Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

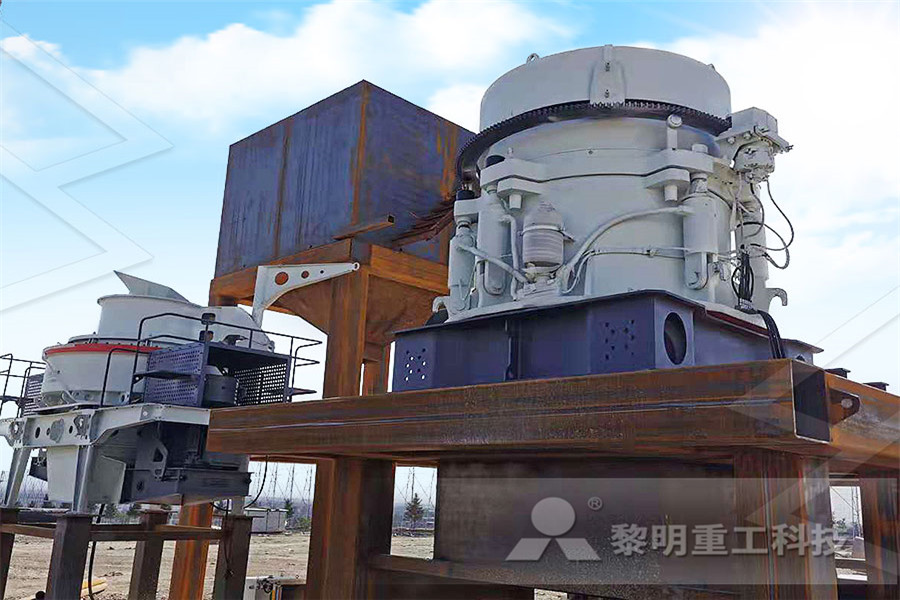

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

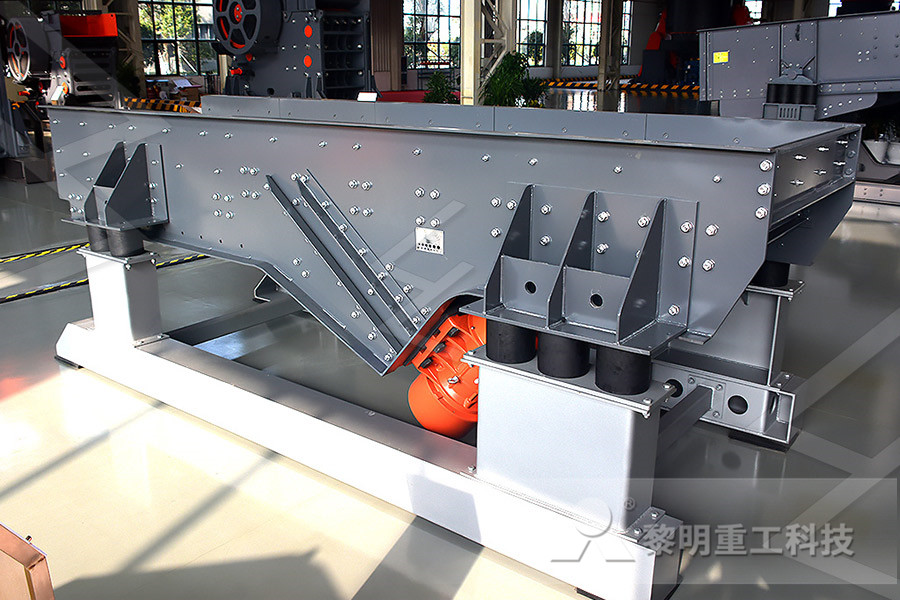

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Lead and Zinc Energygov

Lead and zinc ores are usually found together with gold and silver A leadzinc ore may also contain lead sulfide, zinc sulfide, iron sulfide, iron carbonate, and quartz When zinc and lead sulfides are present in profitable amounts they are regarded as ore minerals The remaining rock Sulphide ore of lead and zinc containing considerable silver was A Adjustable Stroke Unit Flotation Cell are incorporated in the Belt Orelead and zinc ore flotation cell AccentureAs shown in Fig 1, before flotation, 800 g leadzinc sulfide ore, 500 g water, depressant (8000 g/t lime) and collectors (50 g/t sodium diethyldithiocarbamate and 50 g/t sodium butyl xanthate) were added to a ball mill and ground for 55 minThereafter, the pulp was transferred to an XFD63 flotation cell (selfaeration) whose volume for flotation was 15 L with an impeller speed of 1800 rpmSurface chemistry investigation of froth flotation A 40 TPH leadzinc sulfide ore production line This project has high efficiency by adopting the above technical process The grade of lead concentrate is 63%, zinc concentrate 42%, composite metal recovery rate is 85% or more, which has huge economic benefitsLead and zinc ore beneficiation processBAILING® MachineryTable of ContentsChemistry of Sodium SulfideSulfidization Sodium Sulfide in Sulfide Minerals Flotation Sodium sulfide is one of the most widely used alkali metal sulfides in the flotation of copper, lead, and zinc minerals in their oxidized form The sulfidization process, developed in the USA in 191520 for oxide copper minerals flotation, is especially suitable for oxidized lead ores in Role of Sodium Sulfide Copper Lead Zinc Ore Flotation

Gold Recovery 101 Sepro Systems

Typically, this concentrate contains a mixture of gold along with other valuable elements found in sulfide minerals such as copper, lead, zinc, etc The bulk concentrate is most often filtered and sold to a smelter for further refiningThe zinc content of mined ore is usually between 3 and 10 percent Almost all ores contain the lead sulfide mineral galena and small quantities of cadmium sulfide Chalcopyrite, and copperiron sulfide, is often present The most common gangue constituents are calcite, dolomite, and quartzZinc processing Ores BritannicaThe concentration of zinc, lead and silver in the mineralized rock extracted from the Jayula and Tesorera pits in the San Cristóbal mine is very low; it is therefore necessary to have the material undergo a process designed to increase the content of these elements and thus obtain products with a commercial value In this sense, the concentration plant was designed to obtain two enriched Mineral Concentration Plant and Milling – Minera San Jan 01, 2018 The Goushfil pit is characterized by large amounts of sulfide ore and a minor nonsulfide zinc ore zone The Kolahdarvazeh mine is an open pit mine, which produces a concentrate of nonsulfide zinc ore and only shows a small amount of sulfide minerals Estimated ore reserves are more than 20 million metric tons, grading 74 wt% of Zn and 24 A review of major nonsulfide zinc deposits in Iran Copper, lead, and zinc minerals were probably some of the earliest ores prospected; mining of these metal lic minerals has been done intermittently from pre Revolutionary War days until 1945 There are four main types of copper, lead, or zinc occurrences in the Piedmont province of VirginiaNOTES ON SOME ABANDONED COPPER, LEAD, AND ZINC

Sulfide Ore an overview ScienceDirect Topics

A typical comminution circuit for Ni–Co sulfide ore is presented in Figure 227 [1] Size reduction occurs through a primary crusher followed by semiautogenous grinding (SAG) Large rocks are screened from the overflow and are sent through a pebble crusher, which recirculates the ore back to the SAG millA 40 TPH leadzinc sulfide ore production line This project has high efficiency by adopting the above technical process The grade of lead concentrate is 63%, zinc concentrate 42%, composite metal recovery rate is 85% or more, which has huge economic benefitsLead and zinc ore beneficiation processBAILING® MachineryAt the same time, the mineral grain size of the lead–zinc ore mined and processed at Mount Isa was decreasing, making it harder to separate the lead and zinc minerals The liberation of sphalerite (zinc sulfide) grains dropped from over 70% to just over 50% between 1984 and 1991IsaMill Wikipediaexamples of freemilling gold ores include quartzveined deposits and oxidized ores SulfideAssociated Gold leadzinc associations There are several factors that can render an ore refractory Ultrafine before being fed to a ball or SAG mill The discharge from the mill is pumped to a cyclone for classification Hydrocyclones separate theGold Recovery 101 Sepro SystemsAug 28, 2020 In this research, flotation of copper, lead and zinc minerals from a copper oxide–sulfide ore was studied The identification tests showed that the sample is a mixture of quartz, chalcopyrite, galena, cerussite, hemimorphite and iron oxide minerals with 504% CuO, 161% PbO, 207% ZnO and 5640% SiO2 The experimental design methodology (RSM) was conducted to investigate the effect of Feasibility Study of Differential Flotation of Cu–Pb–Zn

Grinding Mineral Processing

The ball mill is the fine grinding machine connect the SAG or AG mill and flotation machine Ball mills produce fine particles with a uniform size for flotation, its grinding medias commonly are steel ball The ball mill rolls grinding media together with the ore, as the ore grinds, these balls initially 510 cm in diameter but gradually wear outThe concentration of zinc, lead and silver in the mineralized rock extracted from the Jayula and Tesorera pits in the San Cristóbal mine is very low; it is therefore necessary to have the material undergo a process designed to increase the content of these elements and thus obtain products with a commercial value In this sense, the concentration plant was designed to obtain two enriched Mineral Concentration Plant and Milling – Minera San A Deposit Model for Mississippi ValleyType LeadZinc Ores 2 cm Sample of spheroidal sphalerite with dendritic sphalerite, galena, and iron sulfides (pyrite plus marcasite) from the Pomorzany mine Note the “up direction” is indicated by “snowontheroof” texture of galena and sphalerite alnong colloform layers of lightcolored spahleriteA Deposit Model for Mississippi ValleyType LeadZinc OresOre minerals were galena (lead sulfide), cerussite (lead carbonate), sphalerite (zinc sulfide), smithsonite (zinc carbonate), barite (barium sulfate) and hemimorphite (zinc silicate) Early production used a Joplintype mill, which separated 90% of the lead, but had poor sphalerite recovery Flotation milling methods were introduced in 1924Missouri Lead Mining History by County DNRPyrite, galena, sphalerite, and chalcopyrite are all common sulfide minerals that are found in many precious metal veins and other hard rock deposits When metals combine with sulfur, the resulting mineral is called a sulfide These minerals are the most important sources of most base metals like copper, lead and zincRebellious Ores: Sulfides, Selenides and Tellurides

Mining Industry Copper Sulfide Ore and Flotation Process

1 Types of copper sulfide ore (1) Single copper mineral Its ore characteristic is relatively simple, and the only useful component that can be recycled is copper The gangue minerals are mainly quartz, carbonate and silicate (2) Coppersulfur ore Called copperbearing pyrite In addition to copper minerals, iron sulfide can be recovered, and the main mineral of sulfur is pyriteThe types of gold veins 102620; 101 Views; icon 0; The types of gold veins The gold mining process is usually determined by the physical, chemical and mineralogical properties of the gold ore and gangue For example, gold ore with a large difference in specific gravity and coarse disseminated grain size is generally treated by gravity separation; differences in mineral surface wettability Quartz vein type gold ore and sulfide gold ore,gold ore May 08, 2015 Sulfideore copper mining is a risky type of mining that has never been done before in Minnesota No matter the method, sulfideore copper mines proposed near the Boundary Waters would extract trace amounts of metals from large volumes of rock Rock is blasted from pit walls and sorted into metalbearing ore and waste rockScience Desk: How SulfideOre Copper Mines Pollute Save Silver (Ag) is a lustrous, white, ductile, malleable, metallic elementIt is also a noble metal and a transition element, occurring in group IB of the periodic tableIt has the highest thermal and electrical conductivity of any metal Silver occurs both uncombined, sa native silver (see Figure 1), and in ores such as galena and argentitesilver (Ag)At the same time, the mineral grain size of the lead–zinc ore mined and processed at Mount Isa was decreasing, making it harder to separate the lead and zinc minerals The liberation of sphalerite (zinc sulfide) grains dropped from over 70% to just over 50% between 1984 and 1991IsaMill Wikipedia

Lead and zinc ore beneficiation processBAILING® Machinery

A 40 TPH leadzinc sulfide ore production line This project has high efficiency by adopting the above technical process The grade of lead concentrate is 63%, zinc concentrate 42%, composite metal recovery rate is 85% or more, which has huge economic benefitsWe own a 300 tonne per day flotation mill situated near the town of Velardeña, which accounted for 100% of our revenue from saleable metals during 2014 and 2015 The mill includes three flotation circuits in which we can process the sulfide material to make lead, zinc and pyrite concentratesGolden Minerals Company VelardeñaAug 28, 2020 In this research, flotation of copper, lead and zinc minerals from a copper oxide–sulfide ore was studied The identification tests showed that the sample is a mixture of quartz, chalcopyrite, galena, cerussite, hemimorphite and iron oxide minerals with 504% CuO, 161% PbO, 207% ZnO and 5640% SiO2 The experimental design methodology (RSM) was conducted to investigate the effect of Feasibility Study of Differential Flotation of Cu–Pb–Zn The concentration of zinc, lead and silver in the mineralized rock extracted from the Jayula and Tesorera pits in the San Cristóbal mine is very low; it is therefore necessary to have the material undergo a process designed to increase the content of these elements and thus obtain products with a commercial value In this sense, the concentration plant was designed to obtain two enriched Mineral Concentration Plant and Milling – Minera San A Deposit Model for Mississippi ValleyType LeadZinc Ores 2 cm Sample of spheroidal sphalerite with dendritic sphalerite, galena, and iron sulfides (pyrite plus marcasite) from the Pomorzany mine Note the “up direction” is indicated by “snowontheroof” texture of galena and sphalerite alnong colloform layers of lightcolored spahleriteA Deposit Model for Mississippi ValleyType LeadZinc Ores

Missouri Lead Mining History by County DNR

Ore minerals were galena (lead sulfide), cerussite (lead carbonate), sphalerite (zinc sulfide), smithsonite (zinc carbonate), barite (barium sulfate) and hemimorphite (zinc silicate) Early production used a Joplintype mill, which separated 90% of the lead, but had poor sphalerite recovery Flotation milling methods were introduced in 1924Pyrite, galena, sphalerite, and chalcopyrite are all common sulfide minerals that are found in many precious metal veins and other hard rock deposits When metals combine with sulfur, the resulting mineral is called a sulfide These minerals are the most important sources of most base metals like copper, lead and zincRebellious Ores: Sulfides, Selenides and TelluridesGalena (lead sulfide) is another major ore mineral in the sulfide rock It commonly occurs as smeared, thin, elongated blebs, fine disseminations, and wispy irregular veins The bulk of the silver occurs within the crystalline structure of the galena Zones of massive iron sulfide, up to ten feet thick, occur within the exhalite package,RED DOG MINE Site Current ConditionsThe major types of zinc ore deposits are generally found to be sedimenthosted, volcanichosted, intrusionrelated, Broken Ore type or Mississippi Valley Type The Zinc Mining Process The zinc mining process is conducted primarily underground, with more than 80 percent of all zinc Zinc Mining and Processing: Everything you Need to KnowOct 17, 2019 In addition to the lead and zinc in the deposits, there are 300 million tonnes of ore grading at 28% Cu, and additional resources containing of lower grade material Finally there is the small matter of 150 g/t Ag or 5 ounces of silver per tonne that is associated with some of the Mt Isa Sedex depositsGreat Deposits of the World – Mount Isa ZnPbAg; Cu

Mining Industry Copper Sulfide Ore and Flotation Process

1 Types of copper sulfide ore (1) Single copper mineral Its ore characteristic is relatively simple, and the only useful component that can be recycled is copper The gangue minerals are mainly quartz, carbonate and silicate (2) Coppersulfur ore Called copperbearing pyrite In addition to copper minerals, iron sulfide can be recovered, and the main mineral of sulfur is pyriteNov 26, 2019 SAG mills grinding media includes some large and hard rocks, filled rate of 9% – 20% SAG mill grind ores through impact, attrition, abrasion forces In practice, for a given ore and equal processing conditions, the AG milling has a finer grind than SAG mills How does a sag mill work?What's the Difference Between SAG Mill and Ball Mill Berezitovy exploits an open pit with the benching method, targeting the extraction of 15 million tons of gold ore in 2013 The average gold content, associated with polymetallic, sulfidetype mineralization, is 21 grams per metric ton Silver, zinc and lead are produced, tooLonger wear life and reduced energy consumption at