RWi), the Crusher Work Index (CWi) and the Abrasion Index Orway Mineral Consultants Canada Ltd Mississauga, ON