Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

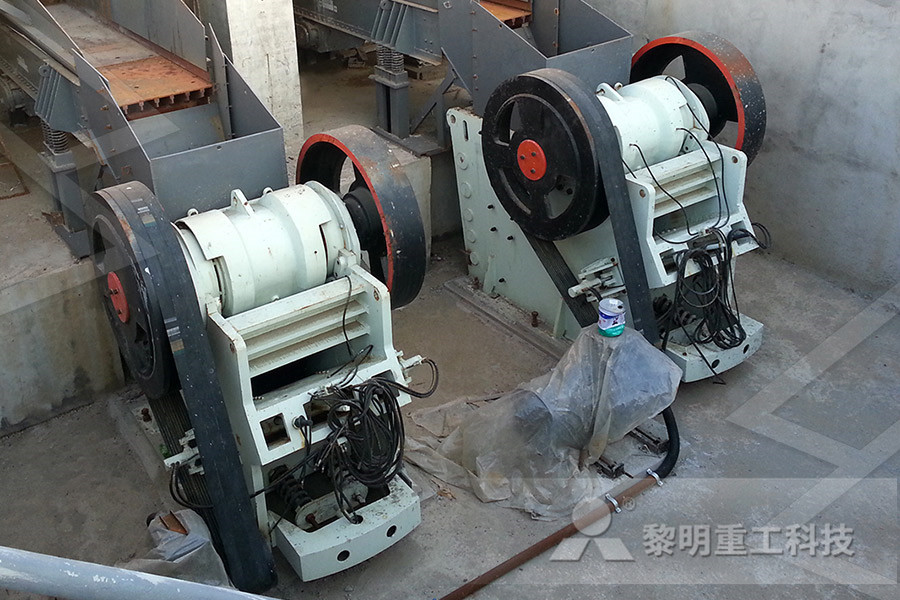

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

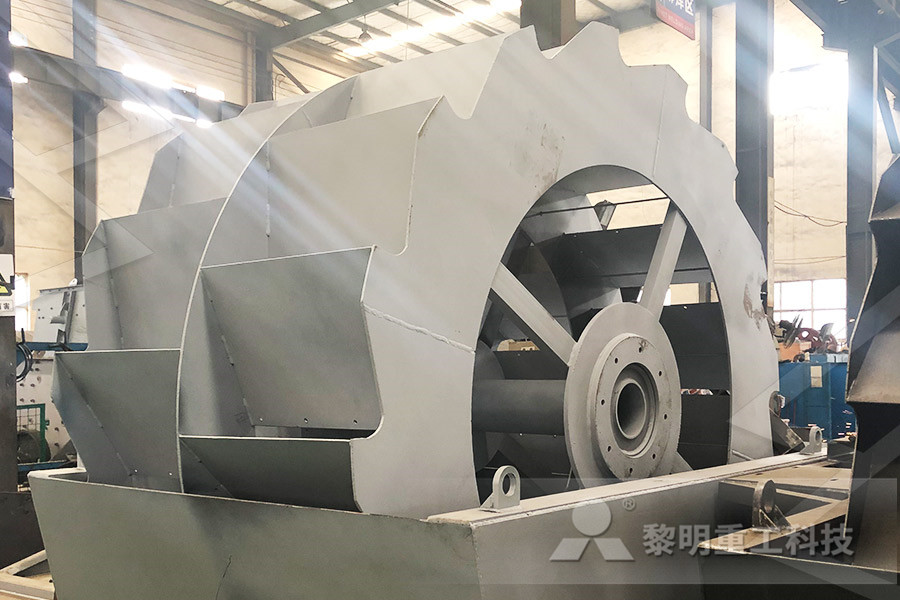

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Worlds largest flotation cells improve copper and

Oct 25, 2018 In 2017, installation work for the two new flotation cells began, thus the rougher capacity was dramatically expanded from approx 3043 m 3 to 4303 m 3 The startup of the new flotation cells took place during the first quarter of 2018A modal examination of the products produced by the copper flotation rougherscavenger circuit reveal important information regarding the limits to the efficiency of the process, imposed by mineralogy, fragmentation and flotation capacity Let’s discusses various aspects of rougher flotation circuit performance and how to evaluate its results Evaluating Copper RougherScavenger Flotation Circuit The existing Section 1 bulk rougher lines consist of three parallel lines of 18 cells per line with a total flotation capacity of approx 1529 m 3Section 2 bulk rougher stage also consists of three parallel lines, two of the lines equivalent to the flotation lines in Section 1 and one line consists of 13 cells with a net volume of 38 m 3 resulting in a total flotation capacity for the full World's largest flotation cells improve copper and This online calculator helps you on how to calculate or estimate either what size/volume flotation cell and well as conditioning tank + how many flotation cells your bank needs to accommodate the retention time you need Design Retention time is usually obtained from laboratory testwork and proper use of LabtoPlant flotation scaleup factors An Example of flotation cell capacity and circuit Calculate Flotation Cell Capacities Volume vs Retention TimeCopper Flotation Cell Capacity Copper flotation cell capacity the existing section 1 bulk rougher lines consist of three parallel lines of 18 cells per line with a total flotation capacity of approx 1529 m n 2 bulk rougher stage also consists of three parallel lines two of the lines equivalent to the flotation lines in section 1 and one line Copper Flotation Cell Machines CapacityCrusher

Separation efficiency improvement of a low grade copper

The copper flotation circuits upgrade copper content by a If additional water is added to dilute the contents of the flotation cell, and the flow rate of water to the concentrate remains the same, the water recovery will additional flotation capacity would be required in the cleaning circuitCopper flotation recovery by size (P D Munro and SE Munro (2015) derived from public data presented by Rio Tinto staff with Cadia East data added) The recovery of coarse copper sulphide composite particles via flotation is a function of inherentNEWCREST’S INDUSTRY FIRST APPLICATION Eriez FlotationMineral carrying rates across the pulpfroth interface in the range of 1432 tph/m2and bubble surface coverage between 7 and 22 %, have been determined in large rougher flotation cells (100, 160 On the Carrying Capacity Limitation in Large Flotation CellsThe floatation chamber has a capacity of 27 l and is also equipped with conventional systems to introduce air and mechanical agitation able to maintain the suspension of metallurgical pulp In the upper part of the cell there is an area in which the foam is recovered for analysis by a Flotation Cell an overview ScienceDirect TopicsFlotation Cell Read more About us Founded in 1997, Shandong Xinhai Mining Technology Equipment Inc,under Xinhai is a stockholding high and new technology enterprise to provide the Turnkey Solution for Mineral Processing Plant What you need is what we can do! In the future, Xinhai will continue to rely on three big supporting "technology large conveying capacity flotation cell system machine

Worlds largest flotation cells improve copper and

Oct 25, 2018 World's largest flotation cells improve copper and molybdenum recovery in Mexico to the flotation lines in Section 1 and one line consists of 13 cells with a net volume of 38 m 3 resulting in a total flotation capacity for the full section of approx 1513 m 3 Figure 2 Schematic flowsheet of the Buenavista del Cobre Concentrator 1The existing Section 1 bulk rougher lines consist of three parallel lines of 18 cells per line with a total flotation capacity of approx 1529 m 3Section 2 bulk rougher stage also consists of three parallel lines, two of the lines equivalent to the flotation lines in Section 1 and one line consists of 13 cells with a net volume of 38 m 3 resulting in a total flotation capacity for the full World's largest flotation cells improve copper and In the case of copper minerals, the particles adhere to this froth, which is separated, whereas the great bulk of the useless material sinks to the bottom of the tanks By varying the chemical conditions within the cells different results can be obtained, thereby making flotation highly selective in skilled hands60 Centuries of Copper: The Flotation ProcessCopper Flotation Cell Capacity Copper flotation cell capacity the existing section 1 bulk rougher lines consist of three parallel lines of 18 cells per line with a total flotation capacity of approx 1529 m n 2 bulk rougher stage also consists of three parallel lines two of the lines equivalent to the flotation lines in section 1 and one line Copper Flotation Cell Machines CapacityCrusherIts large capacity makes the Outotec TankCell e630 particularly suitable for rougher and scavenger duties in copper, coppermolybdenum, gold and other base metal applications After successful startup, Outotec's metallurgical team is now working closely with Grupo Mexico for the tuning and optimisation of the flotation cellsOutotec flotation cells improve copper recovery at

Enhancing the Performance of CuMo Circuits Jameson

capacity The Jameson Cell provides an excellent device to achieve moderate recovery at high carrying capacity and excellent separation from nonfloatable gangue Its use where valuable minerals are to be floated such as in the bulk flotation of copper minerals and molybdenite takesFlotation cell is widely used for roughing, concentrating and reverse flotation of nonferrous metals that include copper, lead, zinc, nickel and molybdenum, ferrous metal and nonmetallic minerals Production capacity : Flotation cell is widely used for roughing, concentrating and reverse flotation of nonferrous metals that include copper, lead XJB Rod type Flotation machine Yantai Jinpeng Mining Copper Challenge Engineering, design, installation, and recovery in the flotation cell while also reducing power consumption and the risk of sanding Froth management solution The Outotec cPlant is a lowcapacity flotation plant equipped with Outotec FloatForce OUTOTEC FLOTATION TECHNOLOGIESThe high intensity of the Jameson Cell means that it is much shorter than conventional column flotation cells (see Figure 1), and it does not require air compressors to aerate the suspension of ground ore particles and water (known as a slurry or pulp) in the flotation cell The lack of a requirement for compressed air and the lack of moving parts means that power consumption is less than for Jameson cell Wikipediacopper circuit and one in the pyrite circuit), two Jameson Cells to improve ne gangue rejection fi and a bank of 5 × Outotec TC30s to recovery copper and gold from the reground pyrite stream The equipment was purchased direct from vendors and an engineering rm contracted to design fi and install the multivendor reconfi guration upgradeTelfer Processing Plant Upgrade Jameson cell

column flotation cells copper ore lanuovalocandaeu

copper flotation where the pilot Jameson Cell was operated on the column feed and achieved significantly improved carrying capacities compared to the operating columns Improvements up to a factor of three were seen and are shown in Figure 4 00 05 10 15 20 25 30 35 00 05 10 15 20 25 30 Bubble Size (mm) Superficial Gas Velocity In order to test the processing capacity of flotation cell, Xinhai made flotation cell series and parallel two kinds of test respectively, after many experiments of the two methods, Xinhai adopted flotation cell series for the copper plant: start two ball mills, the capacity is 110 t/h, the pulp volume is 28552 m3/h, then the groove surface JJF Flotation, Wemco Flotation XinhaiA Denver Sub A flotation cell of capacity 250 gms was used for the batch flotation experiments Atomic absorption spectrophotometer was used for copper assays and microscopy for selectivity and liberation studies Melbourne tap water was used throughout the experimentsKinetics of Flotation of Copper Tailing from Benambra SuperCell Flotation Cells ® is the world leader in large cell technology with the greatest installed capacity of any flotation manufacturer (Above) 350m3 SuperCell installed with a DorrOliver mechanism in a copper installation in the USAFlotation technology DorrOliver Eimco PDF The existing Section 1 bulk rougher lines consist of three parallel lines of 18 cells per line with a total flotation capacity of approx 1529 m 3Section 2 bulk rougher stage also consists of three parallel lines, two of the lines equivalent to the flotation lines in Section 1 and one line consists of 13 cells with a net volume of 38 m 3 resulting in a total flotation capacity World's largest flotation cells improve copper and

60 Centuries of Copper: The Flotation Process

In the case of copper minerals, the particles adhere to this froth, which is separated, whereas the great bulk of the useless material sinks to the bottom of the tanks By varying the chemical conditions within the cells different results can be obtained, thereby making flotation highly selective in skilled handsA Denver Sub A flotation cell of capacity 250 gms was used for the batch flotation experiments Atomic absorption spectrophotometer was used for copper assays and microscopy for selectivity and liberation studies Melbourne tap water was used throughout the experimentsKinetics of Flotation of Copper Tailing from Benambra In order to test the processing capacity of flotation cell, Xinhai made flotation cell series and parallel two kinds of test respectively, after many experiments of the two methods, Xinhai adopted flotation cell series for the copper plant: start two ball mills, the capacity is 110 t/h, the pulp volume is 28552 m3/h, then the groove surface JJF Flotation, Wemco Flotation Xinhaicopper flotation where the pilot Jameson Cell was operated on the column feed and achieved significantly improved carrying capacities compared to the operating columns Improvements up to a factor of three were seen and are shown in Figure 4 00 05 10 15 20 25 30 35 00 05 10 15 20 25 30 Bubble Size (mm) Superficial Gas Velocity column flotation cells copper ore lanuovalocandaeuIts large capacity makes the Outotec TankCell e630 particularly suitable for rougher and scavenger duties in copper, coppermolybdenum, gold and other base metal applications After successful startup, Outotec's metallurgical team is now working closely with Grupo Mexico for the tuning and optimisation of the flotation cellsOutotec flotation cells improve copper recovery at

:: Selecting Flotation Cells: How Many and What Size?

These notes were contributed by Peter Bourke, Manager, Flotation Cells, for Outokumpu Technology Pty Ltd He has more than a decade's experience at the leading edge of the development of flotation cells, having been involved successively in the installation of Outokumpu's first 100, 150 and 200 cubic metre float cellsCopper Challenge Engineering, design, installation, and recovery in the flotation cell while also reducing power consumption and the risk of sanding Froth management solution The Outotec cPlant is a lowcapacity flotation plant equipped with Outotec FloatForce OUTOTEC FLOTATION TECHNOLOGIESThe high intensity of the Jameson Cell means that it is much shorter than conventional column flotation cells (see Figure 1), and it does not require air compressors to aerate the suspension of ground ore particles and water (known as a slurry or pulp) in the flotation cell The lack of a requirement for compressed air and the lack of moving parts means that power consumption is less than for Jameson cell Wikipediacopper circuit and one in the pyrite circuit), two Jameson Cells to improve ne gangue rejection fi and a bank of 5 × Outotec TC30s to recovery copper and gold from the reground pyrite stream The equipment was purchased direct from vendors and an engineering rm contracted to design fi and install the multivendor reconfi guration upgradeTelfer Processing Plant Upgrade Jameson cellMineral carrying rates across the pulpfroth interface in the range of 1432 tph/m 2 and bubble surface coverage between 7 and 22 %, have been determined in large rougher flotation cells (100 On the Carrying Capacity Limitation in Large Flotation Cells

Flotation technology DorrOliver Eimco PDF

SuperCell Flotation Cells ® is the world leader in large cell technology with the greatest installed capacity of any flotation manufacturer (Above) 350m3 SuperCell installed with a DorrOliver mechanism in a copper installation in the USAresidence time and carrying capacity Inco, CuIMo cleaning at Magma Copper, eu cleaning at Los Bronces, Exxon, Chile) characteristics change from cell to cell Industrial flotation columns are square or circular, typically 053m in diameter or side, and 1215m height Since their invention, square columns have been marketedCOLUMN FLOTATION MODELLING AND TECHNOLOGYFlotation Company of Canada on moly cleaning at Noranda’s Les Mines Gaspé (Cienski and Coffin, 1981; Coffin and Miszczak, 1982) Today column flotation has become an accepted means of froth flotation for a fairly broad range of applications, in particular the cleaning of sulfides (copper, zinc, lead and molybdenite) andColumn Flotation SGS