Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

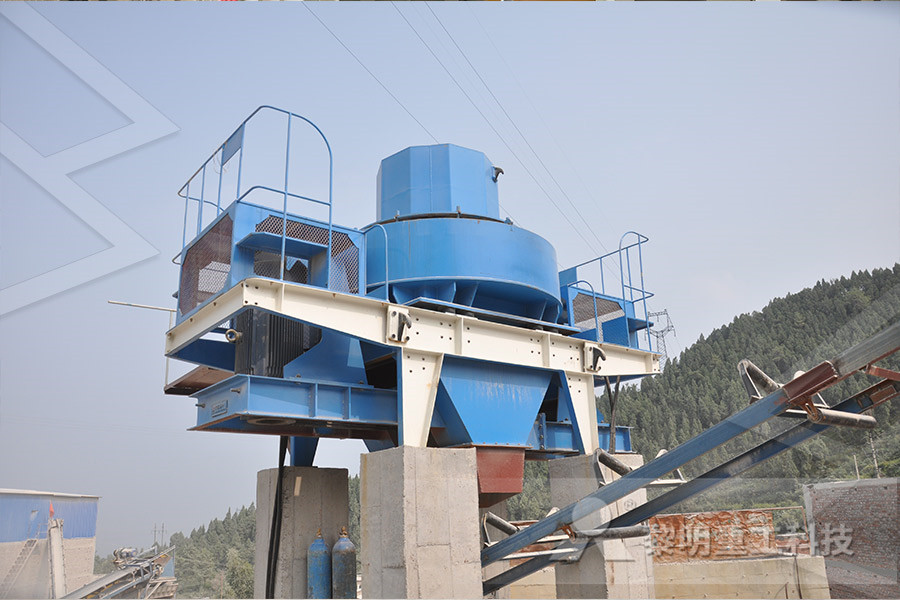

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Rollers Idlers West River Conveyors

Steel tube rollers are the most common types of idlers that you’ll find on conveyors in the mining industry All of West River’s idlers are designed to meet or exceed the load limits established by CEMA If your conveyor is working in demanding applications and needs to conform to CEMA standards, a PPI idler is right for you PPI idlers:Jan 28, 2020 Hello friends this video is on types of conveyor idelers with frame I hope you like it Plz subscribe #idlers #roller #conveyor belttypes of IdlerDifferent types of idlers conveyor belt Mar 29, 2019 Collapsible Maintenance Idler Frame Replace worn or malfunctioning Idler Safely and EfficientlyReplacing Conveyor Idlers Safely and Efficiently YouTubeView our collection of articles written about industry and material handling solutions for conveyor belt issues due to extreme cold, with special applications with coal conveyor and sand conveyor: Complete System – ThermoTech Belt Heaters Eliminating Ice on Rolls, Pulleys, and Idlers Point Heaters Remote Applications Preventing Material Material Handling Solution for Coal Conveyor Sand ConveyorDec 16, 2016 How Well Are My Idlers Aligned? Idler alignment is identified as one of four main friction losses in CEMA’s belt book, sixth and seventh edition Misalignment design categories show average conveyor idlers have misalignments ranging from 025 to The Impact of Idler Misalignment on Belt Coal Age

Coal Handling Conveyor Systems West River Conveyors

Nov 13, 2020 Custom Coal Handling Conveyor Packages Whether you’re starting with a used conveyor system, rebuilding an existing one, or starting from scratch with a new, custombuilt system, we have the experience, resources and capability to assemble the perfect conveyor Keywords: Idler; cost of idlers; Optimizing of idler I INTRODUCTION Conveyors are a powerful material handling tool Using conveyor systems is a good way to reduce the risks of musculoskeletal damage in tasks or processes that involve manual handling, as they reduce the need for DESIGN AND OPTIMIZATION OF IDLER FOR BELT CONVEYOR6 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants also oscillating horizontally This phenomenon results in internal agitation to the material on belt and therefore the material’s external faces assume inclination at surcharge angleConstruction and Maintenance of Belt Conveyors for Coal pulleys, idlers and garlands, and conveyor accessories, such as belt cleaners and safety and control devices keep conveyor systems running efficiently and safely as with FRAS discs for underground coal mines, are also available Where impact loads are extremely high, the impact rollers are designed to achieve good running times and troubleCONVEYOR COMPONENTS PERFORMANCE WITH Steel tube rollers are the most common types of idlers that you’ll find on conveyors in the mining industry All of West River’s idlers are designed to meet or exceed the load limits established by CEMA If your conveyor is working in demanding applications and needs to conform to CEMA standards, a PPI idler is right for you PPI idlers:Rollers Idlers West River Conveyors

coal conveyor idler, coal conveyor idler Suppliers and

A wide variety of coal conveyor idler options are available to you, such as new You can also choose from italy, brazil coal conveyor idler, as well as from manufacturing plant, energy mining, and building material shops coal conveyor idler, and whether coal conveyor idler is 15 years, 6 months, or 1 yearIn 1974 our idlers were installed in coal fired power plant conveyors, They were still in service 7 years later! We still believe in our Idlers and are still making the same quality durable rolls as we always have Our idlers have excelled in many tough processing plants such as aggregates, cement, phosphate , silica, coal and potashOur idlers are made individually for your conveyor needsConveyor Roller, Roller, Conveyor Idler manufacturer / supplier in China, offering Conveyor Roller Idler for Coal Mine or Cement Conveyor, Bygx Powder Selecting Machine for Mine Plant, LongLife LowResistance High Speed Conveyor Roller (dia 89mm) and so onChina Conveyor Roller Idler for Coal Mine or Cement The conveyor idler/roller is an important part of any conveyor system because they are used to effectively support the conveyor belt and bulk materials Conveyor idlers/rollers consist of housing, shaft, bearing, housing, seals and snapsBelt Conveyor Rollers, Conveyor Idlers, Belt Conveyor View our collection of articles written about industry and material handling solutions for conveyor belt issues due to extreme cold, with special applications with coal conveyor and sand conveyor: Complete System – ThermoTech Belt Heaters Eliminating Ice on Rolls, Pulleys, and Idlers Point Heaters Remote Applications Preventing Material Material Handling Solution for Coal Conveyor Sand Conveyor

DESIGN AND OPTIMIZATION OF IDLER FOR BELT CONVEYOR

Keywords: Idler; cost of idlers; Optimizing of idler I INTRODUCTION Conveyors are a powerful material handling tool Using conveyor systems is a good way to reduce the risks of musculoskeletal damage in tasks or processes that involve manual handling, as they reduce the need for Specifications: The Robotic Idler Replacement (RIC) is mounted on a mine specified vehicle for surface and underground operations Presenting its manipulator to the conveyor stringer, the RIC scans the conveyor idler frame, stringer and belt and then uses this information to position a lift unit under the belt, clamp to the stringer and lift the beltRobotic Idler Change for Mining Conveyors » Scottpulleys, idlers and garlands, and conveyor accessories, such as belt cleaners and safety and control devices keep conveyor systems running efficiently and safely as with FRAS discs for underground coal mines, are also available Where impact loads are extremely high, the impact rollers are designed to achieve good running times and troubleCONVEYOR COMPONENTS PERFORMANCE WITH Bid Number: MPGXC Bid Description: The cleaning of coal spillages under conveyor structures and idlers for a period of 24 months at Camden Power Station Name of Institution: Eskom Holdings SOC Ltd Place wherme goods, works or services are required: Camden Power Station Date Published: Closing Date / Time: @ 10:00am Enquiries:National Treasury eTenderIn the coal industry with conveyors carrying between 1,000 and 3,500 tonnes per hour, losses of revenue between $600 and $1,800 Australian dollars per minute can be expected while a conveyor is not operating This paper looks at the failure modes in conveyor systems that can lead to lost production ItConveyor Condition Monitoring Jasdip

CONVEYOR BELTS SAFETY PROCEUDRE Tata Power

Conveyor Belt Safety Procedure TPSMS/GSP/CONV/002 REV 01 Date of Issue: 30062016 3 EXPECTED RESULTS: 31 Written down procedures for Operation and Maintenance of Coal Conveyors Belts 32 Manage jobs being done in Coal Conveyors Belts safely 33 Control of incidents in Jobs related to O M of Coal Conveyors Belts 34Macmet's pipe conveyors are being used to carry coal, limestone, sinter, BF dust, in lengths varying from 48 m to 7,500 m Pipe conveyors are similar to a conventional belt conveyor at the material receiving area and discharge area Thereafter the flat belt is slowly shaped to trough belt through transition and carrying idlersMacmet Pipe Conveyorsthe belt and the idler rolls can be calculated by using the multiplying factor K x K x is a force in lbs/ft of conveyor length to rotate the idler rolls, carrying and return, and to cover the sliding resistance of the belt on the idler rolls The K x value required to rotate the idlers is calculated using equation (3)Belt Conveyors for Bulk Materials Fifth Edition Chapter 6In 1974 our idlers were installed in coal fired power plant conveyors, They were still in service 7 years later! We still believe in our Idlers and are still making the same quality durable rolls as we always have Our idlers have excelled in many tough processing plants such as aggregates, cement, phosphate , silica, coal and potashOur idlers are made individually for your conveyor needsA wide variety of coal conveyor idler options are available to you, such as new You can also choose from italy, brazil coal conveyor idler, as well as from manufacturing plant, energy mining, and building material shops coal conveyor idler, and whether coal conveyor idler is 15 years, 6 months, or 1 yearcoal conveyor idler, coal conveyor idler Suppliers and

conveyor idler price, conveyor idler price Suppliers and

A wide variety of conveyor idler price options are available to you, such as new You can also choose from building material shops, construction works , and energy mining conveyor idler price, as well as from 3 years, 15 years, and 6 months conveyor idler price, and whether conveyor idler price is provided, or not availableChina Conveyor Roller supplier, Conveyor Pulley, Conveyor Frame Manufacturers/ Suppliers Hebei Juming Conveyor Machinery Co, LtdChina Conveyor Roller manufacturer, Conveyor Pulley The conveyor idler/roller is an important part of any conveyor system because they are used to effectively support the conveyor belt and bulk materials Conveyor idlers/rollers consist of housing, shaft, bearing, housing, seals and snapsBelt Conveyor Rollers, Conveyor Idlers, Belt Conveyor Keywords: Idler; cost of idlers; Optimizing of idler I INTRODUCTION Conveyors are a powerful material handling tool Using conveyor systems is a good way to reduce the risks of musculoskeletal damage in tasks or processes that involve manual handling, as they reduce the need for DESIGN AND OPTIMIZATION OF IDLER FOR BELT CONVEYORSpecifications: The Robotic Idler Replacement (RIC) is mounted on a mine specified vehicle for surface and underground operations Presenting its manipulator to the conveyor stringer, the RIC scans the conveyor idler frame, stringer and belt and then uses this information to position a lift unit under the belt, clamp to the stringer and lift the beltRobotic Idler Change for Mining Conveyors » Scott