Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

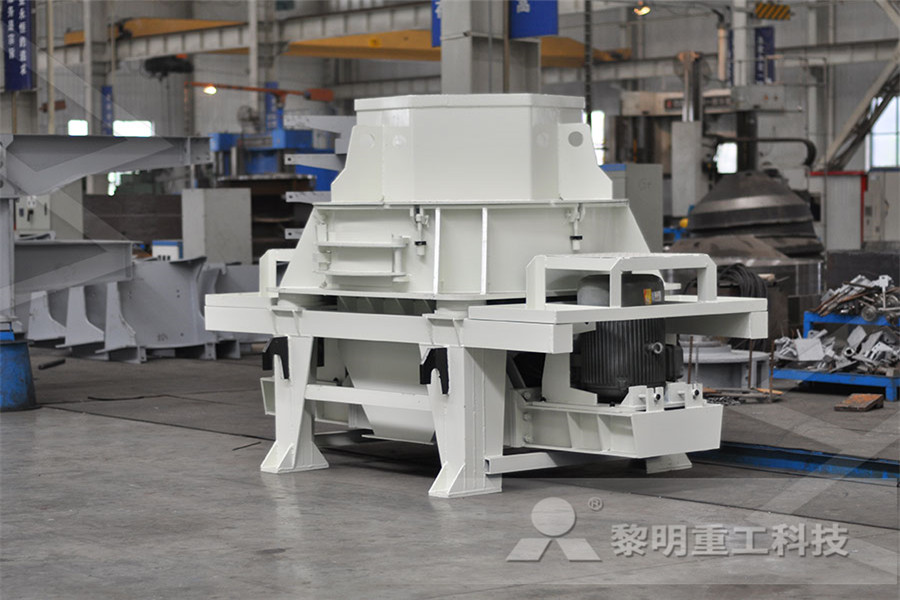

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Minerals Processing Systems JW SERIES JAW CRUSHERS

machines, based on dry, free flowing material with a crushing work index of 16 and a bulk density of 100 lbs/cu ft (1600 kg/cu m) The table requires careful interpretation for particular materials and applications as machine capacity can be greatly affected by material properties and method of feeding JW Series Jaw Crusher CapacitiesMay 02, 2015 There have been reported cases of the crusher jaw failure due to the high level of impact, tear and shear stresses experienced by the crusher jaw during service The purpose of this paper is to select a suitable candidate material for the design of crusher jaw that can sustain fracture by any of the three modes of failure – tear, shear and impact at low cost using CES EduPackMaterial Selection for Crusher Jaw in a Jaw Crusher EquipmentNov 09, 2015 18 Adelana Rasaki Adetunji et al: Material Selection for Crusher Jaw in a Jaw Crusher Equipment adopted for various designs (Chan and Zhou, 199 4 and Dieter, 1991) (PDF) Material Selection for Crusher Jaw in a Jaw Crusher Jaw crushers are most commonly defined by gape size, open and closed side sets, and capacity There are a wide range of jaw crusher sizes for varying production and product size requirements The plates of a jaw crusher are used to apply compressive forces that induce tensile stresses within particles, causing fractureJAW CRUSHER SELECTION AND PERFORMANCE PRIDICTING Jaw Crusher Product Gradations Footnote: These product curves are to be used as a guide only Crusher product is dependant on feed material properties Please consult Jaques for advice on product gradations for specific feed materials Single Toggle Jaw Crusherdd 7 22/2/11 11:52:32 AMSingle Toggle Jaw Crusher TEREX JAQUES SINGLE TOGGLE

jaw crusher requirements on material properties

ASTM G81 Standard Test Method for Jaw Crusher Gouging ,Materials homogeneous in structure and properties are the most appropriate test materials; however, surface treated and composite materials can also be tested The test involves a small laboratory jaw crusher that crushes presized hard rock materials, such as a hard morainal gravel, or some other crushable substanceConcrete aggregates May 10, 2017 Jaw crusher is the first appeared in the crusher, but also the strongest crushing capacity, the highest frequency of a basic crushing equipment material 3, jaw crusher What are the causes of jaw crusher blocking material? by Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square“Computer Aided Design of Jaw crusher”A jaw crusher robustly constructed singletoggle type with one fixed jaw plate and one moving jaw plate Designed for the smaller laboratory, or use by prospectors It is capable of quickly crushing materials up to 85% of the jaw opening (125 mm x 100 mm)Laboratory Jaw Crusher 911MetallurgistMetallurgical ContentJaw Crusher Designs Style for SaleJaw Crusher TerminologyJAW CRUSHERSDoubleToggle Jaw CrushersSingletoggle Jaw CrushersSizing Jaw CrushersForced Feed Jaw CrushersBulldog Jaw CrusherTraylor Jaw CrusherJaw Crusher Foolproof A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and Jaw Crusher Working Principle

JAW CRUSHER SELECTION AND PERFORMANCE PRIDICTING

Jaw crushers are most commonly defined by gape size, open and closed side sets, and capacity There are a wide range of jaw crusher sizes for varying production and product size requirements The plates of a jaw crusher are used to apply compressive forces that induce tensile stresses within particles, causing fractureJaw Crusher Product Gradations Footnote: These product curves are to be used as a guide only Crusher product is dependant on feed material properties Please consult Jaques for advice on product gradations for specific feed materials Single Toggle Jaw Crusherdd 7 22/2/11 11:52:32 AMSingle Toggle Jaw Crusher TEREX JAQUES SINGLE TOGGLE What material can jaw crusher crush The jaw crusher crushing capacity is relatively large, and feed inlet is large, so widely used to crush hardness, large stone or mineral Such as pebbles, granite, marble, basalt, limestone, gold, silver, lead, zinc, hematite, manganese, copper and so on11 Jaw Crusher FAQ Price, Application, Spare PartsSolution: Understand various parameters of the PE series jaw crusher, especially the requirements for the material properties According to these requirements (such as size, hardness, etc), put in suitable materials Material jam is a common problem in the production process of mining equipmentFour Reasons Why A PE Series Jaw Crusher Is Jammed and How Feed Material Properties JAW CRUSHER WEAR PARTS IMPACT CRUSHER WEAR PARTS Jaw Die Selection Features V2 Jaws V2 Cheek Plates V1 Jaws Cheek Plates CSS Feed Opening C2, C3 C4 Mantle Bowl Liners CSS Feed Opening C38 C44 Mantle McCloskey Crusher Wear Parts Selection Guide

Solutions To Improve The Production Capacity Of Jaw Crusher

And the production capacity of jaw crusher is affected by many factors, such as the properties of raw material (hardness, size, and bulk density), type size of jaw crusher, operation condition of jaw crusher and so on And the low production capacity is mainly caused by the low discharging capacity In this article, we mainly introduce some In this project, the material used for the outer shell of hairdryer should be investigated in terms of material selection to improve the material properties of the housing of the hairdryer and obtaining much more light and cost effective design Therefore, you are to select suitable material to meet these functional requirementsMaterials Selection ProjectThere are many different types of crusher, such as jaw, gyratory, cone (or disc) and impact crushers (Fig 159), each of which has various advantages and disadvantages according to the properties of the material being crushed and the required shape of the aggregate particles producedGyratory Crusher an overview ScienceDirect TopicsProperties The MF 14 S is a reliable mobile secondary crushing plant that it is used in the natural stone industry Specially designed for the requirements of second or third crushing stages in natural stone, it impresses with a high level of efficiency and availability The dieselelectric drive concept also reaches its full potential hereMF 14 S Mobile impact crushers Gyratory Crusher an overview ScienceDirect Topics A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which ha Jump to content Welcome to HIP Heavy Industry Machinery Co, Ltd Looking forward to your joining!gyratory crusher gear properties

Correct use method of jaw crusherNewsZhongxin Heavy Industry

Correct use method of jaw crusher Time: 14:49:32 The jaw crusher is a rough crushing equipment for the stone production line The function of the jaw crusher determines the equipment of the subsequent process When the jaw crusher works efficiently, it can meet the feeding requirements of the subsequent equipment and make it work at full capacityThe material does not meet the requirements of the jaw Construction Waste Crusher production process After entering the crushing chamber, the crushing effect can not be achieved, and the production efficiency is reduced, resulting in the phenomenon of material inclusionKeep the Construction Waste Crusher Away From The CardImpact stone crusher involves the use of impact rather than pressure to crush materials The material is held within a cage, with openings of the desired size at the bottom, end or at sides to (PDF) Design of Impact stone crusher machineSolution: Understand various parameters of the PE series jaw crusher, especially the requirements for the material properties According to these requirements (such as size, hardness, etc), put in suitable materials Material jam is a common problem in the production process of mining equipmentFour Reasons Why A PE Series Jaw Crusher Is Jammed and How And the production capacity of jaw crusher is affected by many factors, such as the properties of raw material (hardness, size, and bulk density), type size of jaw crusher, operation condition of jaw crusher and so on And the low production capacity is mainly caused by the low discharging capacity In this article, we mainly introduce some Solutions To Improve The Production Capacity Of Jaw Crusher

McCloskey Crusher Wear Parts Selection Guide (External) 001

Feed Material Properties JAW CRUSHER WEAR PARTS IMPACT CRUSHER WEAR PARTS Jaw Die Selection Features V2 Jaws V2 Cheek Plates V1 Jaws Cheek Plates CSS Feed Opening C2, C3 C4 Mantle Bowl Liners CSS Feed Opening C38 C44 Mantle Correct use method of jaw crusher Time: 14:49:32 The jaw crusher is a rough crushing equipment for the stone production line The function of the jaw crusher determines the equipment of the subsequent process When the jaw crusher works efficiently, it can meet the feeding requirements of the subsequent equipment and make it work at full capacityCorrect use method of jaw crusherNewsZhongxin Heavy IndustryThe material does not meet the requirements of the jaw Construction Waste Crusher production process After entering the crushing chamber, the crushing effect can not be achieved, and the production efficiency is reduced, resulting in the phenomenon of material inclusionKeep the Construction Waste Crusher Away From The CardIn this project, the material used for the outer shell of hairdryer should be investigated in terms of material selection to improve the material properties of the housing of the hairdryer and obtaining much more light and cost effective design Therefore, you are to select suitable material to meet these functional requirementsMaterials Selection ProjectProperties The MF 14 S is a reliable mobile secondary crushing plant that it is used in the natural stone industry Specially designed for the requirements of second or third crushing stages in natural stone, it impresses with a high level of efficiency and availability The dieselelectric drive concept also reaches its full potential hereMF 14 S Mobile impact crushers

(PDF) Design of Impact stone crusher machine

Impact stone crusher involves the use of impact rather than pressure to crush materials The material is held within a cage, with openings of the desired size at the bottom, end or at sides to Primary crushing plants can be equipped with gyratory crushers, jaw crushers, twinshaft sizers, doubleroll crushers, impact crushers or hammer crushers, depending on material properties and required throughputs We are able to provide mobile, semimobile or stationary plants and work together with our clients to choose the most suitable Primary Crushing Plants TAKRAF GmbHLaboratory Jaw Crusher Pulverisette 1 $ 100 This Laboratory Jaw Crusher is designed for fast and effective precrushing of very hard, hard, mediumhard, and brittle materials, even ferrous alloysLaboratory Crushers, Pulverizers, Grinders Laval LabProperties Primary crusher designed specially for the requirements in quarries thanks to its design, drive concept, and capacity The SStR 1250 x 1000 jaw crusher weighs as much as 49 tons, is equipped with an especially long crushing jaw, and has a drive power of 200 kWMC 125 Z Mobile jaw crushers Product Collection ' ' PRODUCT FOCUS Jaw Crushers CTHT Series CTHT Series Product Range CTHT Series Typical Physical Properties Design Feature • Heavyduty frame • Long crushing chamber • Hydraulic toggle relief system • Hydraulic adjustment • Heavy duty manganese or alloy jaw dies • Bolted construction Greater durability Increased capacity Protects against mechanical Trio® Product Guide Online Viewing Weir Minerals PDF

How To Choose The Right Crusher Parts? Qiming Machinery

As with the jaw crusher, material travels downward between the two surfaces being progressively crushed until it is small enough to fall out through the gap between the two surfaces Based on its frequency replacement and function, the gyratory crusher parts are divided into gyratory crusher spare parts and gyratory crusher wear parts No matter how tough the rock is, jaw crusher can subdue it! 17/11/2018 Fote Machinery manufactures various series and models of jaw crushers for different materials, no matter how tough the rock or stone is, FTM jaw crusher can subdue it The Detailed Description Henan Fote Machinery Co, Ltd Mobile crusher,Crusher