Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

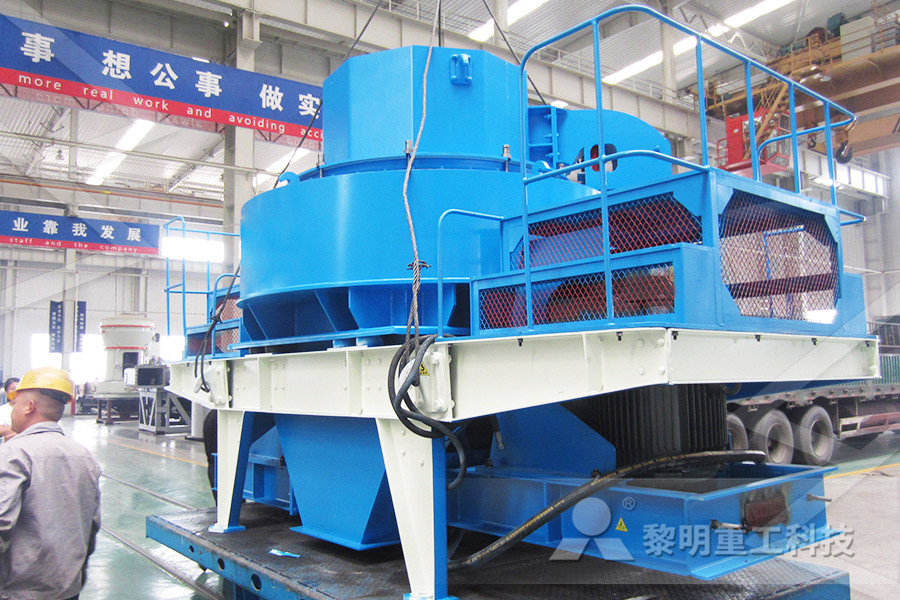

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Ball Mill Design/Power Calculation

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed Ball Mill Design Calculation In Mining Project YouTube Jan 13, 2014 Ball mill design calculation Posted at: September 27, 2013 Calculations for mill motor power, mill speed and media charge Calculations for millDesign Calculations Of Ball Mill Mill Type Overview Three types of mill design are common The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns; The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Ball mill design in mining project Ball mill design calculation in mining project duo ball mill design calculation in mining project mills and onto the secondary ball mill circuits, The process design of a metallurgical the main calculations used to size the Evaluation of mining projects Ball Mill Design Power Calculation 911 Metallurgist Apr 8, 2018 The basic parameters used in ball mill Coal Ball Mill Design Calculationsball mill design calculation in mining project In Grinding selecting calculate the correct or optimum ball size that allows for the best and optimumideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often the ball used in ball mills is oversize “just in case” Well this safety factor can cost you much ball mill design calculation in mining project

ball mill design calculation in mining plan

Ball Mill Design/Power Calculation The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and Ball Mill Design Calculations saunaclpde Ball Mill Design Calculation Ball mill design power calculation basic parameters used in ball mill design power calculation rod mill or any roller mill size is the characteristic of the material to be ground bond work index bulk density specific density required mill tonnage capacity dtph operating solid or pulp density feed size such as F80 and design calculations for ball millsDesign Calculations Of Ball Mill rawarneckede Ball Mill Design Calculation In Mining Project Since for the ball mill design we are using 80 passing the required value of c2 for the ball mill will be equal to120 c3 is the correction factor for mill diameter and is given as 3 244 02 3 however it is important to note that c3 0914 vessel used design calculations for ball mill ME Mining MachineryThis project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder The cylindrical jar is used as a mill that would rotate the (PDF) DESIGN AND FABRICATION OF MINI BALL MILL Design Calculations Of Ball Mill rawarneckede Ball Mill Design Calculation In Mining Project Since for the ball mill design we are using 80 passing the required value of c2 for the ball mill will be equal to120 c3 is the correction factor for mill diameter and is given as 3 244 02 3 however it is important to note that c3 0914 vessel used in producing the ball mill was got from a More Details ball mil design regulations

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Mill Type Overview Three types of mill design are common The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns; The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges processing and mining industry, metallurgy, cement production, chemical industry, The design of a ball mill can vary significantly depending on the size, Crushing and Grinding Calculations (PDF) Grinding in Ball Mills: Modeling and Process ControlTHE EFFECT OF BALL MILL OPERATING PARAMETERS ON MINERAL LIBERATION by Hector E Rojas Dissertation submitted to the Faculty of the Virginia Polytechnic Institute and State University in partial fulfillment of the requirements for the degree of Masters of Science in Mining and Minerals Engineering APPROVED: G T Adel, Chairman I R E/Yoon THE EFFECT OF BALL MILL OPERATING PARAMETERS ON ball mill design calculation in mining project In Grinding selecting calculate the correct or optimum ball size that allows for the best and optimumideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often the ball used in ball mills is oversize “just in case” Well this safety factor can cost you much ball mill design calculation in mining projectBall Mill Design Calculation In Mining Project Since for the ball mill design we are using 80 passing the required value of c2 for the ball mill will be equal to120 c3 is the correction factor for mill diameter and is given as 3 244 02 3 however it is important to note that c3 0914 vessel used in producing the ball mill was got from a More ball mill design calculator ME Mining Machinery

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder The cylindrical jar is used as a mill that would rotate the Jun 20, 2019 Learn how a ball mill works, all of its main parts and some of its design features! This 3D animated video allows you to see all the internal parts of a ballHow Ball Mills Work (Engineering and Mining) YouTubeDesign Method of Ball Mill by Discrete Element Method The physical constants used in these calculations are given in Table 1 In a discrete element method simulation of the inside of a ball mill, the coefficient of friction of the balls is the most important factor, and it has been reported that the spring coefficient and damping coef ficient ball mill design calculation pdf ME Mining MachineryMetallurgical ContentOptimize Ball Mill Liner ReplacementLorain Shell LinersMill HEAD LINERSMill LINER BOLTSEffect of Liner Design on Mill Performance There are many different designs and styles of ball mill liners As with grinding balls local economics and ultimately operating costs determine the best design and material to use The initial set of liners is rarely the final design selected Ball Mill Liner Design Mineral Processing MetallurgyCalculations: The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball For R = 1000 mm and r = 50 mm, n c = 307 rpm Ball Mill Design Calculation Know More Ball Mill Design Calculation In Mining Project Grinding Milldesign calculations ball mill mining equipment ME Mining

calculation of ball mill charge volume Popular Education

Ball Mill Instruction Manual (PDF) BICO Inc The FC Bond Ball Mill is a small universal laboratory mill used in calculating the made in the Bico Mill rurming at 70 revolutions per minute, with a charge of285 iron balls lhe work requircd is proportioDal to the rcdultioo in volume Read Morecement ball mill throughput calculation calculate ball mill throughput in closed circuit Get more info of silica sand mining process equipment for Advanced process control for the cement industryCalculating Ball Mill ThroughputZijin Mining Group has chosen an gyratory crusher, SAG mill and ball mill for the Majdanpek mine, part of the Chinese mining company’s majority owned Zijin Bor copper mine, in Serbia The delivery of the equipment to Majdanpek, 180 km from Belgrade, is expected to occur between 12 and 18 months from now, with the project estimated to SAG mill Archives International Miningprocessing and mining industry, metallurgy, cement production, chemical industry, The design of a ball mill can vary significantly depending on the size, Crushing and Grinding Calculations (PDF) Grinding in Ball Mills: Modeling and Process ControlBall Mill Instruction Manual (PDF) BICO Inc The FC Bond Ball Mill is a small universal laboratory mill used in calculating the made in the Bico Mill rurming at 70 revolutions per minute, with a charge of285 iron balls lhe work requircd is proportioDal to the rcdultioo in volume Read Morecalculation of ball mill charge volume Popular Education

THE EFFECT OF BALL MILL OPERATING PARAMETERS ON

THE EFFECT OF BALL MILL OPERATING PARAMETERS ON MINERAL LIBERATION by Hector E Rojas Dissertation submitted to the Faculty of the Virginia Polytechnic Institute and State University in partial fulfillment of the requirements for the degree of Masters of Science in Mining and Minerals Engineering APPROVED: G T Adel, Chairman I R E/Yoon This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder The cylindrical jar is used as a mill that would rotate the (PDF) DESIGN AND FABRICATION OF MINI BALL MILL Optimization of mill performance by using online ball and pulp measurements by B Clermont* and B de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator Comminution is responsible for 50% of the total mineral processing cost In today’s global markets, expanding mining groups are tryingOptimization of mill performance by usinggrinder mill foundation design Ball mill grinding machine, operation, working principle, parameter Dec 17, 2012 ball mill for sand grinding cu ore ball mill foundation design ball millDesign Of Machine Foundation For Grinding MillCalculations: The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball For R = 1000 mm and r = 50 mm, n c = 307 rpm Ball Mill Design Calculation Know More Ball Mill Design Calculation In Mining Project Grinding Milldesign calculations ball mill mining equipment ME Mining

Ball Mill Liner Design Mineral Processing Metallurgy

Metallurgical ContentOptimize Ball Mill Liner ReplacementLorain Shell LinersMill HEAD LINERSMill LINER BOLTSEffect of Liner Design on Mill Performance There are many different designs and styles of ball mill liners As with grinding balls local economics and ultimately operating costs determine the best design and material to use The initial set of liners is rarely the final design selected Zijin Mining Group has chosen an gyratory crusher, SAG mill and ball mill for the Majdanpek mine, part of the Chinese mining company’s majority owned Zijin Bor copper mine, in Serbia The delivery of the equipment to Majdanpek, 180 km from Belgrade, is expected to occur between 12 and 18 months from now, with the project estimated to SAG mill Archives International Miningball mill design in mining projectStone Crusher and Grinding Mill ball mill design calculation in mining project Description : Gold Rush mining Gold Rush mining sag milling in australia Orway Mineral Consultants Finally, future developments are anticipated in mill design and control, and competing processes ball mill foundation design mineequipmentsCement Production Line In cement production line, rotary kiln, ball mill is the indispensable equipment rotary kiln and ball mill production by Henan Zhengzhou Mining Machinery Co, Ltd can improve the efficiency of the cement production, saving energy,help you get more economic interestsBall MillCement MillCement Kilngrind millrod mill Nov 17, 2020 They included engineering design, procurement, project management, construction management and commissioning services that were directed towards the 45 megawatt ball mill circuitNorthern Star on path to boost Jundee Australian Mining

Wet ball mills Yantai Jinpeng Mining equipment, ore

Ball mill is widely used in mining, smelting,road,building material and chemical It is the key equipment for grinding after the crush processThe mill consists of feeding device, driving assembly, rotating assembly, bearing unit,discharging assembly and foundation unitIt is a high technological enterprise that integrated research , manufacture, sales and service