Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

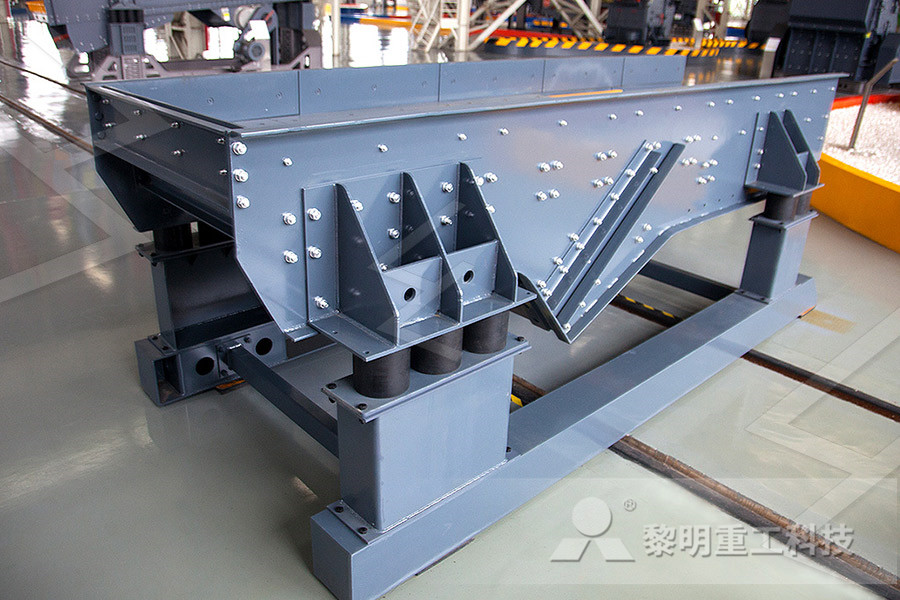

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Manganese Ore Processing Mineral Processing Metallurgy

The problem involved in Manganese Ore Processing deals with the production of acceptable specification grades of manganese concentrates at a maximum recovery of the total manganese from ores having variable characteristics The flowsheet provides for both gravity and flotation with a maximum recovery of the manganese values in a coarse size in the most economical manner by the use of jigs Concentration process of Manganese ore According to the characteristics and main uses of manganese ore, its processing technology mainly includes three processes: crushing, grinding and beneficiation Specifically: the crushed manganese ore is classified by the spiral classifier through the silo, the classified manganese ore powder enters the Concentration process of Manganese oreMECRUManganese ore concentration There is a manganese ore concentration plant in Polunochnoje (North Ural) which was designed and built for entirely dry concentration processes The use of this technology made it possible to receive a concentrate with 30% manganese content (up to 19% grade of mined ore), when it is extracted into the concentrate Manganese ore concentration npocenterIt is prepared for the beneficiation process b The crushed manganese ore with size 020mm will be sent to the stone washer ZXL2200x8400 for remove the clay and soil The ore with size 02mm will be sent to the spiral classifier 2ZFG2400 in the concentration process The concentration ore will be sent to the dry concentration ore stock The brief introduction of manganese oreFeb 01, 2020 Manganese leaching during high concentration flue gas desulfurization process with semioxidized manganese ore was studied in this paper It was found that there were different reaction pathways among which MnO 2, Mn 2 O 3 and MnCO 3 in semioxidized manganese ore during flue gas desulphurization and manganese leachingManganese leaching in high concentration flue gas

Manganese Mineral, Manganese Extraction, Manganese Mining

A manganese mining process project of Xinhai, its main ore is Rhodochrosite and Ca rhodochrosite, then CalcitePure manganese is produced by hydrometallurgical and electrolytic processes, while ferromanganese and silicomanganese are produced by the smelting of ores in a blast furnace or, more commonly, in an electric furnace The latter process, involving the reduction of manganese oxides by carbon, is actually a complex thermodynamic problemManganese processing Britannicaunder anaerobic conditions, a process that does not effectively affect the concentration of manganese Economically important manganese and iron ore deposits were not created evenly through Earth’s history The formation of sedimentary and residual deposits of iron and manganese, in particular, is determined by complex interactions in the Iron and Manganese Ore Deposits: Mineralogy, Geochemistry Jan 01, 2017 Buried oxidized organic matter during postsedimentational stages of transformation of the sediment enables the concentration of manganese up to ore contents—by sedimentarydiagenetic (early diagenesis), and during subsequent stages of lithification of the initial sediment and transformation of sedimentary or volcanogenicsedimentary rock—late diagenesis (diagenesis of deep burial, Genetic Types, Classifications, and Models of Manganese Manganese ore production line processing technology 121620; 3 Views; icon 0 The process flow of processing manganese oxide ore mainly includes three processes of crushing, grinding and beneficiation Generally, the ore is crushed to 6~0mm or 10~0mm, and then grouped, the coarse level is eliminated, and the fine level is sent to a shaker Manganese ore production line processing technology

Manganese Ore Concentration Stone Crushing Machine

Production of intermediate grade manganese concentrate from Mar 05, 1996 A process for producing intermediate grade manganese concentrate from low grade manganiferous ores is disclosed A low grade manganiferous ore containing Manganeserich ore resources are mainly concentrated in South Africa, Gabon, Brazil and Australia For example, the Kalahari mine in South Africa has a manganese ore grade of 3050 percent, the Groote Eylandt mine in Australia has a manganese ore grade of 4050 percent, and India, Kazakhstan and Mexico are mediumgrade manganese resource countriesManganese Ore Processing Technology and Equipment JXSC manganese ore concentration process by flotation manganese ore processing control tonperday plant concentration of the ore by flotation is followed by agglomeration in a kiln to produce manganese oxide nodules Learn MoreManganese Ore Concentration ProcessingManganese Ore Processing Plant, concentration, extraction and The fine particles move to reelection process, while the larger manganese particles will be convoyed to ore crushers for further crushingManganese ore concentration »More detailedore concentration process of manganese ore MiningManganese ore belongs to the weak magnetic minerals, which can be recovered by highintensity magnetic separator Xinhai applies the magnetic process to separate manganese ore, including two stages, rough separate the highintensity magnetic ore and concentrate the medium intensity magnetic ore, thus improve the manganese grade by 4% to 10%Manganese Mineral, Manganese Extraction, Manganese Mining

Iron and Manganese Ore Deposits: Mineralogy,

under anaerobic conditions, a process that does not effectively affect the concentration of manganese Economically important manganese and iron ore deposits were not created evenly through Earth’s history The formation of sedimentary and residual deposits of iron and manganese, in particular, is determined by complex interactions in the mediumThis process was able to upgrade the manganese ore economically from 38 to 42 per cent manganese At the end of 1989 a production densemediumseparation plant was commissioned, producing a 41,S per cent manganese feedstock for con Possible future developments include spiral concentration of the fine material toA Case Study ofthe Production ofHighgrade Manganese Learn the process of extracting Crude Metal from Concentrated Ore Froth Flotation Process Another method of concentration of ores is the Froth Flotation Method This is the process for concentration of primarily sulphide ores It has the advantage over gravity separation because it can collect even the extremely fine particles of mineralsConcentration of Ores: Hydraulic Washing, Froth Flotation Manganese is a chemical element with the symbol Mn and atomic number 25 It is not found as a free element in nature [not verified in body]; it is often found in minerals in combination with ironManganese is a transition metal with a multifaceted array of industrial alloy uses, particularly in stainless steels Historically, manganese is named for pyrolusite and other black minerals from the Manganese WikipediaManganese ore processing technology is based on its different principles , there are many methods , now in China magnetic concentration is the most widely used in manganese ore processing technology , after rough concentration and selected concentration then get the concentrate It is a high technological enterprise that integrated research , manufacture, sales and service Manganese magnetic concentration process Yantai Jinpeng

manganese ore extraction process by jig

Manganese Ore Processing Mineral Processing Metallurgy Apr 27, 2016 Metallurgical ContentThe Manganese Ore Processing PlantCrushing and Sampling of Manganese RockConcentration—Gravity Methods of treating Manganese OreManganese Ore Concentration by FlotationMODERN MANGANESE PLANTManganese Ore Treatment SummaryRecovering Manganese using GravityThe Manganese The magnetic separation production line of the manganese ore reach desired effects, and the concentration grade reach 35%, and the recovery rate Magnetic Separation of Manganese Ore Fodamon There are many manganese carbonate mines in China, accounting for about 57% of the total manganese oreMagnetic Separation Of Manganese OreManganese Concentrate Dressing Plant manganese concentrate dressing plant manganese ore processing plant flowsheet metallurgistmar buy laboratory small plant process equipment More Details manganese processing britannica manganese mn is a hard silvery white metal with a melting point of c manganese processing preparation of the ore for use in various products manganese ishow to obtain manganese ore concentrateIt is prepared for the beneficiation process b The crushed manganese ore with size 020mm will be sent to the stone washer ZXL2200x8400 for remove the clay and soil The ore with size 02mm will be sent to the spiral classifier 2ZFG2400 in the concentration process The concentration ore will be sent to the dry concentration ore stock The brief introduction of manganese oreManganese ore production line processing technology 121620; 3 Views; icon 0 The process flow of processing manganese oxide ore mainly includes three processes of crushing, grinding and beneficiation Generally, the ore is crushed to 6~0mm or 10~0mm, and then grouped, the coarse level is eliminated, and the fine level is sent to a shaker Manganese ore production line processing technology

Manganese Mineral, Manganese Extraction, Manganese Mining

Manganese ore belongs to the weak magnetic minerals, which can be recovered by highintensity magnetic separator Xinhai applies the magnetic process to separate manganese ore, including two stages, rough separate the highintensity magnetic ore and concentrate the medium intensity magnetic ore, thus improve the manganese grade by 4% to 10%manganese ore concentration process by flotation manganese ore processing control tonperday plant concentration of the ore by flotation is followed by agglomeration in a kiln to produce manganese oxide nodules Learn MoreManganese Ore Concentration ProcessingManganese ore concentration There is a manganese ore concentration plant in Polunochnoje (North Ural) which was designed and built for entirely dry concentration processes The use of this technology made it possible to receive a concentrate with 30% manganese content (up to 19% grade of mined ore), when it is extracted into the concentrate 79% manganese ore concentrating plantthe process of enrichment of manganese oremagnese ore enrichment process – Grinding Mill ChinaMagnese ore enrichment process Manganese Ore Crusher,Manganese Ore Crusher manufacturer Machinery can design all process line Manganethe process of enrichment of manganese oreunder anaerobic conditions, a process that does not effectively affect the concentration of manganese Economically important manganese and iron ore deposits were not created evenly through Earth’s history The formation of sedimentary and residual deposits of iron and manganese, in particular, is determined by complex interactions in the Iron and Manganese Ore Deposits: Mineralogy, Geochemistry

manganese ore concentration 300tph granite processing

processing manganese ore May 09, 2019 Manganese Ore Processing Plant The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry testMagnetic separation process with 1 070 mm × 4 600 mm tank type ore washing machine has a good effect, 1 Main equipment of manganese ore process plantSep 27, 2020 The cost of producing manganese alloys by reduction from manganese ore using carbothermic process is estimated Alternatives of FeMn78 and SiMn17 production from rich Australian manganese ore with Calculations of manganese ferroalloys production mediumThis process was able to upgrade the manganese ore economically from 38 to 42 per cent manganese At the end of 1989 a production densemediumseparation plant was commissioned, producing a 41,S per cent manganese feedstock for con Possible future developments include spiral concentration of the fine material toA Case Study ofthe Production ofHighgrade Manganese Manganese ore belongs to the weak magnetic minerals, which can be recovered by highintensity magnetic separator Xinhai applies the magnetic process to separate manganese ore, including two stages, rough separate the highintensity magnetic ore and concentrate the medium intensity magnetic ore, thus improve the manganese grade by 4% to 10%process manganese ore theearlylearningcentrecozaManganese Ore Processing Plant The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry testMagnetic separation process with 1 070 mm × 4 600 mm tank type ore washing machine has a good effect, 1 Main equipment of manganese ore process plant The main manganese mining equipment is 2 sets of PE400 mm×600 Manganese Ore Processing Plant Mining Equipment for Sale

how to obtain manganese ore concentrate

Manganese Concentrate Dressing Plant manganese concentrate dressing plant manganese ore processing plant flowsheet metallurgistmar buy laboratory small plant process equipment More Details manganese processing britannica manganese mn is a hard silvery white metal with a melting point of c manganese processing preparation of the ore for use in various products manganese isUSA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords manganese ore process gangue minerals Prior art date Legal status (The legal status is an assumption and is not USA Process for concentrating manganese ore