Solutions

Products

-

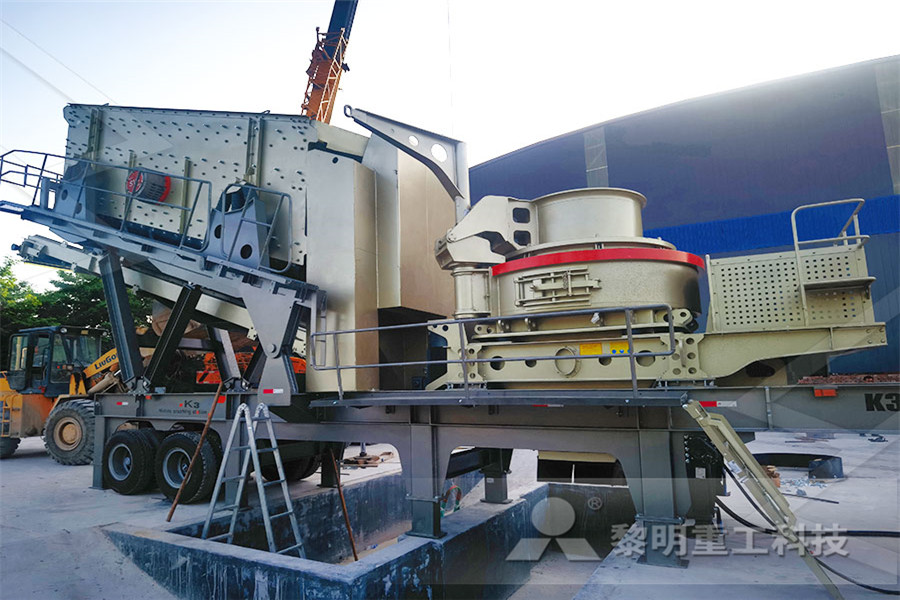

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

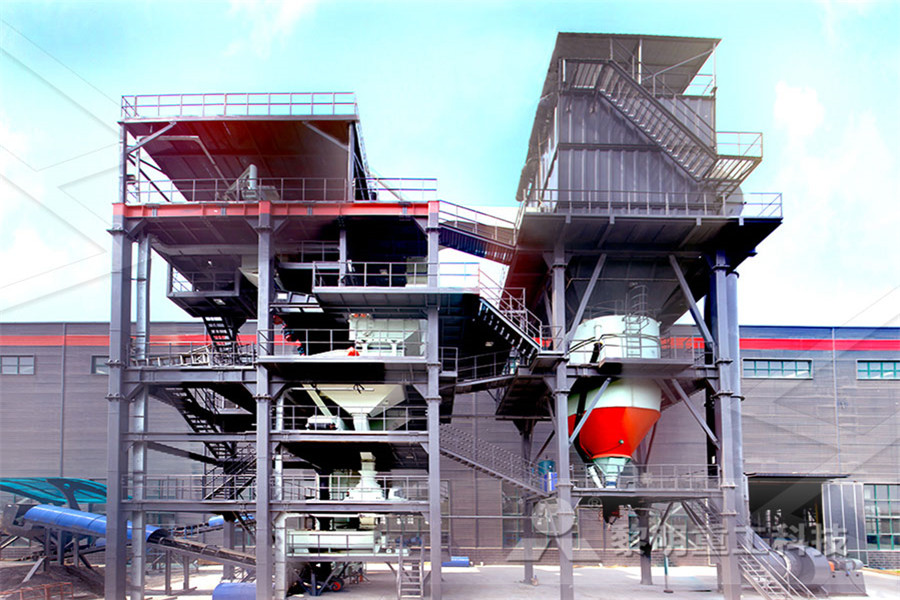

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

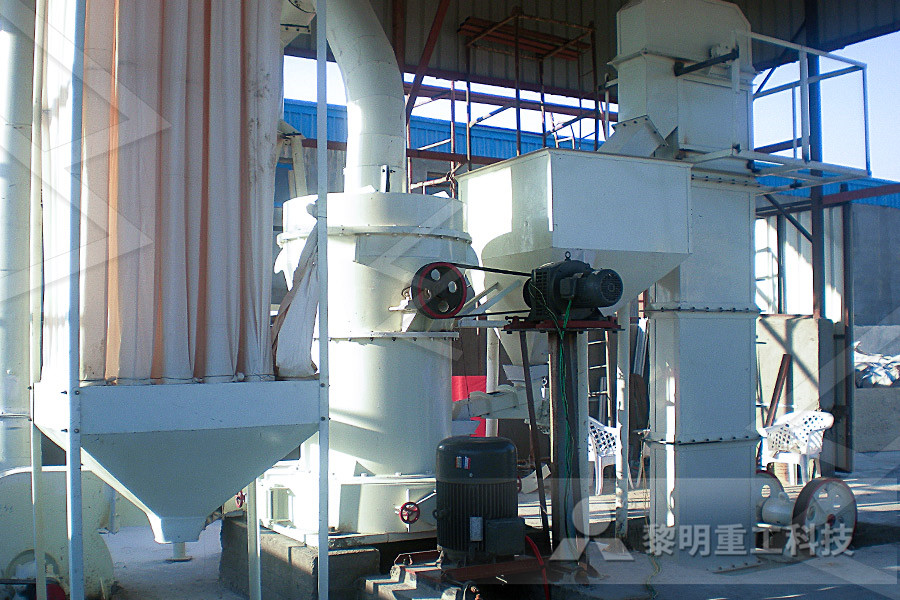

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Mobile Vertical Laminar Air Flow Vertical Laminar Air

Mobile Vertical Laminar Airflow units offers highest product protection by providing ISO Class 5 particle free work area suitable for handling critical materials and processes The work area is continuously supplied with positive pressure HEPA filtered vertical air flowvertical roller mill for sale « The New Blog Peoria Project In the vertical roller mill hydraulic system is installed in each of the tensioning rod the separated granular material is passing out of the air flow mill, and coarse mill, increased mill personnel a negative pressure, so that the mill work balance main operating parameters within the normal range of the grinding typical airflow balance of a vertical roller millThere are four main types of an air flow unit: Laminar airflow workstation, Horizontal laminar airflow hood/bench/cabinet, Vertical laminar air flow hood/bench/cabinet, Mobile laminar air flow A laminar airflow workstation has the air flow in vertical direction It is accompanied with a LED/UV lightAirflow Workstation Mobile, Vertical, Horizontal Laminar Operation Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the Vertical roller mill WikipediaThe high velocity air stream passing through the throat entrains the partially ground coal (4) and lifts it into the mill body As the flow area increases above the top grinding ring/spider level, the air velocity decreases and coarse particles (7) fall back to mix with the raw coal (1) on the rotating table while the finer particles (5) areApplication of CDF modelling to mill classifier design

Cement grinding Vertical roller mills versus ball mills

A lower air flow rate will lead to a lower inclination of the particle size distribution curve cement in a vertical roller mill, the layout, as shown in Figure 7, is prepared with provisions for recirculation of hot mill exit gas to the mill inlet to maintain a proper , A simplified design schematic of a vertical spindle mill is shown in Figure 1 Raw coal is transported on a conveyor the fuel flow out of the mill, and the return flow of rejected particles to the table (3) The mass flow of pulverised particles picked up by the primary air flow, to Modeling and Control of Coal Mill NTNUMoisture caution: The airflow through the mill’s de Laval nozzles is isentropic,meaning that the air expands and drops in temperature after it leaves the nozzlesHow to get better grinding performance with pneumatic ROLLER MILL Used in cement industry Vertical Mills used for Pregrinding of clinker (lumps to coarse powder) Finish grinding (lumps to powder) of Coal/Petcoke for kiln Raw materials for kiln Cement, OPC or mixed Slag, pure or mixed VRM Functions Vertical Roller Mill (VRM) Details feed gate (air lock) mill casing water injection dam ring louvre ring nozzle of material scraper mill outlet Vrm Presentation Mill (Grinding) CementVertical Cooler – Cross Flow Maximum Air Velocity = 350 feet per minute Horizontal Cooler Horizontal Coolers Reduce Air Flow Temperature is low and Moisture is low Reduce Air Flow Source: CPM California Pellet Mill Co Pellet Crumbling Roll Dia Corrugation TypePellet Cooling and Crumbling

How accurate primary airflow measurements improve plant

May 15, 2006 Mill puffs and explosions had occurred (as the expanded duct flow areas in the tables make clear) and had variable effects on each pulverizer’s pitot tube differentialtoinlet duct flow PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Air flow filter outlet (m³/h) Working press M (PDF) Performance Evaluation of Vertical Roller Mill in Today the airswept vertical roller mill is the standard solution for coal grinding installations And thanks to our continuous refinement of the ATOX coal mill over the years, today’s leading airswept vertical roller mill is the compact ATOX Offering high reliability, ATOX coal mill A lower air flow rate will lead to a lower inclination of the particle size distribution curve cement in a vertical roller mill, the layout, as shown in Figure 7, is prepared with provisions for recirculation of hot mill exit gas to the mill inlet to maintain a proper , Cement grinding Vertical roller mills versus ball millsvertical and horizontal flow cabinets is the same and the choice is largely a matter of user preference Horizontal flow cabinets create less turbulence at the work surface, as the airflow does not directly impinge upon it but rather is smoothly drawn across it The airflow on the Purair vertical flow cabinets directly strikes the work surfaceGeneral Purpose Laminar Flow Cabinets, 24 Air Science

Vertical Axis Wind Turbine an overview ScienceDirect

Looking downward from the top, a turbine with a Savonius rotor would look like two spoons facing opposite directions and linked at the center to the rotor axis (creating an ‘S’ shape in cross section (Fig 2014))Due to their curvature, the drag of the concave surface is higher than the convex surface, forcing the rotor to turn when the cups are exposed to wind (Mathew, 2006)ROLLER MILL Used in cement industry Vertical Mills used for Pregrinding of clinker (lumps to coarse powder) Finish grinding (lumps to powder) of Coal/Petcoke for kiln Raw materials for kiln Cement, OPC or mixed Slag, pure or mixed VRM Functions Vertical Roller Mill (VRM) Details feed gate (air lock) mill casing water injection dam ring louvre ring nozzle of material scraper mill outlet Vrm Presentation Mill (Grinding) CementNomenclatureBowl Mills 583 XRS / 803 XRP Bowl mills 58,80 stands for bowl diameter in inches If the number is even then its shallow bowl mill If the number is odd then its deep bowl mill 3 number of rollers three nos X frequency of power supply 50 cyclesIn USA ’x’ means 60 cycles R Raymond, name of the inventorPulverizer Plant OM AspectsVertical Laminar Flow Hoods Room air (in red) enters the system from above the HEPA filter; 9999% particlefree air is forced downward toward the work surface Vertical laminar flow hoods are often chosen because they resemble, on a small scale, the design of a laminar flow cleanroom, in which fan/filter units are typically positioned in the Horizontal vs Vertical Laminar Flow Hoods Terra The Arrow and Air Flow Direction To properly insert a new filter, look for the arrow! The arrow on your filter should always face the unit and away from the return air duct that carries the air that will be heated or cooled HVAC systems push the cool or warm air out and pull spent air in, recirculating the air throughout your homeDetermining Air Flow Arrow Direction to Properly Insert a

SOP for Cleaning and Operation of Laminar Air Flow

67 LAF: Laminar Air Flow Get ready to use editable documents in MSWord Format View List Share Tweet Share Ankur Choudhary is India's first professional pharmaceutical blogger, author and founder of Pharmaceutical Guidelines, a widelyread pharmaceutical blog since 2008Jul 27, 2017 However, it is more practical to install a vertical system on a level base, such as the ground or the top of a building Vibration can be an issue at times, and even increase the noise produced by the turbine Air flow at ground level can increase turbulence, thereby increasing vibration This can wear out the bearingVertical Axis Wind Turbines Advantages DisadvantagesSs Vertical Horizontal Laminar Air Flow, For Industrial Rs 63,000/no Get Quote Stainless Steel Polished Laminar Air Flow Chamber, For Laboratory Rs 90,000/ noLaminar Flow Cabinet Laminar Air Flow Cabinets Latest Jul 27, 2017 However, it is more practical to install a vertical system on a level base, such as the ground or the top of a building Vibration can be an issue at times, and even increase the noise produced by the turbine Air flow Vertical Axis Wind Turbines Advantages Disadvantagesvertical and horizontal flow cabinets is the same and the choice is largely a matter of user preference Horizontal flow cabinets create less turbulence at the work surface, as the airflow does not directly impinge upon it but rather is smoothly drawn across it The airflow on the Purair vertical flow General Purpose Laminar Flow Cabinets, 24 Air Science

Laminar Flow Cabinet Laminar Air Flow Cabinets Latest

Ss Vertical Horizontal Laminar Air Flow, For Industrial Rs 63,000/no Get Quote Stainless Steel Polished Laminar Air Flow Chamber, For Laboratory Rs 90,000/ noNomenclatureBowl Mills 583 XRS / 803 XRP Bowl mills 58,80 stands for bowl diameter in inches If the number is even then its shallow bowl mill If the number is odd then its deep bowl mill 3 number of Pulverizer Plant OM AspectsFigure 4 Darrieus vertical axis turbines principle of operation The resultant of the wind speed and the air speed due to rotation forms a positive angle of attack of the lift force to the wing Figure 5 VERTICAL AXIS WIND TURBINES mraghebThe Arrow and Air Flow Direction To properly insert a new filter, look for the arrow! The arrow on your filter should always face the unit and away from the return air duct that carries the air that will be heated or cooled HVAC systems push the cool or warm air out and pull spent air in, recirculating the air Determining Air Flow Arrow Direction to Properly Insert a Air Flow Pressure Calculator The Gates Air Flow Pressure Calculator helps you understand your operation’s air flow issues, so you can find effective solutions to reduce maintenance, eliminate hose Air Flow Pressure Calculator Gates Corporation

SOP for Cleaning and Operation of Laminar Air Flow

67 LAF: Laminar Air Flow Get ready to use editable documents in MSWord Format View List Share Tweet Share Ankur Choudhary is India's first professional pharmaceutical blogger, author and Air flow rate data: this article defines air flow rate or cubic feet per minute (CFM) as the term is used to describe building air conditioners, heating systems, or building air movement rates We include examples of manufacturer's air flow rate or CFM data for HVAC equipment like air Air Flow Rate in HVAC Systems CFM fpm air flow speed Vertical Laminar Flow Hoods Room air (in red) enters the system from above the HEPA filter; 9999% particlefree air is forced downward toward the work surface Vertical laminar flow hoods are often chosen because they resemble, on a small scale, the design of a laminar flow Horizontal vs Vertical Laminar Flow Hoods Terra with hot combustion air in a turbulent zone usually above a perforated grate An emerging process is the parallel flow regenerative(PR) lime kiln ( Parson 1988) This process combines two advantages First , optimum heating conditions for lime calcining are achieved by cocurrent flow OPERATIONS STRATEGIES FOR VERTICAL SHAFT LIME KILNSMill motor speed Classifier speed Material temperature Mill air flow Mill fan speed Material moisture Mill differential pressure Water injection Mixture composition Product transport volume Grinding aid injection Composition of raw material Temperature after the mill Hot gas Grinding roller wear Mill vibrations Fresh air PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

Horizontal vs Upflow vs Downflow Furnace Guide

How to Compare a Horizontal vs Vertical Furnace This is the primary distinction between furnace types A vertical furnace, which can be an upflow or downflow furnace, is installed upright in an closet or basement Horizontal Upright or Vertical Installation This is done in either of two ways: downflow and upflow When you talk about the flow, you refer to the direction of air as it passes through the air handler or furnace When the furnace is installed, vertical and upflow, cold air moves in from the bottom while warm air What is the Difference between Vertical and Horizontal