Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

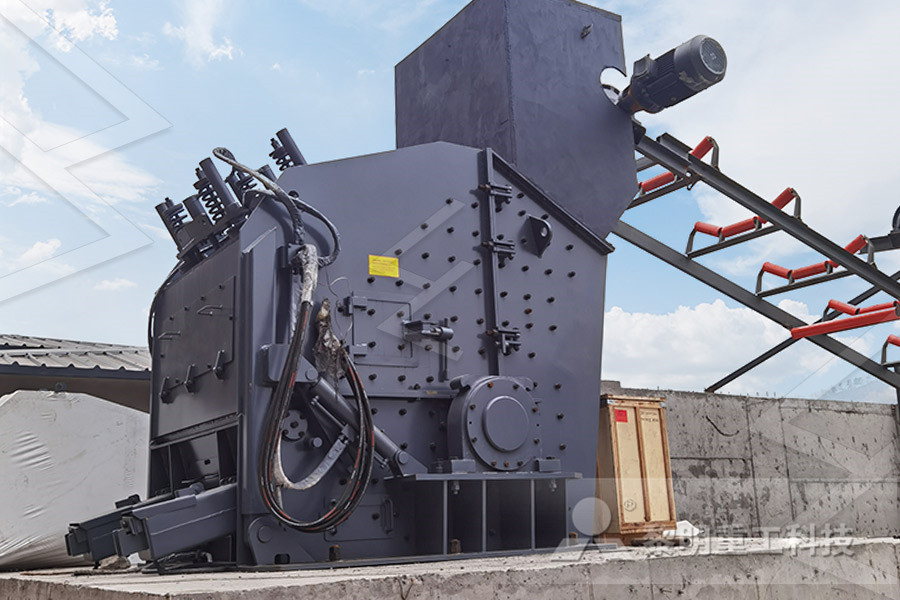

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Boiler Working Animation Steam Boilers, Waste Heat Boilers

Feb 24, 2013 Explains with working animations steam boilers, waste heat boilers and thermal liquid heaters Learn about boiler designs, advantages and disadvantages etc mill system in boiler animation Second Hand Concrete Batching Plants For Sale In Malaysia Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligen Raw Complex Gold Ore Processing Machinemill system in boiler animationmill system in boiler animation labruschetteriade A feed system, is nothing but a cyclic process that takes place between the turbine and the boiler3 killed in boiler explosion caught on camera Video ABC NewsApr 04, 2017 In St Louis that industrial boiler exploded with deadly consequences but a reminder more than 10 million homes across America have boilers and more than 100 million havemill system in boiler animation dlgcateringdeMilling System operation 9/4/2013 Steag OM Company 13 • Coal Firing •Ensure that the clean air flow test of the mill is completed satisfactorily •Boiler shall be lighted up with oil firing as per the regular operating procedure given in O M manual •Charge HP/LP bypass system following the Introduction to Boiler OperationThe Mills SteamHeating System HeatingHelp Posts: 343 July 2017 edited July 2017 in THE MAIN WALL The Mills SteamHeating System Read the full story here 0 Comments StephenPelosa Member Posts: 13 July 2017 I wish I could have seen a picture of that Amazing! 0 DanHolohan Member, Moderator, Administrator Posts: 15,037The Mills SteamHeating System — Heating Help: The Wall

Industrial boiler technology for beginners

How an industrial boiler system works The heart of an industrial boiler system is a hot water or steam boiler operated with a certain kind of fuel The boiler heats up or evaporates the water inside it, which is then transported to the consumers via pipe systems In Drying paper mill Process heating Sterilisation Humidification Power generation Steam Purity and Steam Quality Steam Purity Steam purity is an expression of the quantity of non water components in the steam Heat recovery systems Boiler Operating Costs Effective Internal Boiler WaterBoiler – Fundamentals and Best Practices2 BOILERS Bureau of Energy Efficiency 27 Syllabus Boilers: Types, Combustion in boilers, Performances evaluation, Analysis of losses, Feed water treatment, Blow down, Energy conservation opportunities 21 Introduction A boiler is an enclosed vessel that provides a means for combustion heat to be transferred into water until it becomes heated water or steam2 BOILERS Bureau of Energy EfficiencyA Burner Management System or BMS is a safety system used to assure safe startup, operation and shut down of process burners The BMS can be used in industries like Oil and Gas, Power Generation, Chemical or any other process that uses an industrial burner, furnaces, boilers or What is Burner Management System (BMS mill system in boiler animation labruschetteriade A feed system, is nothing but a cyclic process that takes place between the turbine and the boiler3 killed in boiler explosion caught on camera Video ABC NewsApr 04, 2017 In St Louis that industrial boiler exploded with deadly consequences but a reminder more than 10 million homes across America have boilers and more than 100 million havemill system in boiler animation dlgcateringde

Coal mill pulverizer in thermal power plants

Nov 17, 2012 2Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill The pulverized coal and air mixture is then transport to the boiler burner heating Water Makeup Storage Blowdown/Makeup Heat Exchanger Condensate Storage Mill Condensate(s) Treated Makeup S S S S S S S S S S S Usually Operated As A Grab Sample Point Condensate Filter/Polisher System CCNa CCNa pH SC pH SC Na DO SiO 2 Na CC SC SC SC NaSiO 2 (For Each) Desup Water Sweetwater Condenser FW Out FW In TU Boiler Questions52 Recovery Boiler Water TreatmentThe ball charge may occupy one third to half of the total internal volume of the shell The significant feature incorporated in the BBD mills is its double end operation, each end catering to one elevation of a boiler The system facilitated entry of raw coal and exit of pulverized fuel from same end simultaneouslyPulverizer WikipediaThe geothermal energy was used in a reboiler system to produce clean steam for the papermaking process By the 1970s, three papermaking machines were being supplied with clean steam from the Kawerau resource together with an 8MWe backpressure turbine generator used to supply some inhouse electricity for the millReboiler System an overview ScienceDirect TopicsSep 26, 2016 For industrial companies using a boiler for its facility, some type of boiler feed water treatment system is usually necessary to ensure an efficient process and quality steam generation The most appropriate boiler feed water treatment system will help the facility avoid costly plant downtime, expensive maintenance fees, and boiler failure as a result of scaling, corrosion, and fouling of the What Is a Boiler Feed Water Treatment System and How Does

Steam Boiler Working principle and Types of Boiler

Oct 23, 2020 Boiler or more specifically steam boiler is an essential part of thermal power plant Definition of Boiler Steam boiler or simply a boiler is basically a closed vessel into which water is heated until the water is converted into steam at required pressure This is most basic definition of boiler Working Principle of Boiler2 BOILERS Bureau of Energy Efficiency 27 Syllabus Boilers: Types, Combustion in boilers, Performances evaluation, Analysis of losses, Feed water treatment, Blow down, Energy conservation opportunities 21 Introduction A boiler is an enclosed vessel that provides a means for combustion heat to be transferred into water until it becomes heated water or steam2 BOILERS Bureau of Energy EfficiencyBoilers and radiators are not often installed in new homes, but many older residences still feature this type of heating system Furthermore, because this type of heating works well in multiresidence situations and larger buildings, steam heating and hotwater heating are still common in many apartment buildings, multifamily dwellings, and older business buildingsUnderstanding Steam Boiler Heating Systems HomeAdvisorA Burner Management System or BMS is a safety system used to assure safe startup, operation and shut down of process burners The BMS can be used in industries like Oil and Gas, Power Generation, Chemical or any other process that uses an industrial burner, furnaces, boilers or What is Burner Management System (BMS The Boiler is an important component of the system of steam power generation (power plant) Unit 7 PT IPMOMI PaitonProbolinggo Boilers can be divided into three systems of feed water system, steam system and fuel system The third integrated system so that if small changes will affect the quality of the resulting vapours temperature and pressureHazard and Operability study in Boiler System of The Steam

Steam Boiler Definition, Working Principle, Types, and

Generally, a steam boiler is a type of closed container, designed with steel for heating the water to generate steam by some energy source like burning of fuel with eventually The vapor generated may be delivered at lowpressure for the industrial progression work in sugar industries, cotton mills, and for generating steaming water that can be utilized for heat up fixing at much lowforceWithin a rotatingtype classifier, fine particles are passed through while coarse particles are eliminated by utilizing the relative balance of centrifugal force and centripetal force produced by a blade rotating at several dozen rpm and the flow of air MHI group offers a full lineup of pulverizer / mill systems from small to high capacity Heavy Industries, Ltd Global Website Boilers Burner Combustion Systems is a unique sales and service company for commercial and industrial boilers, burners and all other boiler room equipment We offer sales, service, and boiler rental for ondemand modular steam systems and cutting edge burners and burner management systems Burner Combustion Systems: Steam Boilers, Service RepairNov 17, 2012 2Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill The pulverized coal and air mixture is then transport to the boiler burner Coal mill pulverizer in thermal power plantsheating Water Makeup Storage Blowdown/Makeup Heat Exchanger Condensate Storage Mill Condensate(s) Treated Makeup S S S S S S S S S S S Usually Operated As A Grab Sample Point Condensate Filter/Polisher System CCNa CCNa pH SC pH SC Na DO SiO 2 Na CC SC SC SC NaSiO 2 (For Each) Desup Water Sweetwater Condenser FW Out FW In TU Boiler Questions52 Recovery Boiler Water Treatment

Coal Mill an overview ScienceDirect Topics

This 240 MW e coalfired boiler was converted to run on 100% wood pellets in 2011 After the conversion, the capacity is 180 MW e The boiler includes 24 biomass burners and four hammer mills Similar conversions of PC boilers to 100% biomass have been carried out at Drax power plant in the United KingdomWithin a rotatingtype classifier, fine particles are passed through while coarse particles are eliminated by utilizing the relative balance of centrifugal force and centripetal force produced by a blade rotating at several dozen rpm and the flow of air MHI group offers a full lineup of pulverizer / mill systems from small to high capacity Heavy Industries, Ltd Global Website Boilers In case of a feed system in an auxiliary boiler, as found on diesel propulsion ships, the drain tank or the hot well is open to the atmosphere While in a high pressurized system, no part of the system is open to the atmosphere A feed system, is nothing but a cyclic process that takes place between the turbine and the boilerBoiler Feed Water System Diagram and Explanation What is The geothermal energy was used in a reboiler system to produce clean steam for the papermaking process By the 1970s, three papermaking machines were being supplied with clean steam from the Kawerau resource together with an 8MWe backpressure turbine generator used to supply some inhouse electricity for the millReboiler System an overview ScienceDirect TopicsHistory • Soda pulping process patented, 1854 • Soda recovery via incineration patented, 1865 • First successful soda mill, 1866 • Kraft pulping process patented by Dahl, 1884 • First commercially viable kraft mill, Sweden, 1885 • Kraft recovery furnace, 1930’sKraft Pulping and Recovery Process basics

Hazard and Operability study in Boiler System of The Steam

The Boiler is an important component of the system of steam power generation (power plant) Unit 7 PT IPMOMI PaitonProbolinggo Boilers can be divided into three systems of feed water system, steam system and fuel system The third integrated system so that if small changes will affect the quality of the resulting vapours temperature and pressureA Burner Management System or BMS is a safety system used to assure safe startup, operation and shut down of process burners The BMS can be used in industries like Oil and Gas, Power Generation, Chemical or any other process that uses an industrial burner, furnaces, boilers or What is Burner Management System (BMS Feb 01, 2015 The reversereturn piping system is more costly, due to the additional length of return piping required, but is often justified where flow control is critical For hydronic systems that provide both heating and cooling, the distribution system may be configured as either a 2pipe system or a 4pipe system A 2pipe system is shown in Figure 3Understanding Thermal Systems: Hydronic Heating and Boiler efficiency is mainly depended on the amount of losses in the system In high capacity pulverized coal fired boilers the total losses account to about 12 to 14% Roughly 50% of the losses are governed by fuel properties like hydrogen in fuel, moisture in fuel and ambient air conditions The other 50% losses are carbon loss and dry gas lossHow to Run a Coal Fired Boiler at the Best Efficiency Water Tube Boilers: Used for high steam demand and high pressure requirements Capacity range of 4,500– 120,000 kg/hour Combustion efficiency of water tube boiler is enhanced by induced draft air provisions These boilers need good quality water and needs water treatment plant for maintaining the required water quality for boilersSteam Boiler Types, Construction and Working Principle

How Does a Boiler Work? A New York Tech Explains – Ranshaw

While traditional boilers are designed to only provide central heating, some boilers are designed to also function as a hot water heater Boilers that are designed to provide heating and hot water are either: Tankless coil systems Indirect systems Tankless coil systems use the boiler’s heat exchanger to heat water on demand That means, any Feb 21, 2020 Their most popular boiler is the Smith 8 Series, a hot water/steam oilfired boiler available in 8 sizes with efficiencies up to 86% AFUE Warranty Cast iron sections of Smith residential water boilers are covered by a limited lifetime warranty, prorated after the 10th year Steam boilers have a 10year warranty on cast iron sectionsSmith Cast Iron Boilers FurnaceCompare®