Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

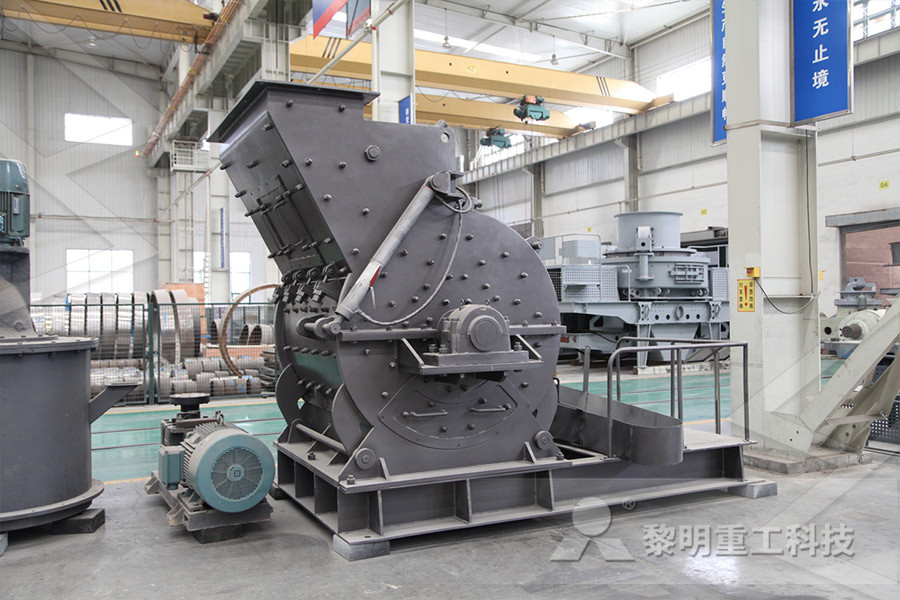

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Impact Crusher VS Jaw Crusher:What Are the Differences?

Jaw crusher and impact crusher are different in structure, principle, characteristics and application In actual production, the most suitable crushing equipment should be selected according to factors such as the hardness of the material, particle size, crushing stage, etcJaw Crusher Vs Impact Crusher Gravel Mill Although jaw crushers and impact crushers have various models and a wide range of production capacity in general the former has a larger production capacity than the latter Different output fineness It can be seen from the use of jaw crusher is a first level crushing equipment for materials and the impact crusher is a second crusher or aEquipment Productivity Of Jaw And Impact CrushersThe high performance range of jaw and impact crushers combine productivity with outstanding durability to achieve the most efficient levels of product reduction across primary, secondary and tertiary crushing applications Tracked Jaw and Impact Crushers Power Equipment Jaw Crusher And Impact Crusher Jaw Crusher and Impact Crusher are common crushing equipment in the crushing market, but a lot of people especially the people who have just get into this industry still have many questions, they don ’ t understand what is different between them Today, let ’ s talk about the difference between these two machines in practical applicationThe Difference Between Jaw Impact CrusherCompared with traditional jaw crusher, PEW series european type jaw crushers pays more attention on details in the process of design and manufacture It uses highstrength materials, advanced manufacturing technology, which contributes to the stronger structure, higher reliability, larger crushing ratio, higher productivity, lower costPEW Series European Type Jaw Crusher

jaw crusher productivity pdf

Jaw crusher and impact crusher productivity pdf productivity of jaw and impact crushers pdf a crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock earliest crushers were hand held stones, where the weight of the stone provided a boost to muscle power, used against aCone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical product similar to impact crushers Cone crushers have traditionally been used as secondary and sometimes tertiary crushing stationsHow Does a Jaw Crusher Work Jaw Crusher Kemper EquipmentMay 13, 2019 Additionally, jaw crusher feed should be prescreened using a grizzly screen prior to crushing to remove material finer than the closedside setting Setting jaw crushers Ideally, the reduction ratio of a jaw crusher should be 6to1 There are different ways to calculate reduction ratio, but the best way is something called the P80 factorTips to maximize crushing efficiency Pit Quarry : Pit Apr 22, 2020 Impact Crushers – VSIs and HSIs Impactstyle crushers include VSIs, as well as horizontal shaft impactors (HSIs), and are best used with less abrasive rock types, like limestone These types of machines break apart material by the impacting forces of certain wear parts known as blow bars and impact plates or toggles Some operations also use impactstyle crushers after they have Types of Rock Crushers Quarry Crushing Equipment KemperJaw Crusher And Impact Crusher Jaw Crusher and Impact Crusher are common crushing equipment in the crushing market, but a lot of people especially the people who have just get into this industry still have many questions, they don ’ t understand what is different between them Today, let ’ s talk about the difference between these two machines in practical applicationThe Difference Between Jaw Impact Crusher

Tracked Jaw and Impact Crushers Power Equipment

offers robust and reliable mobile tracked jaw and impact crushers for the materials processing industry The high performance range of jaw and impact crushers combine productivity with outstanding durability to achieve the most efficient levels of product reduction across primary, secondary and tertiary crushing applicationsImpact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor power So for these impact crusher parameter selection and calculation method of everybody understand? Following up and have a lookImpact Crushers Design And CalculationsMay 13, 2019 Additionally, jaw crusher feed should be prescreened using a grizzly screen prior to crushing to remove material finer than the closedside setting Setting jaw crushers Ideally, the reduction ratio of a jaw crusher should be 6to1 There are different ways to calculate reduction ratio, but the best way is something called the P80 factorTips to maximize crushing efficiency Pit Quarry : Pit Jaw crusher and impact crusher productivity pdf productivity of jaw and impact crushers pdf a crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock earliest crushers were hand held stones, where the weight of the stone provided a boost to muscle power, used against ajaw crusher productivity pdfLokotrack® crushers are more customizable and the range is wider, covering mobile cone, impact and jaw crushers Nordtrack™, on the other hand, is ideal if you work in shortterm contracting jobs or are just starting your own operations The family consists of two mobile jaw crusher models and one mobile impact crusherMobile crushers

Jaw Crusher VS Cone Crusher Advantages and Disadvantages

Also is the most mainstream crusher type Jaw crusher is usually used as a primary crusher and secondclass crusher Cone crusher is usually used as secondary crusher or threestage crusher machine Jaw crusher and cone crusher are usually arranged on the stone crusher plant in two stages Jaw crusher breaks the rock to 10 ~ 30 cm sizeOur range of jaw, impact, and cone crushers boast excellent productivity and reliability all of which is supported by Foreman Equipment Ltd Foreman Equipment Ltd is an established ® dealer selling and servicing with a broad customer base throughout The Lower mainland, Vancouver Island, The Okanagan, Kootenays, The Peace Country Crushing Equipment Sales Rental in BC AlbertaFor production of building aggregates, can offer such core crushing machines like jaw crusher, impact crusher, cone crusher and sandmaking machine So far, we have developed 10 series which include over 100 machine models that can be matched freely so as to meet various demands on yielding and types of building aggregatescone crusher and VSI series for secondary or tertiary operating characterstics of jaw and impact crushers pdf Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipmentoperating characterstics of jaw and impact crushers pdfThe project uses granite as the main raw material, and the main equipment is equipped with Leimeng Machinery PE900 * 1200 jaw crusher, multiple S240 cone crushers, multiple 3YKJ2470 vibrating screens, etc, producing about 450 tons of multispecific fine sand per hour Aggregate for local road and bridge construction projectsChina Crushing equipment, Grinding equipment, impact

How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment

Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical product similar to impact crushers Cone crushers have traditionally been used as secondary and sometimes tertiary crushing stationsSpecial equipment for crushing production line (sand stone production line) is a special equipment for the production of sand and stone for construction Stone equipment, including jaw crusher, stone crusher, impact crusher, impact crusher, vibratMining Industry: How does a stone crushing plant work? QuoraCrushing Equipment For production of building aggregates, can offer such core crushing machines like jaw crusher, impact crusher, cone crusher and sandmaking machine So far, we have developed 10 series which include over 100 machine models that can be matched freely so as to meet various demands on yielding and types of building aggregatesEquipments Industrial Technology GroupJaw Crusher And Impact Crusher Jaw Crusher and Impact Crusher are common crushing equipment in the crushing market, but a lot of people especially the people who have just get into The Difference Between Jaw Impact CrusherImpact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor power So for these impact crusher Impact Crushers Design And Calculations

Five factors affecting new jaw crusher productivity

Five factors affecting new jaw crusher productivity Time: Factors new jaw crusher productivity, including many in the course of daily operations, due to the operator neglect of these factors led to a significant reduction in the production efficiency of the crusherJaw Crushers Safe Versatile Productivity Telsmith manufactures a wide range of crushing equipment that’s engineered with the highest standards of safety, productivity, and ease of maintenance for mining, aggregates, crushed stone productionJaw Crushers TelsmithChoosing The Right Crusher A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing Crushers Types of Crushing Equipment Jaw, Cone Impact Tricon According to the different needs of customers, provide a diverse portfolio of mobile crushing equipment, to meet the customer's production needs There is portable mobile jaw crusher plant, impact crusher plant, cone crusher plant Mobile jaw crusher plant: vibrating feeder, jaw crusherMobile Crusher Mobile Jaw Impact Cone Crushers Also is the most mainstream crusher type Jaw crusher is usually used as a primary crusher and secondclass crusher Cone crusher is usually used as secondary crusher or threestage crusher machine Jaw crusher and cone crusher are usually arranged on the stone crusher plant in two stages Jaw crusher Jaw Crusher VS Cone Crusher Advantages and Disadvantages

Crushing Equipment Sales Rental in BC Alberta

Our range of jaw, impact, and cone crushers boast excellent productivity and reliability all of which is supported by Foreman Equipment Ltd Foreman Equipment Ltd is an established ® operating characterstics of jaw and impact crushers pdf Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipmentoperating characterstics of jaw and impact crushers pdfEagle Crusher has earned its worldclass reputation for innovative research, excellence in manufacturing, and quality products due to its philosophy of putting customers needs first Our #1 goal World Class Manufacturer of Portable Rock Crushing EquipmentPrimary crushing with impact crushers The primary impact crusher offers high capacity and is designed to accept large feed sizes The primary impact crushers are used to process from 200 t/h Crushers All crusher types for your reduction needs The production capacity of jaw crusher directly affects the economic profits of investors And the production capacity of jaw crusher is affected by many factors, such as the properties of raw material (hardness, size, and bulk density), type size of jaw crusher, operation condition of jaw crusher Solutions To Improve The Production Capacity Of Jaw Crusher

Crusher, stone crusher, aggregate processing equipment

Production capacity is the quantitative index to measure the processing ability of jaw crusher The production capacity of jaw crusher directly affects the economic profits of investors And the production capacity of jaw crusher is affected by many facto also called vertical shaft impact crusher, is a very important sand making equipment Crushing Equipment For production of building aggregates, can offer such core crushing machines like jaw crusher, impact crusher, cone crusher and sandmaking machine So far, we Equipments Industrial Technology Group