Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

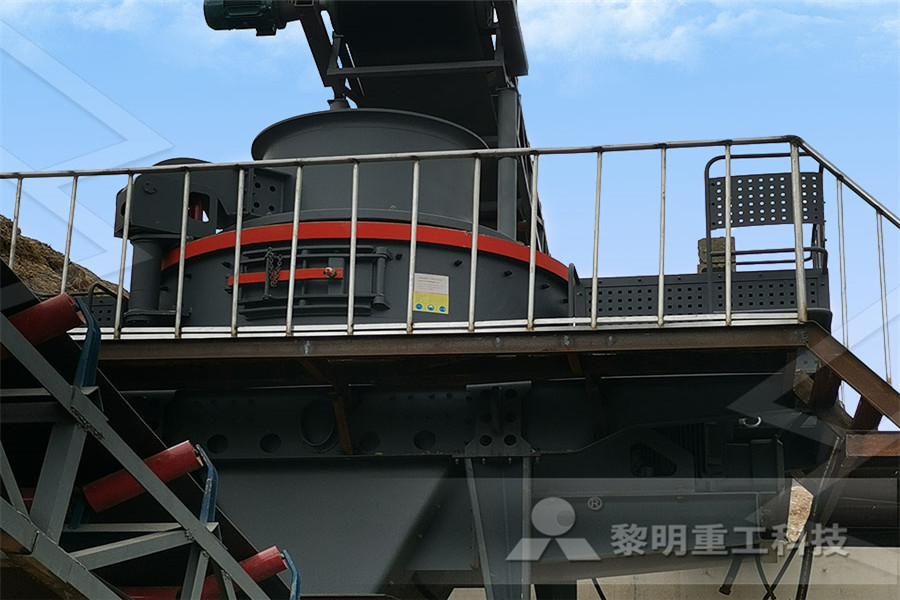

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Conveyors Maximum Inclinations for typical Products

150 rows Maximum conveyor slopes for various materials Related Topics Miscellaneous Engineering related topics like Beaufort Wind Scale, CEmarking, drawing standards and more; Related Documents Angle of Repose Tipping or dumping angles for some common materials like ashes, sand, earth, shingles ; Belt Transmissions Length and Speed of Belt Length and speed of belt and belt Founded by industry pioneer Joseph A Dos Santos, DSI has been advancing bulk material handling solutions since 1997 With the invention of and advances in Sandwich Belt High Angle Conveyors, the development and utilization of our Expanded Conveyor Technology, and most recently, the patented Adder Snake Conveyors, we’re engineering ideal solutions for some of the world’s most challenging DSI Sandwich Belt High Angle Conveyors Legacy of InnovationHI100 High Incline Conveyor HI100 High Incline Conveyor is used for steep inclined and vertical conveying HI100 High Incline Conveyor provides the advantage of going up in significantly smaller space than traditional belt conveyorHI100 High Incline Conveyor ROXONThere are a lot off suppliers providing inclined slope belt conveyor on okchem, mainly located in Asia The inclined slope belt conveyor products are most popular in India, Pakistan, Vietnam, Indonesia, Brazil, Russia, Mexico, United States, Turkey, Germany, etcinclined slope belt conveyor, inclined slope belt conveyor A high angle conveyor can be defined as any conveyor that transports material along a slope exceeding the dynamic stability angle of the transported material The application of conveyors in this mine study recognises the cost savings in material haulage that a high angle conveyor has in a total system High Angle Conveyor PrinciplesHigh Angle Conveyor Offers Mine Haulage Savings

Innovative Engineering Design of the HighAngle Conveyor

The use of a steep belt conveyor in these conditions will improve the efficiency of the systems of cyclic flow technology (CFT) In comparison with traditional conveyors, inclined conveyors are able to move bulk materials at an angle of 5060° or moreAs the conveyor slopes up, the cleats on the conveyor belt create shelves to support the product until it reaches the top of the slope Cleated conveyor belt provides for suitable work support in transferring of goods in areas like ports, mine, foundry, food supplies, fertilizers, and othersConveyors – Welcome to ZULTEC Group* Maximum 20” (508) cleat spacing for 18” and wider conveyors with lengths greater than 7’ (2134) ** 18” and wider conveyors have a maximum length of 7’ (2134) Base Belt Material: 055 in (14 mm) thick, high friction FDA approved urethane, 176˚F (80˚C) maximum part temperature See Specialty Belt 67 for low friction base belt materialDorner Conveyor Belting Options Dorner ConveyorsIncline belt conveyors feature a center drive, gear motor, and takeup with a single or double nose And instead of using a smoothsurfaced belt, this type of conveyor has a rough surface on the belt, ideal for carrying products up or down8 Basic Types of Conveyor Belts and Their Applications Belt conveyors slopeHigh slope belt conveyor crusher usaXsm is a professional types of slope angle belt conveyors wikipedia manufacturer in china the slope angle belt conveyors wikipedia machine produced by our company have different types including raymond millball millgrindingChat online sloping conveyors for angled conveyor on slope cSlope Angle Belt Conveyors Wikipedia

Incline Conveyors CiscoEagle

A much higher load weight capacity than slider bed conveyors due to reduced belttobed friction Conveyor also has a channeled frame equipped with a single transition roller on the end of the conveyor bed Load per linear ft: 225 lbs max Available in overall widths of 18", 24", and 30"Frazier Son’s new line of Incline Conveyors are designed for highend food and packaging applications These robust stainless steel/sanitary constructed conveyors are designed with innovative quick release foldout side boards and belt lifters to raise the belt Incline Conveyors Frazier SonAshland Telescopic Conveyors extend so easily that a 5 section unit with 3" slope per 10' will extend itself on a smooth floor The package stop also serves as a handle to extend and retract the conveyor Durability is another reason our product is preferred The main frame stringers are made from 7 ga steelTelescoping Conveyor at Ashland Conveyor ProductsAs the conveyor slopes up, the cleats on the conveyor belt create shelves to support the product until it reaches the top of the slope Cleated conveyor belt provides for suitable work support in transferring of goods in areas like ports, mine, foundry, food supplies, fertilizers, and othersConveyors – Welcome to ZULTEC Group* Maximum 20” (508) cleat spacing for 18” and wider conveyors with lengths greater than 7’ (2134) ** 18” and wider conveyors have a maximum length of 7’ (2134) Base Belt Material: 055 in (14 mm) thick, high friction FDA approved urethane, 176˚F (80˚C) maximum part temperature See Specialty Belt 67 for low friction base belt materialDorner Conveyor Belting Options Dorner Conveyors

Conveyor Designers Concentrate on Safe, Highcapacity

Conveyors serve as the arteries for coal mines Once raw coal is cut from the face, it’s loaded onto a network of conveyors that funnel it to a mainline slope belt that eventually delivers it to the surface where another set of overland conveyors brings it to the prep plantIncline belt conveyors feature a center drive, gear motor, and takeup with a single or double nose And instead of using a smoothsurfaced belt, this type of conveyor has a rough surface on the belt, ideal for carrying products up or down8 Basic Types of Conveyor Belts and Their Applications Cambelt specializes in engineering closed and high incline conveyor belt systems in straight, L, and Z configurations to meet our customer’s sitespecific requirement Our systems are environmentally friendly as our conveyors High Incline Closed Conveyor Belts Cambelt InternationalA much higher load weight capacity than slider bed conveyors due to reduced belttobed friction Conveyor also has a channeled frame equipped with a single transition roller on the end of the conveyor Incline Conveyors CiscoEagleFrazier Son’s new line of Incline Conveyors are designed for highend food and packaging applications These robust stainless steel/sanitary constructed conveyors are designed with innovative quick release foldout side boards and belt lifters to raise the belt Incline Conveyors Frazier Son

Dorner Conveyor Belting Options Dorner Conveyors

* Maximum 20” (508) cleat spacing for 18” and wider conveyors with lengths greater than 7’ (2134) ** 18” and wider conveyors have a maximum length of 7’ (2134) Base Belt Material: 055 in (14 mm) thick, high friction FDA approved urethane, 176˚F (80˚C) maximum part temperature See Specialty Belt 67 for low friction base belt Slope Conveyor Wholesale Various High Quality Slope Conveyor Products from Global Slope Conveyor Suppliers and Slope Conveyor FactoryImporterExporter at Alibaba Tags Sloping Mini Conveyor Belts Stainless Steel Chain Link Conveyor Belt Energy Saving Slope Belt Conveyor Hansestadt DemminAbout High Temperature Belts High temperature conveyor belts are usually made by mixing rubber with high temperature resistant materials such as EP or PTFE They typically have a cotton, canvas High Temperature Conveyor Belts Heat Resistant TeflonAce The belt roll has been handled as previously described The rope or cable is then threaded over the conveyor and attached to a towing device to pull the belt onto the conveyor For installations with a relatively high degree of slope (12 degrees or more), the method of handling is slightly different The roll of belt Installation – A1 CONVEYORSa belt clamp, mounted on the conveyor structure, through which the belt is threaded Where the slope is very long, additional clamps should be spaced approximately 1000 feet apart Where more than one clamp is used, workers are stationed at each clamp to loosen and tighten the clamps as the belt is fed onto the conveyorConveyor Belt Installation, Maintenance Troubleshooting