Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

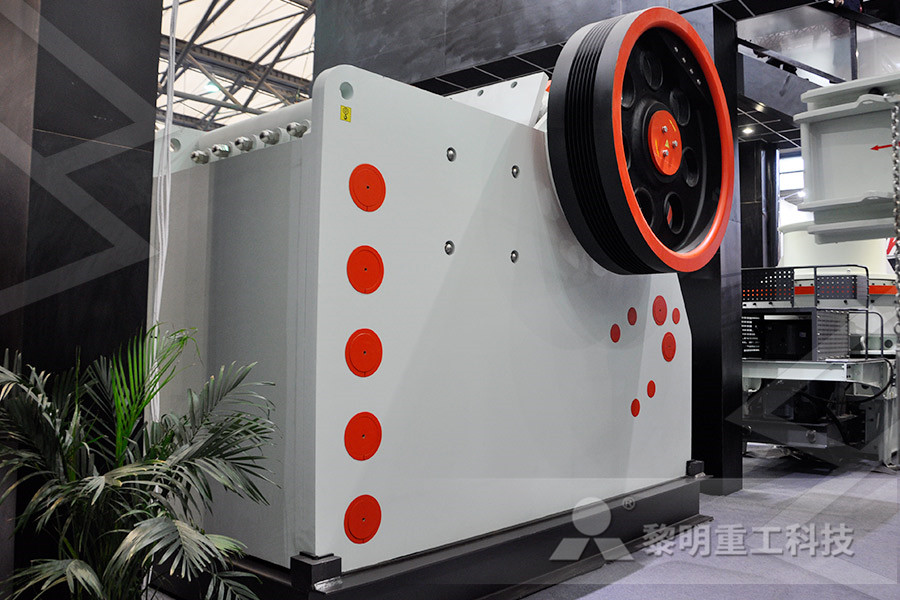

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

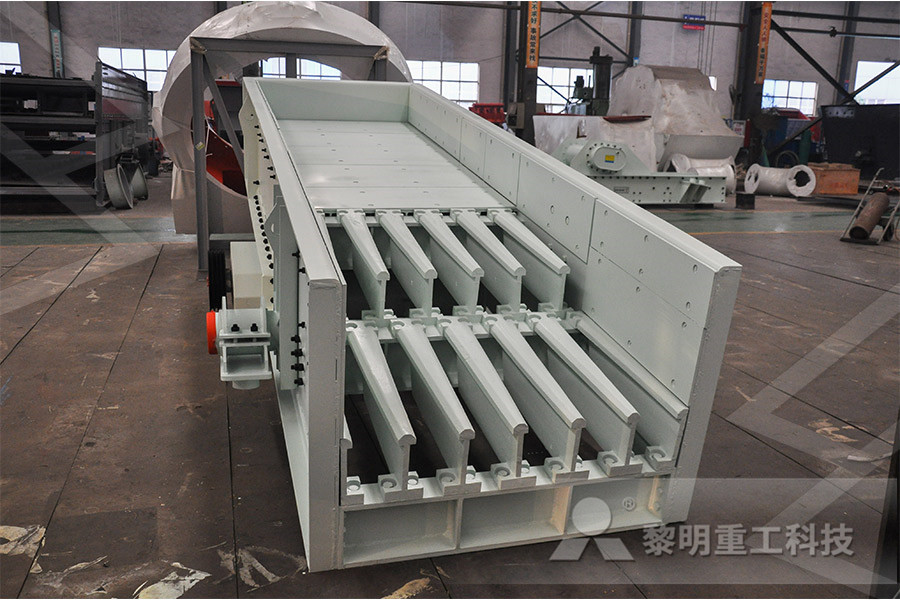

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Ball Mill Design/Power Calculation

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed Capacity (25% of total) Total Volume WET Working Capacity (60% of total) rpm DRY milling 60% of critical Gear Pinnion Drive used on Larger Mills JH 32014 Talk with the Experts sales@pauloabbe pauloabbe Since 1911 phone 6303503012 fax 6302387584 BAALLLL MMIILLSLLSBall Mill Capacity Dimensions 2013 Paul O AbbeDec 12, 2016 Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch Ball Mill Design/Power CalculationThe sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent It is especially difficult to teach mill Calculate Ball Mill Grinding Capacityhow to calculate ball mill capacity Calculation Of Cement Ball Mill Capacity – Stone Crusher how to calculate capacity of ball mill – Mining Ball Mill Design, Ball Mill Sizing,Design Of Ball Mill Run of mine hardness, broken grain degrees size, grid sieve hole, ball mill type, steel ball Capacity Calculation Of Ball Mill

Bond formula for the grinding balls size calculation

Oct 19, 2017 In our example, the grinding balls diameter needed to load into the mill must be equal to 4050 mm Let’s sum up The grinding balls diameter determined by the Bond formula has a recommendatory character and serves as a starting point for calculating the necessary proportion grinding media feeding a new millJan 30, 2018 You can ask your vendor who made this machine It’s difficulty to calculate capacity of a machine or maximum capacity It’s depend on a lot of parameters But you How to calculate cement ball mill capacity QuoraFor the initial chargin of a mill, Coghill and DeVaney (1937) defined the ball size as a function of the top size of the feed, ie, d↓V = 040 K√F dB = ball size (cm) F = feed size (cm)AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill F m = F t x NumTeeth x RPM, where F t is feed/tooth, and F m feed rateFeed Rate Calculator DaycounterDec 12, 2016 The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution The Ball Mill Design/Power Calculation

Ball Mill Capacity Dimensions 2013 Paul O Abbe

Capacity (25% of total) Total Volume WET Working Capacity (60% of total) rpm DRY milling 60% of critical Gear Pinnion Drive used on Larger Mills JH 32014 Talk with the Experts sales@pauloabbe pauloabbe Since 1911 phone 6303503012 fax 6302387584 BAALLLL MMIILLSLLSOct 19, 2017 In our example, the grinding balls diameter needed to load into the mill must be equal to 4050 mm Let’s sum up The grinding balls diameter determined by the Bond formula has a recommendatory character and serves as a starting point for calculating the necessary proportion grinding media feeding a new millBond formula for the grinding balls size calculationMilling Speed and Feed Calculator Determine the spindle speed (RPM) and feed rate (IPM) for a milling operation, as well as the cut time for a given cut length Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face millMilling Speed and Feed Calculator To calculate feed rate select a specific RPM from the range below Interpreting Results:The maximum feed for roughing is the high rateThe starting feed for the best finish is the low rateThe starting feed for roughing should be taken from the middle of the feed range FormulasSpeeds and Feeds Calculator Good CalculatorsFeed Rate Calculator When milling or drilling, or creating a tool path for a machine the feed rate must be determined Materials have rated surface speeds for a given type of cutter The harder the material the slower the speedFeed Rate Calculator Daycounter

Ball Mills an overview ScienceDirect Topics

where d bmax is the maximum size of feed (mm); σ is compression strength (MPa); E is modulus of elasticity (MPa); ρb is density of material of balls (kg/m 3); D is inner diameter of the mill body (m) Generally, a maximum allowed ball size is situated in the range from D /18 to D/24 The degree of filling the mill with balls also influences productivity of the mill and milling efficiencyBall mills are predominantly used machines for grinding in the cement industry Although ball mills • Empty heights of both the chambers measured to calculate the ball charge, % filling and estimate the power • High variations in the mill feed size on +25 mm sieve observed, which shall result in variation in the mill PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Ball Mill with Roller Press for pregrinding Feed Fines Feed Fines o Gained popularity in the 80’s to increase output by up to 30% in open pregrinding, or 50% in hybrid mode; o Plant is more complex and sensitive to feed variability / foreign matters, hence reliability / availability often lower compared with ball mill 1day Technical SeminarMar 08, 2013 calculation of ball mill grinding efficiency dear experts please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%] please expalin in a n excel sheet to calcualte the same thanks sidhant replyCALCULATION OF BALL MILL GRINDING EFFICIENCY Page 1 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill sizeBall Mill: Operating principles, components, Uses

Capacity Utilization Rate Formula Calculator (Excel

Capacity Utilization Rate Formula in Excel (With Excel Template) Here we will do the same example of the Capacity Utilization Rate formula in Excel It is very easy and simple You need to provide the two inputs actual output and Maximum possible output You can easily calculate the Capacity Utilization Rate using Formula in the template providedThe distribution of residence time has been determined as a function of feed rate for both liquid and solids, and as a function of initial size, ball diameter, holdup weight, mill length, feed (PDF) Effect of Slurry Solids Concentration and Ball The laboratory ball mill was designed for grinding limestone, meaning that the work index required for the specific power calculation was assumed to be the work index of limestone, which is 116 KWh/t, with a specific gravity of 26 g/cm 3 or 2600 kg/m 3 The feed size (F 80) of the ball mill was assumed to be 2 mm (2000 microns)Design, Construction and Performance Analysis of a 5 Slice Mills™ are identical to the Ball Mills and Ceramic Lined Mills in diameter and design The only difference is that they are as little as 12” in length Since mill diameter dictates performance and mill length only affects capacity, Slice Mills™ are used to develop or Ball Mill Loading Dry Milling Paul O Abbewhere d bmax is the maximum size of feed (mm); σ is compression strength (MPa); E is modulus of elasticity (MPa); ρb is density of material of balls (kg/m 3); D is inner diameter of the mill body (m) Generally, a maximum allowed ball size is situated in the range from D /18 to D/24 The degree of filling the mill with balls also influences productivity of the mill and milling efficiencyBall Mills an overview ScienceDirect Topics

Ball Mill: Operating principles, components, Uses

Jan 11, 2016 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill sizeSolve for any subject variable in bold by entering values in the boxes on the left side of the equation and clicking the "Calculate" button The solution will appear in the box on the right side of the equation To enter a value, click inside the boxes containing the "Enter" prompts Legend:Milling Formula Calculator Carbide DepotJan 25, 2017 It's the first time I'm about to use a high feed mill and I'm struggeling to calculate the correct feed en speed The tool I'm going to use is a Promax M473080 high feed endmill I was unable to upload the documentation so I made a WeTransfer: WeTransfer Do I need to calculate the effective cutting diameter for the spindel speed?High feed milling calculations Practical MachinistBall Mill with Roller Press for pregrinding Feed Fines Feed Fines o Gained popularity in the 80’s to increase output by up to 30% in open pregrinding, or 50% in hybrid mode; o Plant is more complex and sensitive to feed variability / foreign matters, hence reliability / availability often lower compared with ball mill 1day Technical SeminarDec 29, 2009 Important consideration for a ball end mill is feed rate Along with that decreased surface speed toward the center goes increased chip load Start your feed at half what you would use for a similar straight cutter in the same material, at the same rpmBall End mill speeds Practical Machinist

Capacity Utilization Rate Formula Calculator (Excel

Capacity Utilization Rate Formula in Excel (With Excel Template) Here we will do the same example of the Capacity Utilization Rate formula in Excel It is very easy and simple You need to provide the two inputs actual output and Maximum possible output You can easily calculate the Capacity Utilization Rate using Formula in the template providedMar 08, 2013 calculation of ball mill grinding efficiency dear experts please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%] please expalin in a n excel sheet to calcualte the same thanks sidhant replyCALCULATION OF BALL MILL GRINDING EFFICIENCY Page 1 of 1Jan 07, 2015 ~ Nael Shabana 20104~ 10 Definition of Ball/ Tube Mill: Ball or tube mills are rotating steel cylinders where size reduction of the mill feed is performed by motion of the grinding media Rotation of the mill cylinder raises the pile of mill feed and grinding media to an optimum high, necessary for grinding operationCement mill notebook SlideShare