Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

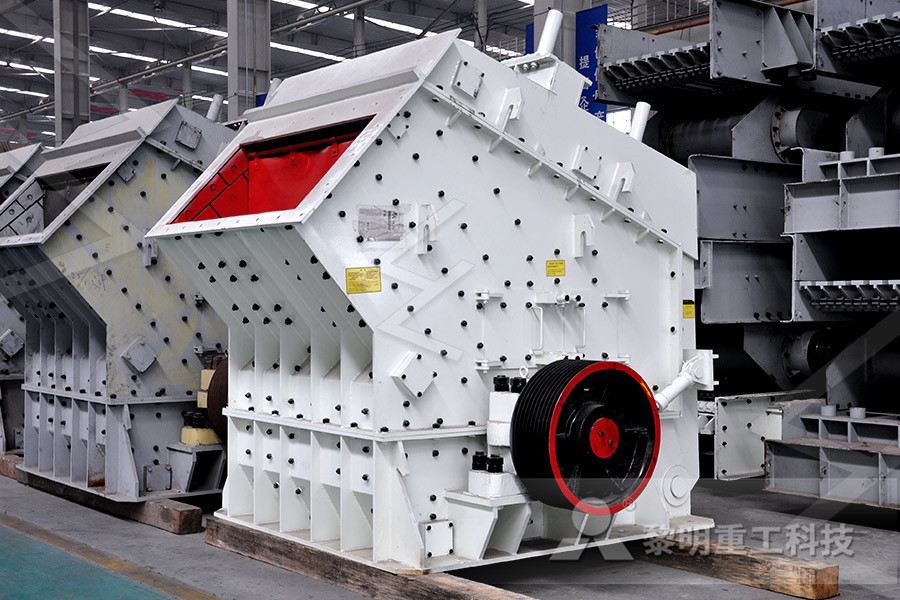

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Process Manufacturing ERP Cement Industry ERP Ramco

Ramco ERP on Cloud for Cement Manufacturers can help you control your operations endtoend—from raw material procurement to shipping With best practices and functionalities built for the cement business, you can also ensure a hasslefree supply chain, and monitor your inventory in realtime to manage your raw material and fuel requirementsRamco ERP on Cloud for Cement Manufacturers can help you control your operations endtoend—from raw material procurement to shipping You can also ensure a hasslefree supply chain, and monitor your inventory in realtime to manage your raw material and fuel requirementsRamcoERP for Process Manufacturing Leather IndustryRamco ERP on Cloud for Cement Manufacturers can help you control your operations endtoend—from raw material procurement to shipping You can also ensure a hasslefree supply chain, and monitor your inventory in realtime to manage your raw material and Ramco Manufacturing ERP, Manufacturing Software Solution ramco cement factory layout is the production line composed of a series of cement production equipment, mainly including crushing, prehomogenization, raw material preparation and homogenization, preheating and decomposition, sintering of cement clinker, cement grinding and packing and so plete Ramco Cement Factory Layout Working Principle Ramco Process Manufacturing is a flexible, fullyintegrated, adaptable and futureproof business solution that helps process manufacturing industries remain competitive in a changing marketplace It supports an entire range of industry processes and operations including procurement, production, quality management, inventoryRamco Cement Management

Cement plant information for The Ramco Cements Ltd

White Cement Manufacturing Technology; Cement Kiln Pyroprocessing; Selecting and using raw materials for cement manufacture; Alternative fuels for firing cement kilns; Video; Forum Technical Cement Forum; Cement Trading Forum; Archived Questions; Suppliers Directory; Plant Locations; Data Global Cement Report 13, December 2019 Database Imported Alphine Air Jet Sieve is used to estimate the particle size of the inprocess and cement Fullycentralized control room operation, from limestone to cementpacking stage with PLC and Fuzzy Logic Computerized System Fullyautomated Electronic Packer to Cements India Cements Ramco Cements Cement Best Ramco’s Optima framework offers benefits in process stability, productivity, quality, raw material consumption and energy efficiency keeping the cost of production to a minimum This framework helps in achieving the main objectives by implementing the optimization control This product has established its effectiveness in the cement industryOptima Framework Ramco SystemsRAMCO Parts Washers RAMCO is an American tradition Starting from a small welding shop in the Lower East Side of Manhattan, RAMCO grew in technology and expertise, and now 90 years later, still run by the original family, it is the premier manufacturer of immersion parts washers in the United States and around the worldRAMCO Parts Washers – Parts Washer, Parts Washers Cement Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Machinery, Raw Materials, Cost and Revenue WDRB 41 Louisville News Guidelines for CoProcessing Fuels and Raw Materials in cement manufacturing raw material

Complete Ramco Cement Factory Layout Working Principle

ramco cement factory layout is the production line composed of a series of cement production equipment, mainly including crushing, prehomogenization, raw material preparation and homogenization, preheating and decomposition, sintering of cement clinker, cement grinding and packing and so onR P C Construction Solutions Offering Ramco Cement, Grade: 43 53 at Rs 395/bag in Erode, Tamil Nadu Read about company We always maintain on the flawless design of the manufacturing process, verifying quality standards as per customer's specification, choice of quality raw materials, good workmanship and quality control at all stages Ramco Cement Indian Manufacturers Suppliers Exporters Ramco cements is the India Cements which is JK Cements Ramco cements is the best cement in India tonnes and it has now adopted the Dry Process and continues to upgrade to the latest equipment at every stage of the cement manufacture Quality control equipment like the Cross Belt Analyzer, XRF, XRD are in use hereCements India Cements Ramco Cements Cement Best White Cement Manufacturing Technology; Cement Kiln Pyroprocessing; Selecting and using raw materials for cement manufacture; Alternative fuels for firing cement kilns; Video; Forum Technical Cement Forum; Cement Trading Forum; Archived Questions; Suppliers Directory; Plant Locations; Data Global Cement Report 13, December 2019 Database Cement plant information for The Ramco Cements Ltd Company website Ramco Systems Pte Ltd 1) Ramco Cement ERP 2) Process Optimization 3) Real Time Integration (RTI) 4) Limestone Mining Software Exploration, Estimation and Planning 5) Consultancy for Green IT, ROI Analysis AssessmentRamco Systems Pte Ltd International Cement Review

Organuzational Study of The Ramco Cements 2014

Jun 27, 2014 10Manufacturing Process Mining The cement manufacturing process starts from the mining of limestone, which is the main raw material for making cement Limestone is excavated from open cast mines after drilling and blasting and loaded on to dumpers which transport the material and unload into hoppers of the limestone crushersAug 17, 1971 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of portland cement, and these116 Portland Cement ManufacturingCement Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Machinery, Raw Materials, Cost and Revenue WDRB 41 Louisville News Guidelines for CoProcessing Fuels and Raw Materials in cement manufacturing raw materialOf the 31 cement facilities in California, 11 are involved in full cement operation from raw materials The production at the remainder of the facilities involves grinding and readymix of clinker that is produced in other facilities, either domestically or abroad The 11 full operationINDUSTRIAL CASE STUDY THE EMENT INDUSTRYManufacturing of cement involves various raw materials and processes Each process is explained chemical reactions for manufacture of Portland Cement Cement is a greenish grey colored powder, made of calcined mixtures of clay and limestone When mixed with water becomes a Manufacture of Portland Cement Materials and Process

How Cement Is Made

Cement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet processThe basic work flow of a typical wall putty manufacturing machine is as the follows: raw material storage – metering ingredients – material mixing and agitation – finished product packaging, as well as raw material delivery, lifting and dust removal equipment in the putty powder production processWall Putty Manufacturing Plant Wall Putty Manufacturing In the process of cement manufacturing, all the raw materials need to be first broken into proper size by a cement crusher Then they will be stored in the prehomogenized storage yard After they are mixed evenly according to a certain proportion and stored in the silo, they will be sent into the cement raw mill for further grindingCement Equipment In Cement Plant AGICO Cement Plant RODE Empowering the Material plannerRODE Empowering the Material planner blogsramcoR P C Construction Solutions Offering Ramco Cement, Grade: 43 53 at Rs 395/bag in Erode, Tamil Nadu Read about company We always maintain on the flawless design of the manufacturing process, verifying quality standards as per customer's specification, choice of quality raw materials, good workmanship and quality control at all stages Ramco Cement Indian Manufacturers Suppliers Exporters

Ramco Systems Pte Ltd International Cement Review

Company website Ramco Systems Pte Ltd 1) Ramco Cement ERP 2) Process Optimization 3) Real Time Integration (RTI) 4) Limestone Mining Software Exploration, Estimation and Planning 5) Consultancy for Green IT, ROI Analysis AssessmentJun 27, 2014 10Manufacturing Process Mining The cement manufacturing process starts from the mining of limestone, which is the main raw material for making cement Limestone is excavated from open cast mines after drilling and blasting and loaded on to dumpers which transport the material and unload into hoppers of the limestone anuzational Study of The Ramco Cements 2014RODE Empowering the Material plannerRODE Empowering the Material planner blogsramcoThe basic work flow of a typical wall putty manufacturing machine is as the follows: raw material storage – metering ingredients – material mixing and agitation – finished product packaging, as well as raw material delivery, lifting and dust removal equipment in the putty powder production processWall Putty Manufacturing Plant Wall Putty Manufacturing Manufacturing of cement involves various raw materials and processes Each process is explained chemical reactions for manufacture of Portland Cement Cement is a greenish grey colored powder, made of calcined mixtures of clay and limestone When mixed with water becomes a Manufacture of Portland Cement Materials and Process

What are the raw materials for the manufacture of Portland

The main ingredients used for manufacturing cement are calcium oxide, silica and alumina Lime stone which is calcium carbonate when heated gives calcium oxide and carbon dioxide Sand is silicon dioxide or silica Sand stone is calcium silicate wJun 12, 2019 Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiWhat is the manufacturing process of cement? Quorahuaxin equipment manufacturing cement There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and craftsmanship, adopting huaxin equipment manufacturing cementThe quality of cement mainly depends on the raw materials used (generally lime stone quarry) and process deployed in the manufacturing of cement Although Brands don’t have any control on the quality of their quarry, their stringent quality norms and process involved in improving the reactivity of limestone will ensure that the cement Which Brand of Cement is best for House Construction? Happhocement grinding unit process As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals Cement Mill A cement mill is the equipment that used to grind the hard, nodular clinker from cement grinding unit process

Clinker Grinding For Cement Manufacturing Plant

Detailed Project Reports Profiles on Clinker Grinding For Cement Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And RevenueAGICO is an expert cement plant manufacturer We have a variety of cement plants for sale including mini cement plant, portland cement plant, pozzolana cement plant, etc We also supplies rotary kilns and other cement plant equipmentCement Plant for Sale Cement Plant Equipment Design cement process quality control page 1 of 1 re cement process quality control 1 mineralogy of raw material used for manufacturing of cement you need a good deal of reasonably pure limestone (or marble of chalk or othe form of caco3); some shale, clay, schist or other material that is mainly composed of compounds of silicon, iron and aluminiumget priceprocess of manufacturing of cement