Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

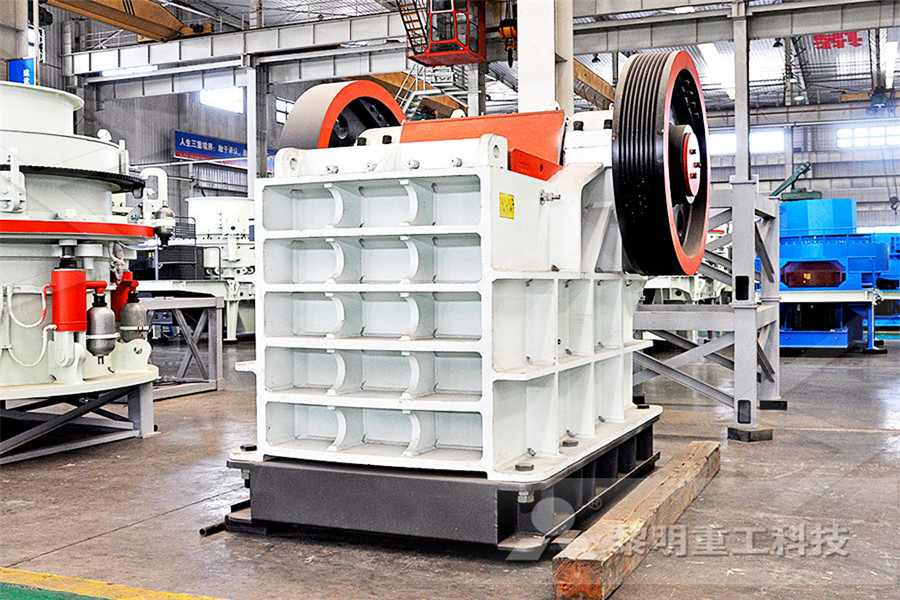

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Installed Capacity Of The Cement Mill Design

The majority of today's installed tube mills are used for grinding cement Besides cement, The dimensions and design of the mill shell, the mill heads and the mill bearings are basically, El no limitation in size and capacity of mill no delicateCONCRETE CAPACITY DESIGN (CCD) METHOD—EMBEDMENT DESIGN EXAMPLES 3492R3 d t = distance from center of tension force in anchors and adjacent edge of supported steel member, in e N′ = distance between resultant tension load on a group of anchors loaded in tension and theGuide to the Concrete Capacity Design (CCD) Method A 10 MW cement mill, output 270 tonnes per hour A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill Wikipediainstalled capacity of the cement mill desing; Latest Projects K Series Mobile Crushing Plant K Series Portable Crusher Plant, also known as K Series Portable Crusher, Crawler Mobile Crusher Crawler Mobile Crusher is a fully hydraulic tracktype mobile crusher developed and completed in order to satisfy higher user demandsinstalled capacity of the cement mill desinginstalled capacity of the cement mill desing in malawi Established in 1956 as Nyasaland Portland Cement the Company operates a Cement grinding mill in Blantyre and employes over 400 people Lafarge Cement Malawi is a subsidiary of the LafargeHolcim Group a global leader in building materials and solutions The Group has four business segments Cement Aggregates Ready Mix Concrete and installed capacity of the cement mill desing in malawi

installed capacity of the cement mill desing

installed capacity of the cement mill desingcement ball mill capacity design relaxacademynl cement ball mill design capacity calculation , Cement mill Wikipedia, the free encyclopedia A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its Calculate Ball Mill Grinding CapacityA) Total Apparent Volumetric Charge Filling installed capacity of the cement mill desing Second Hand Concrete Batching Plants For Sale In Malaysia Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligen Raw Complex Gold Ore Processing Machineinstalled capacity of the cement mill desingMill Feeders: Feeders will be directly installed under hoppers with rod gate in between The feeders are generally 2 to 3 m long and discharge on to a common conveyor which will take feed to mill Feeders for mills meter feed rates and also tantalize tons fed For cement mill feeding, table feeders, belt feeders, and weigh feeders have been usedCement Mill Feeding Cement Plant OptimizationThe mill is designed to handle a total ball charge of 3245 t at 100% loading with a percentage filling of 295% in both the chambers Both the chambers of the cement mill were charged with 80% of the designed charge, which works out to 86 t in Ist chamber and 172 t in the IInd chamberPROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL • Capacity increase of an existing production line from 2400 tpd to 3000 tpd Typical plant energy conservation projects: • Modification of the coal mill for operation with preheater exhaust gas for high volatile coal and utilization of 14 % RDF in the pyrosystem • Increase of efficiency and capacity of preheater, calciner and coolerPROFESSIONAL CEMENT PLANT OPTIMIZATION,

Guide to the Concrete Capacity Design (CCD) Method

basic concrete breakout strength of a postinstalled anchor in uncracked concrete without supplementary reinforcement to control splitting, in, see D86 c a,max = maximum distance from center of an anchor shaft to the edge of concrete, in c a,min = minimum distance from center of an anchor shaft to the edge of concrete, inSr No Name Of Unit : Province: Production Lines: As on June 2020: Operational Capacity: Clinker : Cement : 1 : Askari Cement Limited Wah : Punjab: 1: 1,050,000Installed Capacity All Pakistan Cement Manufecturars A userfriendly, highly transparent model for the design of postinstalled steel anchors or castinplace headed studs or bolts, termed the concrete capacity design (CCD) approach, is presented This approach is compared to the wellknown provisions of the American Concrete Institute (ACI) 34985CONCRETE CAPACITY DESIGN (CCD) APPROACH FOR FASTENING Region/Statewise Cement Capacity and Production in India (20092010) Selected Statewise Installed Capacity of Cement Plants in India (As on 30062010) Clusterwise Capacity, Production and Average Wagon Indented and Loaded per Day in India (20072008 and 20082009)Cement Capacity and Production India growth statistics Some of the company's capacity was idled until now Pioneer Cement expands grinding capacity by putting idled mills back to work, reports The Tribune Pakistan manufacturer Pioneer Cement was able Pioneer Cement expands capacity by enhancing installed mills Published on: 30 November 0001 Pioneer Cement expands capacity by enhancing installed mills

DESIGN OF ANCHOR BOLTS EMBEDDED IN CONCRETE MASONRY

For other anchor bolt configurations, including postinstalled anchors, design loads are determined from testing a minimum of five specimens in accordance with Standard Test Methods for Strength of Anchors in Concrete and Masonry Elements, ASTM E488 (ref concrete failure is always brittle, reinforced concrete design assumes that concrete has no tensile strength become decisive due to the low tensile capacity of the concrete PostInstalled Reinforcement Approvals Basics, design and installation of postinstalled rebars 10 / 2012 Anchor Fastening Technology Manual 09 / 2012DMP construction methods vary depending on projectspecific conditions, but are generally installed by: 1) advancing the steel casing to a predetermined design depth using rotarywash or compressedair drilling methods, 2) filling the casing with grout, 3) inserting a central threaded bar through the grout, and 4) withdrawing the casing to Deep Foundation and Pile Techniques Helical DrillingWith ~509 million tonnes per year (mtpa) of cement production capacity as of March 2019, India is the second largest cement producer in the world and accounts for over 8% of the global installed capacity As of July 2019, the production of cement stood at 281 million tonnes The cement production capacity is estimated to touch 550 MT by 2020Indian Cement Industry Report Cement Sector Research The Indian Cement Industry has an installed capacity of approximately 545 million tonnes comprising over 250 large cement plants Swachhata hi seva campaign CMA's active participation with the Government of India Download EBook New Investments, New Frontiers In 2010, the Indian Cement Industry’s share of India’s total CO2 emission was CMA India Cement Manufacturers Association in India

Evaluating the Performance of PostInstalled Mechanical

2116 Uncracked concrete—In these tests, concrete elements that are expected to remain uncracked unless the crack is part of the anchor failure mode 2117 Undercut anchor—A postinstalled anchor that derives its tensile holding strength by the mechanical interlock provided by undercutting the concrete, achieved either by a speA concrete anchor is a steel shaft either cast into concrete at placement or postinstalled after the concrete has hardened Castin anchors are threaded shafts with a buried end termination of a hex head, threaded nut, or 90° (L) or 180° (J) hook, or headed (nonthreaded) studs welded to a surface plateAnchoring To Concrete PDHonlineduced the concrete capacity design (CCD) method, which is the basis of the ACI 318 Appendix D provisions Neal S Anderson, PE, SE Consultant because a rational design method for postinstalled anchors was needed Postinstalled anchors are those that are installed in hardened concrete The need for these requirements wasA Review of HeadedStud Design Criteria in the Sixth anchors and postinstalled mechanical anchors installed in uncracked concrete that developed a full concrete cone at failure The CCD equation, used to predict the tensile capacity of a single anchor installed in uncracked concrete, is as follows 8: Ncone = 15 k f ck h ef (7) where, Ncone = mean tensile strength of concrete cone, NBehaviour of grouted anchors Structural Engineersduced the concrete capacity design (CCD) method, which is the basis of the ACI 318 Appendix D provisions Neal S Anderson, PE, SE Consultant because a rational design method for postinstalled anchors was needed Postinstalled anchors are those that are installed in hardened concrete The need for these requirements wasA Review of HeadedStud Design Criteria in the Sixth

Evaluating the Performance of PostInstalled Mechanical

2116 Uncracked concrete—In these tests, concrete elements that are expected to remain uncracked unless the crack is part of the anchor failure mode 2117 Undercut anchor—A postinstalled anchor that derives its tensile holding strength by the mechanical interlock provided by undercutting the concrete, achieved either by a speIn the United States, headed stud anchorage design usually followed procedures set forth in the PCI Handbook 2 or the nuclear structures code of ACI Committee 3493 The Concrete Capacity Design (CCD) approach for anchorage to concrete has recently been approved as Chapter 23 of the upcoming 2002 version of the ACI 318 Building Code4, 5STEEL CAPACITY OF HEADED STUDS LOADED IN SHEARSome of the company's capacity was idled until now Pioneer Cement expands grinding capacity by putting idled mills back to work, reports The Tribune Pakistan manufacturer Pioneer Cement was able Pioneer Cement expands capacity by enhancing installed mills Published on: 30 November 0001 Pioneer Cement expands capacity by enhancing installed millsFor other anchor bolt configurations, including postinstalled anchors, design loads are determined from testing a minimum of five specimens in accordance with Standard Test Methods for Strength of Anchors in Concrete and Masonry Elements, ASTM E488 (ref DESIGN OF ANCHOR BOLTS EMBEDDED IN CONCRETE MASONRY concrete failure is always brittle, reinforced concrete design assumes that concrete has no tensile strength become decisive due to the low tensile capacity of the concrete PostInstalled Reinforcement Approvals Basics, design and installation of postinstalled rebars 10 / 2012 Anchor Fastening Technology Manual 09 / 2012

Foundation Support Cost: Applications to DrivenPile Design

Pile Support Cost: Design Efficiency Installed Cost = $5,000 Allowable Pile Load = 250T Structure Design Load = 700T T Structure Design Load = 300 $ 5,000 250T 700 Large Resisted Loads Small Resisted Loads 3 x $5,000 $ T 3 x 300T $2000 per available ton $ = 5000 per structure$ design ton 2143 per structure design tonA concrete anchor is a steel shaft either cast into concrete at placement or postinstalled after the concrete has hardened Castin anchors are threaded shafts with a buried end termination of a hex head, threaded nut, or 90° (L) or 180° (J) hook, or headed (nonthreaded) studs welded to a surface plateAnchoring To Concrete PDHonlineWith ~509 million tonnes per year (mtpa) of cement production capacity as of March 2019, India is the second largest cement producer in the world and accounts for over 8% of the global installed capacity As of July 2019, the production of cement stood at 281 million tonnes The cement production capacity is estimated to touch 550 MT by 2020Indian Cement Industry Report Cement Sector Research PROCEDURES FOR DESIGN, CONSTRUCTION AND INSTALLATION OF INTERCEPTORS AND SEPARATORS (APPENDIX M IS A REQUIREMENT OF THIS CODE) M101 GENERAL The provisions of this appendix shall apply to the design, construction, installation and testing of interceptors and separators required in accordance with 1004 M1033 Pri M102 DEFINITIONSPROCEDURES FOR DESIGN, CONSTRUCTION AND Dec 04, 2020 The Indian cement industry is dominated by a few companies The top 20 cement companies account for almost 70 per cent of the total cement production in the country A total of 210 large cement plants account for a cumulative installed capacity of over 410 MT, with 350 small plants accounting for the restCement Industry in India, Indian Cement Industry, Sector

STRUCTURE magazine Using Software to Control Anchor Design

Concrete Capacity Design (CCD) has been a code methodology for anchor design since it was introduced directly into section 1913 of the 2000 International Building Code (IBC) It was initially a strength design option and was limited to castinplace anchors onlyAEFAC Technical Note TN0121213 Page 2 of 6 TECHNICAL NOTE: DESIGN CONCEPTS FOR POSTINSTALLED AND CASTIN ANCHORS Design action or design load – the combination of the nominal actions or loads and the load factors specified in AS/NZS 11700, AS/NZS 11701, AS/NZS 11702, AS/NZS 11703, AS 11704 or other standardsTECHNICAL NOTE: DESIGN CONCEPTS FOR POST Cement Corporation of India Limited (CCI) was incorporated as a Company wholly owned by Government of India on 18th January 1965 with the principal objective of achieving self sufficiency in cement production The authorised and paidup capital of the company is Rs 900 crores and Rs 81141 crores respectivelyCCI ::: Cement Corporation Of India Limited