Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

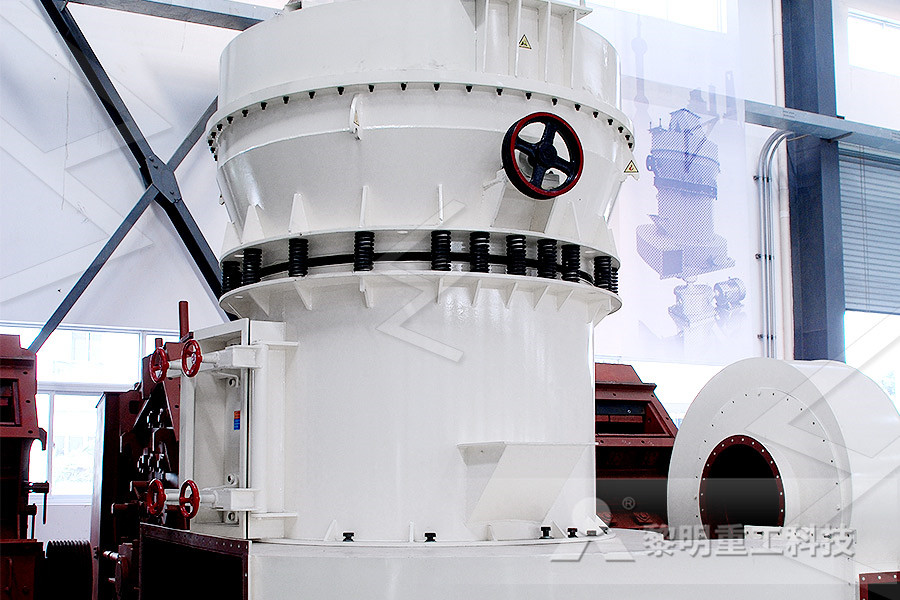

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

High Rate Thickener Outotec

High Rate Thickener Outotec® High Rate Thickener Take advantage of our pioneering thickening and clarifying methods with the Outotec High Rate Thickener, including advances such as lowprofile triangular rake arms to reduce rake torqueAltaFlo ultra highrate thickeners perform well as tailings thickeners, in CCD circuits, as concentrate thickeners, and in leaching circuits The low CAPEX economics of an AltaFlo also make it a perfect solution for dewatering nonprofit streams The heart of any thickener or clarifier is the feedwellAltaFlo™ High Rate Thickeners WesTech Engineering, IncThe HCT has been designed with a smaller footprint and higher walls than our High Rate Thickener or conventional thickeners Benefits Thickener feed system was upgraded to increase capability of your thickener, reduce tailings management costs and environmental impactHigh Compression Thickener OutotecFor example, a tailings stream in an iron ore application could be thickened to 45–50% solids Newtonian slurry in conventional or highrate thickeners Conversely, the same tailings stream could be thickened to 65–70% solids nonNewtonian suspension using a paste thickenerTailings Mineral Industry Solution WesTech Engineering, IncLike the High Rate thickener, tailings disposal, the thickener is a lways a practical and essent ial part of the flowsheet before th e filter(PDF) THICKENER DESIGN, CONTROL AND DEVELOPMENT

Design Considerations for a Tailings Disposal System E MJ

A high density thickener produces thickened tailings The difference between a high rate and a high density thickener is the underflow will not segregate—that water remains bound into the mixture A deep cone, or deep bed, thickener produces paste Both high density and deep cone thickeners depend on retention time rather than areaTo participate in the 911Metallurgist Forums, be sure to JOIN LOGIN Use Add New Topic to ask a New Question/Discussion about Thickening, Filtering or Tailings and Water OR Select a Topic that Interests you Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent) Using Add Reply allows you to Attach Images or PDF files and provide a more complete input Use Add Comment How to Size a HighRate Thickener Thickening, Filtering 2017 high capacity tailing thickener for copper mining About 53% of these are mining thickener, 5% are pumps, and 1% are sand washer A wide variety of tailing thickener options are available to you, such as free samples There are 433 tailing thickener suppliers, mainly located in Asia2017 high capacity tailing thickener for copper mining GLOBAL LEADER IN HIGHRATE THICKENERS 100+ times smaller footprint with comparable flocculant consumption to conventional rake thickeners and no moving parts Feed densities up to 55 % discharging underflow at 70 % (solution could be halved) – no other thickener can compareMagra Global leader in HighRate ThickenersHighRate Thickener Watch to learn how McLanahan HighRate Thickeners can help to reduce settling ponds or tailings storage facilities How Can A Thickener Help Your Operation? At McLanahan, our goal is to make sure that your operation is running properly and efficiently We understand that operations differ and the needs of one are not always Thickeners McLanahan

Control of a High Rate Thickener on Gold Plant Tailings

The use of High Rate Thickeners has gained wide acceptance in the mineral treatment industries The design of these units is characterized by an efficient deaeration and flocculation chamber, and introduction of the flocculated feed solids into a preformed floc bed zone By these means the settling process is accelerated and consequently High Rate ThickenersHigh Rate Sludge Tailing Mining Thickener For Sale , Find Complete Details about High Rate Sludge Tailing Mining Thickener For Sale,Thickener,Sludge Thickener,Mining Thickener from Mining Thickener Supplier or ManufacturerZhengzhou Hengxing Heavy Equipment Co, LtdHigh Rate Sludge Tailing Mining Thickener For Sale Buy The HighRate thickeners became popular in the mid 1980's and are relatively newcomers to the sedimentation line of equipment As already discussed previously Thickenersare a major component in a plant layout and occupy large spaces which may be saved by introducing highrate machines Furthermore, they are normallyHigh Rate Thickeners Solid Liquid SeparationEIMCOKCP Thickeners are manufactured for heavy duty Concentrates, tailings and fine application and three basic configurations: Bridge mounted, Column mounted and Traction type and sizes up to 500 feet diameter are available Optional lifting devices for either design offer additional operational flexibility EIMCO KCP HIGH RATE THICKENERSThickener EKCPA high density thickener produces thickened tailings The difference between a high rate and a high density thickener is the underflow will not segregate—that water remains bound into the mixture A deep cone, or deep bed, thickener produces paste Both high density and deep cone thickeners depend on retention time rather than areaDesign Considerations for a Tailings Disposal System E MJ

Thickeners McLanahan

HighRate Thickeners are used by the aggregate and mining industries, as well as environmental contractors, to recover approximately 85% of water for reuse This highlevel of water recovery keeps water consumption at sustainable levels, as well as drastically reduces Thickened and Paste Tailings Pipeline System Design Procedure – Part 1, Page 6 33 Slump tests 331 Standard 12” slump cone A popular the method for obtaining an indication of flow behaviour is the standard 12” (305 mm tall) slumpThickenedandPasteTailingsPipelineSystems: Design Procedure The thickening process is the primary method of producing high solids slurries for the minerals industry Thickener outputs can accommodate a range of tailings disposal options from low yield(PDF) Understanding the Thickening ProcessOutotec has a comprehensive range of pilot plant units for conventional settling, high rate thickening and/or clarifying, high compression and also paste thickening A feed rate of 18m3/h (44352 US gpm) of pulp is required for the pilot plant thickener/clarifierOutotec Thickening technologies2017 high capacity tailing thickener for copper mining About 53% of these are mining thickener, 5% are pumps, and 1% are sand washer A wide variety of tailing thickener options are available to you, such as free samples There are 433 tailing thickener suppliers, mainly located in Asia2017 high capacity tailing thickener for copper mining

Tailingsfo Laboratory and Pilot Plant Testing Programmes

Pilot Thickening Trials: Limit Testing – Onsite pilot thickener trials using a truck mounted or small scale thickener (typically up to 5 tonnes per day) operating for a short period of time, primarily to determine limitations of thickening an existing tailings feed These styles of trials are driven by thickener vendors to adopt high rate, high compression or paste thickening technologyHighRate Thickeners provide immediately reuseable process water and recover approximately 85% of the water from an effluent feed This high level of water recovery keeps water consumption at sustainable levels, as well as drastically reduces the slurry volume reporting to tailings damWater Recovery High Rate Thickener Lincom GroupHighRate Thickener Watch to learn how McLanahan HighRate Thickeners can help to reduce settling ponds or tailings storage facilities How Can A Thickener Help Your Operation? At Thickeners McLanahanThe use of High Rate Thickeners has gained wide acceptance in the mineral treatment industries The design of these units is characterized by an efficient deaeration and flocculation chamber, and introduction of the flocculated feed solids into a preformed floc bed zone By these means the settling process is accelerated and consequently High Rate ThickenersControl of a High Rate Thickener on Gold Plant Tailings High Rate Sludge Tailing Mining Thickener For Sale , Find Complete Details about High Rate Sludge Tailing Mining Thickener For Sale,Thickener,Sludge Thickener,Mining Thickener from Mining Thickener High Rate Sludge Tailing Mining Thickener For Sale Buy

High Density Thickener – Amstar Corporation

High Density Thickener Amstar’s high density Thickener offers the advantages of paste and thickened tailings for very large tonnages Water savings and tailings deposition can be accomplished with fewer tanks and at a lower capital cost than with the equivalent number of Deep Bed paste thickenersHighRate Thickeners provide immediately reuseable process water and recover approximately 85% of the water from an effluent feed This high level of water recovery keeps water consumption at sustainable levels, as well as drastically reduces the slurry volume reporting to tailings Water Recovery High Rate Thickener Lincom GroupEIMCOKCP Thickeners are manufactured for heavy duty Concentrates, tailings and fine application and three basic configurations: Bridge mounted, Column mounted and Traction type and sizes up to 500 feet diameter are available Optional lifting devices for either design offer additional operational flexibility EIMCO KCP HIGH RATE THICKENERSThickener EKCP6 Advantages of Efficient Improved Thickener The thickener is one of the indispensable equipment of each largescale beneficiation plant, which is suitable for the dewatering treatment of concentrate and tailings in the beneficiation plantHowever, with the continuous improvement of mineral processing requirements, the disadvantages of traditional thickeners Thickener, Mining Thickener, Tailings Thickener Miningpedia“The plant generates around 10 Mt of tailings a year and, thanks to the Outotec ACT Thickener Optimizer, the paste thickeners can consistently run with a high and stable underflow solids content of 6668%, regardless of challenging mineralogy and tailings feedrate tailings thickening Archives International Mining

Tailingsfo Laboratory and Pilot Plant Testing Programmes

Pilot Thickening Trials: Limit Testing – Onsite pilot thickener trials using a truck mounted or small scale thickener (typically up to 5 tonnes per day) operating for a short period of time, primarily to determine limitations of thickening an existing tailings feed These styles of trials are driven by thickener vendors to adopt high rate, high Thickened and Paste Tailings Pipeline System Design Procedure – Part 1, Page 6 33 Slump tests 331 Standard 12” slump cone A popular the method for obtaining an indication of flow behaviour is ThickenedandPasteTailingsPipelineSystems: Design Procedure At times, these multiple thickeners were difficult to operate, leading to inefficiencies in water recovery and quality The development of HighRate Thickeners (HRT) has resulted in improved settling properties and HRTs usually operate at significantly higher solids loadings (≤ 12 t/m2h) when compared to conventional thickeners Carmen Copper – A Sustainable Approach to Tailings Our thickened tailings solution uses a highrate or highdensity thickener, resulting in 50 to 65% solids, to recover water in tailings prior to disposal With this option, you will recover higher volumes of water Tailings solutions for all mine conditionsThe water balance of this site is provided in Table 1 The iron recovery process sends a tailings stream to the first thickener with about 8,000 m3/h water (about 9 wt% solids) The high rate thickener produces 45~50 wt% solids and recovers about 90% of this water The paste thickener Paste and thickened tailings water benefits case studies

Improve Clarifier and Thickener Design and Operation

The thickener area is also required for this calculation Guess the thickener area for the first iteration Several iterations of area may be required to achieve a practical thickener size and pumping rate For a circular thickener