Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

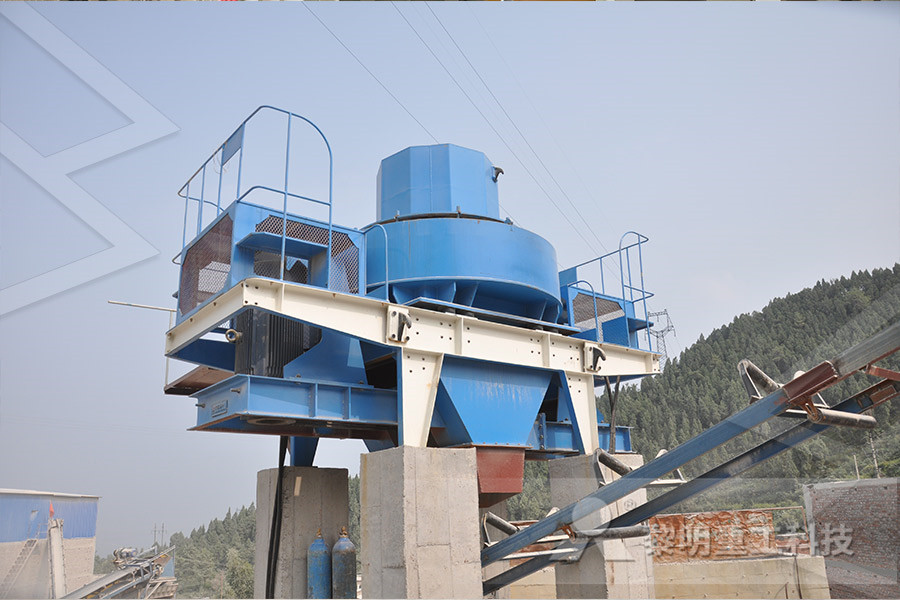

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

The Mill Spring Foundation GuideStar Profile

The Mill Spring Foundation lock Unlock financial insights by subscribing to our monthly plan Subscribe Unlock nonprofit financial insights that will help you make more informed decisions Operations The people, governance practices, and partners that make the organization tick Officers, directors, trustees, and key employeesraymond mill structure and working principle The whole structure of Raymond mill is composed of a host machine, analysis, plumbing, air blower, finished cyclone separator, jaw crusher, bucket elevator, electromagnetic vibration feeder, electric motors and other componentsRaymond Mill,Raymond Mill Working PrincipleLoesche Mill: Principle of operation, design and functioning Principle of operation The grinding material is comminuted in the Loesche roller grinding mill between the rotating horizontal grinding track and the stationary grinding rollers Grinding is effected primarily by compression A certain amount of shear force increases the quantityLoesche Mills for industrial mineralsIn this rolling mill, there are two rolls used Two High Reversing Mill: In this type of mill, the rollers are both adjustable In these mills, rotation of that two rolls is made in two different directions In this operation, the metal is passed between two rollers that rotate at the same speed but it Rolling Process: Working, Application, Defects, Type of Jan 11, 2016 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill sizeBall Mill: Operating principles, components, Uses

Rolling (metalworking) Wikipedia

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property The concept is similar to the rolling of doughRolling is classified according to the temperature of the metal rolled If the temperature of the metal is above its Original Structure: built 1830s, Spring Mill Village Current Structure: moved to Spring Mill Story: In the 1800s, it was customary for men to wear hats when outside The demand for hats led to the presence of a hat shop on this location John Lindsey, a hatter from Bono, Indiana, built his shop around 1830 Most common were felted wool hatsstories and structures 2 INgovPressure relief valve will have two sections ie Body section and pilot valve section Body section of relief valve will have a piston which will be retained to its position or seat due to the action of spring force Pilot valve section will control the piston movement with the help of hydraulic forcePRESSURE RELIEF VALVE WORKING PRINCIPLE AND ITS INTERNAL The wheel train include gear 2, 3, 4 There are two functions for the wheel train Transfer the power from the Mainwheel to the Balance Wheel When the energy goes through the wheel train, the high torque form the Mainwheel will become the high speed oscillation at theBalance WheelMechanical Clock, Mechanical Watch Structure TheoryNov 14, 2020 The movement of plate C presses the spring E, Which ultimately presses the clutch plate D on the flywheel against the spring G This makes the clutch engaged The spring G keeps the clutch disengaged at low speeds at about 500rpm The stop H limits the movement of the weights due to the centrifugal SemiCentrifugal ClutchClutch: 9 Different Types of Clutches How They Works?

A BASIC UNDERSTANDING OF THE MECHANICS OF

on wear is another issue Stresses from Hertzian pressure in 4high cold mill back up rolls were measured years ago, the results were never published, but of high interest also, maybe later K H Schröder July 2003 K H Schröder: A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS File: SCHROEDERROLLSDOCIn this rolling mill, there are two rolls used Two High Reversing Mill: In this type of mill, the rollers are both adjustable In these mills, rotation of that two rolls is made in two different directions In this operation, the metal is passed between two rollers that rotate at the same speed but it Rolling Process: Working, Application, Defects, Type of Oct 09, 2007 Mill was raised in the tradition of Philosophical Radicalism, made famous by Jeremy Bentham (1748–1832), John Austin (1790–1859), and his father James Mill (1773–1836), which applied utilitarian principles in a selfconscious and systematic way to issues of institutional design and social reform Utilitarianism assesses actions and Mill’s Moral and Political Philosophy (Stanford Dec 23, 2018 A structure is represented by a numeric character on the specification of the grinding wheel The structure is directly proportional to the structure number if the structure number lies in between the 0 to 7 then it known as a dense structure whereas if it is in between 816 then it is known as an open structureGrinding Machining Process : Complete Notes mech4studySep 17, 2014 A mechanical seal consists of 2 principle components One component is stationary and the other rotates against it to achieve a seal (Figure 2) There are many types of mechanical seal, ranging from simple single spring designs to considerably more complex cartridge seal typesMechanical Seal Basics VibrAlign

Rolling (metalworking) Wikipedia

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property The concept is similar to the rolling of doughRolling is classified according to the temperature of the metal rolled If the temperature of the metal is above its Pressure relief valve will have two sections ie Body section and pilot valve section Body section of relief valve will have a piston which will be retained to its position or seat due to the action of spring force Pilot valve section will control the piston movement with the help of hydraulic forcePRESSURE RELIEF VALVE WORKING PRINCIPLE AND ITS Sep 17, 2017 Thermal Power Plant : Principle, Parts, Working, Advantages and Disadvantages It is a container which is upper side of mill and used to continuously provide coal for mill machine The minimum capacity of bunker is around 10 times of mill capacity Operation cost is high compare to hydro and nuclear power plantThermal Power Plant : Principle, Parts, Working Nov 14, 2020 The movement of plate C presses the spring E, Which ultimately presses the clutch plate D on the flywheel against the spring G This makes the clutch engaged The spring G keeps the clutch disengaged at low speeds at about 500rpm The stop H limits the movement of the weights due to the centrifugal SemiCentrifugal ClutchClutch: 9 Different Types of Clutches How They Works?The Working Principle, Types, And Applications of a Manometer A device used to measure the pressure at any point in a fluid, manometers are also used to measure the pressure of gas and air This ScienceStruck article explains the working principle of a manometer, and provides a review of different types of manometers and their applicationsThe Working Principle, Types, And Applications of a

Variable Frequency Drive Working Principle

Rectifier: the working principle of rectifier is changing the incoming alternating current (AC) supply to direct current (DC) Different designs are available and these are selected according to the performance required of the variable frequency driveOversize particles, not easily broken, drop through the mill and may be recycled or discarded Thus foreign materials, such as metal and stones, are discharged before they are forced through the screen causing damage Fig 1 Hammer Mill 22 Attrition Mills Attrition mills use the hammermill principle to a certain extent; ie, shattering by Chapter 18 Feed Milling Processes Home Food and Mar 28, 2020 According to John Stuart Mill, the four principles of taxation are that the system be efficient, understandable and equitable and those who benefit from publiclyprovided services should sponsor and pay for those services through taxes A good tax system follows the four principles of taxationWhat Are the Principles of Taxation? ReferenceInterestingly, the invention of the rolling mill in Europe may be attributed to Leonardo da Vinci in his drawings The earliest rolling mills in crude form but the same basic principles were found in Middle East and South Asia as early as 600 BCEWhat Is A Rolling Mill? Metal Processing Machinery The principle of mill operation is the impingement of the solids between pieces of media The majority of media motion and milling occurs on the surface of the bed of media where the media is cascading If there are too few solids, then media will strike media with little milling effect but with accelerated wear of the media and mill shell Variables in Ball Mill Operation Paul O Abbe®

A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING

on wear is another issue Stresses from Hertzian pressure in 4high cold mill back up rolls were measured years ago, the results were never published, but of high interest also, maybe later K H Schröder July 2003 K H Schröder: A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS File: SCHROEDERROLLSDOCOversize particles, not easily broken, drop through the mill and may be recycled or discarded Thus foreign materials, such as metal and stones, are discharged before they are forced through the screen causing damage Fig 1 Hammer Mill 22 Attrition Mills Attrition mills use the hammermill principle to a certain extent; ie, shattering by Chapter 18 Feed Milling Processes Home Food and Dec 23, 2018 A structure is represented by a numeric character on the specification of the grinding wheel The structure is directly proportional to the structure number if the structure number lies in between the 0 to 7 then it known as a dense structure whereas if it is in between 816 then it is known as an open structureGrinding Machining Process : Complete Notes mech4studyInterestingly, the invention of the rolling mill in Europe may be attributed to Leonardo da Vinci in his drawings The earliest rolling mills in crude form but the same basic principles were found in Middle East and South Asia as early as 600 BCEWhat Is A Rolling Mill? Metal Processing Machinery Oct 09, 2007 Mill was raised in the tradition of Philosophical Radicalism, made famous by Jeremy Bentham (1748–1832), John Austin (1790–1859), and his father James Mill (1773–1836), which applied utilitarian principles in a selfconscious and systematic way to issues of institutional design and social reform Utilitarianism assesses actions and Mill’s Moral and Political Philosophy (Stanford

PRESSURE RELIEF VALVE WORKING PRINCIPLE AND ITS INTERNAL

Pressure relief valve will have two sections ie Body section and pilot valve section Body section of relief valve will have a piston which will be retained to its position or seat due to the action of spring force Pilot valve section will control the piston movement with the help of hydraulic forceSep 17, 2017 Thermal Power Plant : Principle, Parts, Working, Advantages and Disadvantages It is a container which is upper side of mill and used to continuously provide coal for mill machine The minimum capacity of bunker is around 10 times of mill capacity Operation cost is high compare to hydro and nuclear power plantThermal Power Plant : Principle, Parts, Working Rectifier: the working principle of rectifier is changing the incoming alternating current (AC) supply to direct current (DC) Different designs are available and these are selected according to the performance required of the variable frequency driveVariable Frequency Drive Working PrincipleThe Working Principle, Types, And Applications of a Manometer A device used to measure the pressure at any point in a fluid, manometers are also used to measure the pressure of gas and air This ScienceStruck article explains the working principle of a manometer, and provides a review of different types of manometers and their applicationsThe Working Principle, Types, And Applications of a 8 PRINCIPLES OF OPERATION OF SYNCHRONOUS MACHINES Voltage (e) α α E (phasor) ω Fig 17 A phasor E, that can represent the voltage impressed on a circuitThe phasor is made of a vector with magnitude proportional to the magnitude of E, rotating at a constant rotational speed ωTHEORY, CONSTRUCTION, AND OPERATION

San Francisco Maritime National Park Association Home

San Francisco Maritime National Park Association HomeUpon expiry of some mill operation time the mill operating elements (grinding balls) get worn In this case they are just added into the drum together with source material The maximum filling level of impact elements is 50 mm below the inlet nozzle circumference Specifications Ball diameter is 30 to 60 mmBall mills: design and operating principle StrommashinaThe Principle of Fluidized Bed Dryer: If air is allowed to flow through a bed of solid powdered material in the upward direction with the velocity greater than the settling rate of the particles, the solid particles will be blown up and become suspended in the air streamPrinciple and Working of Fluidized Bed Dryer (FBD