Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

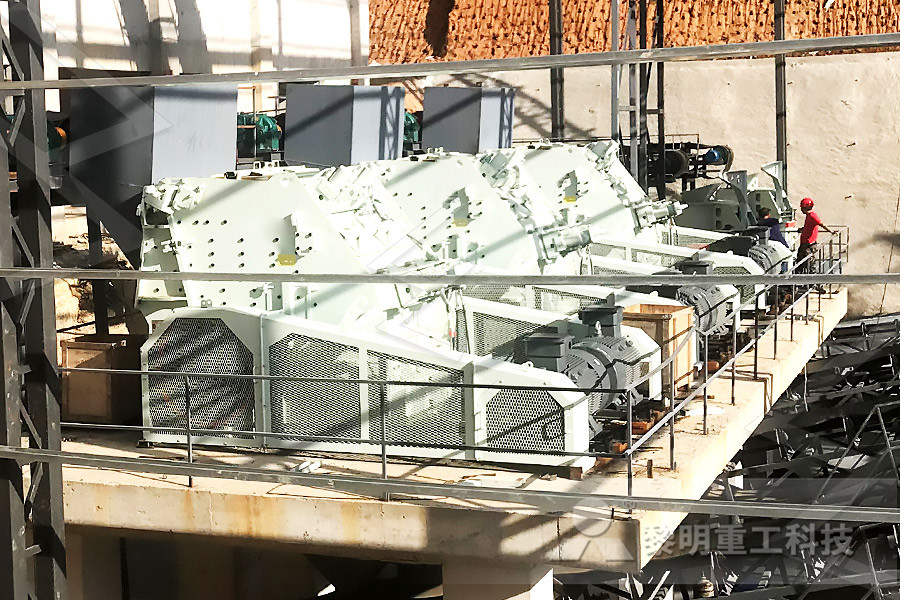

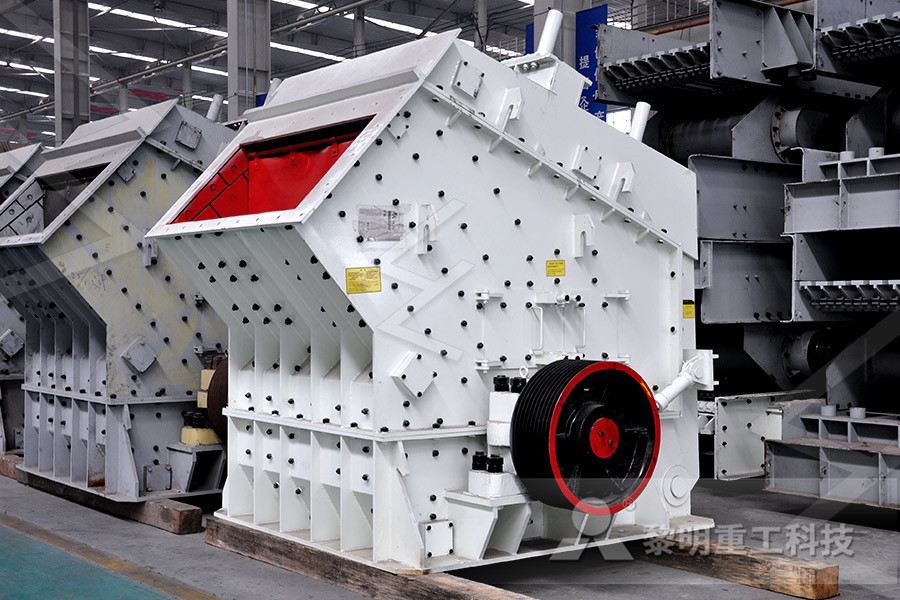

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

How to maximise slurry pumping efficiency in mining

Nov 10, 2020 Slurry pumps represent only 5 per cent of all centrifugal pumps installed in the industry Yet, this small segment, understandably, can represent 80 per cent of the operating costsSlurry pumps represent only 5% of all centrifugal pumps installed in the industry Yet, this small segment, understandably, can represent 80% of the operating costs However, if you look at how most mining facilities operate, too often the focus is only on optimizing grinding or extracting the oreHow to maximize slurry pumping efficiency in mining To pump slurries it’s very difficult task because the slurries are heavy Your considerations regarding the type of slurry, the choice of pump and to select a positive displacement slurry pump this type of challenges occurs when deciding the maintenance of centrifugal slurry pumps Important factors for considering a slurry pump for miningA Beginner’s Guide To Slurry Pumps For Mining Industries Many types of pumps are used for pumping slurries, but the most common slurry pump is the centrifugal pump (pictured above) The centrifugal slurry pump uses the centrifugal force generated by a rotating impeller to impact kinetic energy to the slurry, similar to how a waterlike liquid would move through a standard centrifugal pumpA Beginner's Guide To Pumping SlurryMar 17, 2020 How A Slurry Pump Work The Working Principle of a slurry pump is that: Under the action of centrifugal force, the slurry/mud is thrown from the center of the impeller to the outer edge and obtains energy to leave the outer edge of the impeller and enter the volute pump shell at high speed4 Popular Types of Slurry Pump How To Select A Right One

Mining Slurry Pump ,Professional Sand Pump Manufacturer

Ocean brand mining by adjusting the rotating speed of mining slurry pump, the pump flow and pump head can be improved effectivelySlurry pumps represent only about 5% of all centrifugal pumps installed in the mining industry, but slurry pumping is responsible for up to 80 % of the total operating pumping costs Due to high operating expenses, even small improvements in pumping efficiency reduce the total pumping costs significantlySlurry pumping Slurry pumps save time and money in mining and mineral excavation Work hard, around the clock Mining’s harsh environments are complex and hazardous Submersible pumps need to operate safely in potentially explosive environments, abrasive slurries, and chemically corrosive solutionsSubmersible pumps for the mining industry Industrial ’s trackrecord also includes the development of many modern mining technologies, so we know how to extend results beyond individual pump performance to ensure that your pumps work in synergy with your other equipment for optimal production and minimized downtimeServices for slurry pumping A slurry pump is a machine that conveys slurry or water to drill holes to washing during drilling Mine slurry pumps are the main part of mining types of equipment The engine drives the crankshaft of the pump to rotate And, the crankshaft drives the Piston or plunger by crosshead to do reciprocating motion which in the pump bowlSlurry Pump Manufacturers JXSC Mining

A Beginner’s Guide To Slurry Pumps For Mining Industries

To pump slurries it’s very difficult task because the slurries are heavy Your considerations regarding the type of slurry, the choice of pump and to select a positive displacement slurry pump this type of challenges occurs when deciding the maintenance of centrifugal slurry pumps Important factors for considering a slurry pump for miningMany types of pumps are used for pumping slurries, but the most common slurry pump is the centrifugal pump (pictured above) The centrifugal slurry pump uses the centrifugal force generated by a rotating impeller to impact kinetic energy to the slurry, similar to how a waterlike liquid would move through a standard centrifugal pumpA Beginner's Guide To Pumping Slurry5 Driving Device Elastic coupling drive, narrow Vbelt drive, gear drive and variable frequency drive How A Slurry Pump Work The Working Principle of a slurry pump is that: Under the action of centrifugal force, the slurry/mud is thrown from the center of the impeller to the outer edge and obtains energy to leave the outer edge of the impeller and enter the volute pump shell at high speed4 Popular Types of Slurry Pump How To Select A Right One Nov 08, 2018 Avoiding cavitation is easy if you have the right pump You need to know the required critical suction pressure – or net positive suction head (NPSH) – for your system and choose a slurry pump that operates clear of that pressure 2Determine PUMPS: Five slurry pump hacks you need to know Canadian Slurry pumps are mainly responsible for the transportation of mineral slurry in beneficiation processes And there are many types of pumps in the market As one of the slurry pump manufacturers, Xinhai has made some improvement on the slurry pump for saleSlurry Pump Miningpedia

Improving operational efficiencies in slurry pumping

Xylem Water Solutions Australia product and marketing manager for dewatering, Paul Gaby, says the company’s Flygt 5000 Series submersible slurry pumps address many of the common “pain points Slurry pumps save time and money in mining and mineral excavation Work hard, around the clock Mining’s harsh environments are complex and hazardous Submersible pumps need to operate safely in potentially explosive environments, abrasive slurries, and chemically corrosive solutionsSubmersible pumps for the mining industry Industrial Aug 20, 2015 How EDDY Pumps Work Vs Centrifugal pumps EDDY Pump technology explained Simulation video of the Eddy Pump slurry pumps compared to a traditional ceEDDY Pump Vs Centrifugal How Our Slurry Pump Work’s trackrecord also includes the development of many modern mining technologies, so we know how to extend results beyond individual pump performance to ensure that your pumps work in synergy with your other equipment for optimal production and minimized downtimeServices for slurry pumping Mine slurry pumps are the main part of mining types of equipment The engine drives the crankshaft of the pump to rotate And, the crankshaft drives the Piston or plunger by crosshead to do reciprocating motion which in the pump bowl Under alternating action of the suction valve and outlet valve, the pump accomplishes the purpose that the Slurry Pump Manufacturers JXSC Mining

Slurry Pumping Handbook AU

Slurry Pumping Handbook – AU Page 6 Issued: Feb 2000 The centrifugal slurry pump must be designed to allow the passage of abrasive particles which can at time be extremely large The largest Warman slurry pump, for example, can pump particles up to 530mm in spherical size Slurry pumps therefore need much wider and heavier impellers to Our slurry pumps are used for transporting corrosive/abrasive and high concentration slurry to the mining industries such as gold, silver, iron ore, diamond, platinum etc Slurry Pump is mainly used for heavywearing and heavyduty uses Slurry Pump moves the volume of slurry and used for the disposal of ash from fossil fuel power plantsPowerful Slurry Pump for Mining Applications – [Effective Outotec's Basic Slurry Pump Handbook provides guidance about the sizing and selection of slurry pumps for different pumping applications in mining It presents the basics and gives practical tips on how to minimize the costs for the hydraulic transportation of solids Outotec provide Slurry Pump Basic Handbook to • Mining • Mineral processing • Construction Chapter 5 gives a brief overview of some common industries and applications for slurry pumps 6 Slurry pump types Pumps that work fully submerged in slurry, cooled by the ambient liquid The slurry temperature may not exceed 40°C 2 Pumps that work at times with the motor partiallyGuidelines for slurry pumping Pumps! That's what it's about• Mining • Mineral processing • Construction Chapter 5 gives a brief overview of some common industries and applications for slurry pumps 6 Slurry pump types Pumps that work fully submerged in slurry, cooled by the ambient liquid The slurry temperature may not exceed 40°C 2 Pumps that work Guidelines for slurry pumping Pumps! That's what it's about

PUMPS: Five slurry pump hacks you need to know Canadian

Nov 08, 2018 Avoiding cavitation is easy if you have the right pump You need to know the required critical suction pressure – or net positive suction head (NPSH) – for your system and choose a slurry pump The mining slurry pump is an indispensable auxiliary equipment in mineral processing plantIt is mainly used for the hydraulic conveying of solid materials such as concentrate, tailings, ash and sediment Guide of Slurry Pumps MiningpediaHose pumps can circulate slurry SGs of 16 to 18 or up to 80% solid content The traditional centrifugal pump loses efficiency when the slurry SG reaches 13 or 30% solids With this limitation, slurry pumps Pumping Slurry In the Mining Industry Verder LiquidsSlurry pumps are mainly responsible for the transportation of mineral slurry in beneficiation processes And there are many types of pumps in the market As one of the slurry pump manufacturers, Xinhai has made some improvement on the slurry pump Slurry Pump MiningpediaSlurry Pumping Handbook – AU Page 6 Issued: Feb 2000 The centrifugal slurry pump must be designed to allow the passage of abrasive particles which can at time be extremely large The largest Warman slurry pump, for example, can pump particles up to 530mm in spherical size Slurry pumps Slurry Pumping Handbook AU

EDDY Pump Vs Centrifugal How Our Slurry Pump Work

Aug 20, 2015 How EDDY Pumps Work Vs Centrifugal pumps EDDY Pump technology explained Simulation video of the Eddy Pump slurry pumps Our slurry pumps are used for transporting corrosive/abrasive and high concentration slurry to the mining industries such as gold, silver, iron ore, diamond, platinum etc Slurry Pump is mainly used for heavywearing and heavyduty uses Slurry Pump moves the volume of slurry Powerful Slurry Pump for Mining Applications – [Effective ’s trackrecord also includes the development of many modern mining technologies, so we know how to extend results beyond individual pump performance to ensure that your pumps work in Services for slurry pumping Designed for handling strong abrasive and high concentration slurries, EHM series slurry pumps are cantilevered heavy duty slurry pumps with metal liner With thick wear parts and heavy duty support, EHM series could run in series in the allowable range of pump Mine pump,Mine pumps,Centrifugal slurry pumpIf the slurry contains solids of about 5%, the centrifuge pump as a mine dewatering purposes for irrigation should be used, the general pumps for transferring slurry containing solids between 5% and 20% are used, heavy slurry with about 40% solids with heavy transfer pumps And if the amount of solids in the slurry Slurry pump Zimaksan Co

How To Reduce The Wear Of Slurry Pump? Industry News

Dec 10, 2020 34 It is strictly forbidden to work when the slurry in the pool is evacuated, because the slurry pump will not only vibrate violently but also affect the service life of the pump 35 Each pump GIW engineers at the Hydraulic Lab test a wide variety of slurry types at different flow rates and duty points GIW offers a range of slurry pumps designed for flow rates between 100 and 100,000 gpm and beyond, so customers are covered no matter what or how much they are pumping Let GIW help find the best pump PUMPS: Why do slurry pumps wear quickly at low flow rates Mining Slurry Pump, , , , Mining Slurry Pump, BQ series electric pump BQS(BQW) Mining Pump BQG Diaphragm Pump Mud Pump Factory Selling Ground Anchor Drilling Machine Factory Mining Slurry Pump longtopmining