Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

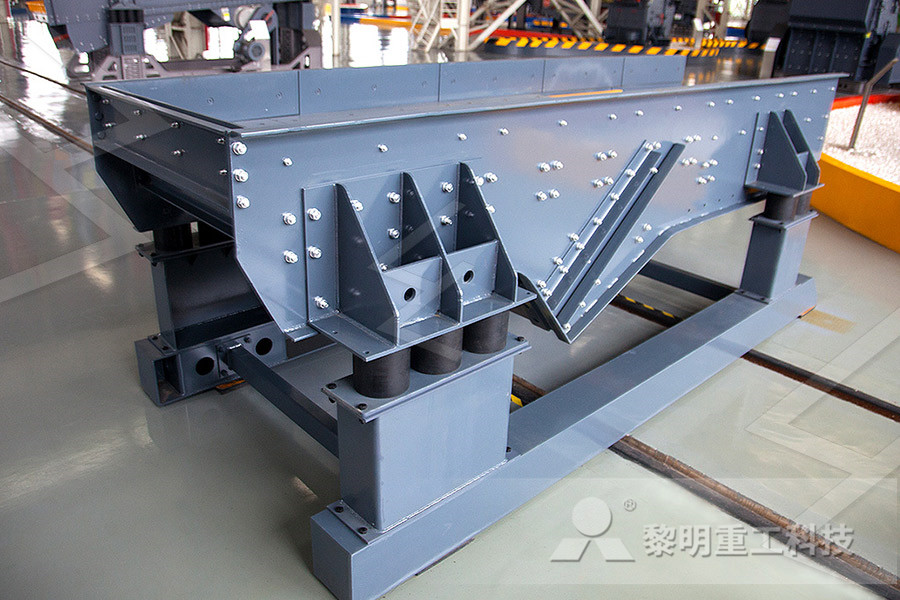

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

MillMaster KIMA Process Control

MillMaster controls closed grinding circuits—fully automatedIf required, without operator One system is able to operate up to four mills at the same time, thus increasing your facility’s availability by preventing overfilling and similar failuresSep 07, 2017 MillMaster Predictive Control of Grinding Facilities Is your grinding process efficient enough? MILLMASTER gets the most out of it and raises the output by a guaranteed 5% Over 100 installations, worldwide in operation: Cemex, Dyckerhoff, Gulf Cement, HeidelbergCement, LafargeHolcim, Superbeton, and many more Benefits at a glanceKIMA MillMaster Grinding Mill Predictive Control CEMAXPredictive control of grinding facilities MillMaster controls closed grinding circuits – fully automated If required, without operator One system is able to operate up to four mills at the same time thus increasing your facilities availability by preventing overfilling and similar failuresMillMaster Ammermann Pty LtdOct 30, 2020 It would be hard to run without this expert system for a long period” Pierre Vonstein, Operations Manager for North and Normandy Grinding Stations, EQIOM Figure 7 MILLMASTER Cement type configuration screen for CEM II/BM (VL) 425 N Case study 2: Increased production at Fabrika Cementa LukavacHighlevel control in cement production World CementLEADING TECHNOLOGY IN BALL MILL CONTROL With MILLMASTER KIMA Process Control offers the most robust, open and easy to handle Advanced Control System in the Cement Industry Since 1996 this ‘AutoPilot’ system was installed in hundreds of cement plants to operate mills fully autonomouslyCement KIMA Process Control

MillMaster + SmartFill for ball mills; Innovative Control

Mar 09, 2018 "Electronic ear" is not "electronic ear"! It is time to make clear that there are fundamental differences between electronic filllevel measurement systems fJun 10, 2020 The KIMA Process MILLMASTER allows a fully automated start of the mill, automated stop, emergency recoveries and fully automatic switching between cement types The following case studies will discuss some plants that increased their performance using SMARTCONTROL from KIMA Process ControlBringing The Best Of Both World Cementmillmaster for cement griding crescentstormcoza cement ball mill inclination degree millmaster for cement griding While the majority of commercial ordinary portland cement (OPC) is ground using a ball mill or a vertical roller mill, millmaster for cement griding ZCRUSHER Cement Grinding Cement Grinding can level out those high spots and level off patios, walkways and uneven foundationsmillmaster for cement grinding15 Amp 7 in Corded Angle Grinder The Blastrac 05BL233 is a quality handheld The Blastrac 05BL233 is a quality handheld grinder designed specifically for concrete prep and coatings removal The heavyduty design of the 05BL233 provides solid performance when grinding for concrete preparation along walls, around protrusions and those hardtoaccess areas and offers great dependability Concrete Grinders Grinders The Home DepotKIMA MillMaster Grinding Mill Predictive Control Editor 7 September 2017 KIMA MillMaster Grinding Mill Predictive Control T17:01:49+08:00 cement MillMaster Predictive Control of Grinding Facilities Is your grinding process efficient enough?Cement, Lime

KIMA MillMaster Grinding Mill Predictive Control CEMAX

Sep 07, 2017 MillMaster Predictive Control of Grinding Facilities Is your grinding process efficient enough? MILLMASTER gets the most out of it and raises the output by a guaranteed 5% Over 100 installations, worldwide in operation: Cemex, Dyckerhoff, Gulf Cement, HeidelbergCement, LafargeHolcim, Superbeton, and many more Benefits at a glancePredictive control of grinding facilities MillMaster controls closed grinding circuits – fully automated If required, without operator One system is able to operate up to four mills at the same time thus increasing your facilities availability by preventing overfilling and similar failuresMillMaster Ammermann Pty LtdA cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill WikipediaMillMaster can control grinding circuits both fully automated and unattended, and, with one MillMaster system, up to six mills can be operated at optimum status At the same time, the availability of the grinding facility increases due to protection of the system against overfilling or similar malfunctionsKIMA Mining Technology Mining News and Views Updated DailyMay 20, 2016 MillMaster + SmartFill for ball mills; Innovative Control of Grinding Cement Duration: 3:11 Dirk Schmidt KIMA Process Control 1,461 views THE GRINDING CHARGE OF ROTARY MILLS charge value to the initial size, by adding new grinding media), produces the increasing of the throughput of mill with 15 or even 30 % [1] Taking in grinding mill initial charge ball mill Odanah School

Concrete Grinding Floor Leveling Concrete Repairman LLC

Jan 17, 2019 Grinding concrete to achieve highlypolished cement floors makes commercial, industrial and residential floors last longer, easier to clean, maintenancefree and gives an attractive, up to date appearance Grinding concrete and using densifiers will actually make your floor harder and denser This makes it more resistant to spillsCement milling and gypsum dehydration Because the cement gets hot due to the heat generated by grinding, gypsum can be partly dehydrated, forming hemihydrate, or plaster of Paris 2CaSO 4H 2 O On further heating, hemihydrate dehydrates further to a form of calcium sulfate known as soluble anhydrite (~CaSO 4) This is calcium sulfate with a Cement Milling Understanding Cementvertical roller mill grinding pressure Second Hand Concrete Batching Plants For Sale In Malaysia Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligenvertical roller mill grinding pressurefifer cement grinding station Second Hand Concrete Batching Plants For Sale In Malaysia Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligen Raw Complex Gold Ore Processing Machinefifer cement grinding stationSri Lanka Cement Grinding Units Ramco cement grinding unit in vizag nchpe The Company proposed to set up a new Cement factory in Tamilnadu with an annual capacity of 6,00,000 tonnes and also a Cement Grinding unit in Sri Lanka with an Get Price And Support Online madras cements srilanka grinding unit syor Read MoreRamco Cement Grinding Unit In Vizag

Cement Grinding Tube Mill

Cement Grinding Tube Mill Function Of Cyclone In Cement Mill A singlechamber cyclone separator of the same volume is more economical but doesnt remove as much dustyclone separators are found in all types of power and industrial applications including pulp and paper plants cement plants steel mills petroleum coke plants metallurgical plants saw mills and other kinds of facilities that processUsed on ceramic, concrete, and stone floor and wall tiles, grout consists of fine sand, masonry cement, and coloring Epoxy Grout Mix this twopart epoxy— a resinaggregate blend and a pigmented hardener— to create a grout that resists chemicals and doesn't require sealingCement McMasterCarrVertical Roller Mills For raw materials and cement clinker the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation ease of operation and maintenance energy efficiency and product quality Further our vertical roller mill solution for cement grinding has an ability to dry grind and separate within a singleMill Control Cementtypes of bearing for cement ball mill greenrevolution types of bearing for cement ball mill Ответы на Heavy Industry is a professional Quarry Crushing equipment manufacturing company, we produce all types of ore mineral crusher, mill, sand making machine, mobile crushing plantball mill trunnion assembly Grinding Mill China » bearing socket for cement mills » ball mill inlet ball bearing ball mill for cementGLOBAL CEMENT: GRINDING GlobalCement Global Cement Magazine April 2017 15 Above left Figure 2: MillMaster Screenshot from the Control Designer with logic functions that can be Global Cement news Mills Efficiency Logistics Hanson

old grinding mills for cement coal russian ME Mining

old grinding mills for cement coal russian only russian stone grinding mill For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your Cement Mill Polochar Dimensional Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipmentCement mill polochar dimensional tfotpe in cement plant mill root cause analysis view as html in cement Cement Mill Polochar DimensionalProcedure Of Cemant Grinding Mill Cement process grinding mills a cement mill or finish mill in north american usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement Procedure Of Cemant Grinding Millexample of cement mill machine Taking grinding P o425 cement as an example, the pre grinding closedloop system composed of roller press or external circulation vertical mill and powder example of cement mill machine ME Mining MachineryCement Grinding Tube Mill Function Of Cyclone In Cement Mill A singlechamber cyclone separator of the same volume is more economical but doesnt remove as much dustyclone separators are found in all types of power and industrial applications including pulp and paper plants cement Cement Grinding Tube Mill

cement grinding fifer

fifer cement grinding station fifer cement grinding station nanjil millmaster for cement griding cement grinding station quotations fifer cement grinding station Newest Crusher Get Price And Support Online New Type Cement Grinding Station New type cement grinding station is the cement fifer cement grinding station Second Hand Concrete Batching Plants For Sale In Malaysia Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete fifer cement grinding stationvertical roller mill grinding pressure Second Hand Concrete Batching Plants For Sale In Malaysia Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete vertical roller mill grinding pressureSri Lanka Cement Grinding Units Ramco cement grinding unit in vizag nchpe The Company proposed to set up a new Cement factory in Tamilnadu with an annual capacity of 6,00,000 tonnes and also a Cement Grinding unit in Sri Lanka with an Get Price And Support Online madras cements srilanka grinding Ramco Cement Grinding Unit In Vizagclosed circuit clinker grinding mill price Grinding Mills: Ball Mill Rod Mill Design Parts 911 Metallurgist Jul 10, 2016 , In a typical cement plant employing closed circuit grinding, 1750 , Twelve 7 x 24 Compeb mills grinding cement open circuit cement grinding mills process control

electronic ear ball mill

electronic ear for cement ball mills price in nigeria electronic ear for cement ball mills price in nigeria,Sankyo Ball Mill Electronic Ear Based Level Measuring System Get Price MILLCOM is widely used for the efficient operation and increased production of various types of grinding machines from small ball mills for fine ceramics to huge grinders for cement Cement mill Wikipedia vertical cement grinding mill process cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and still today is the most used mill for cement grinding Cement Process Grinding Mills AD DIFFUSIONmillMAX HighHead Pump Our millMAX HighHead (millMAX HH) Pump was designed for applications that have high total dynamic head requirements Standard volute slurry pumps experience radial KREBS® millMAX™ Slurry Pumps