Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

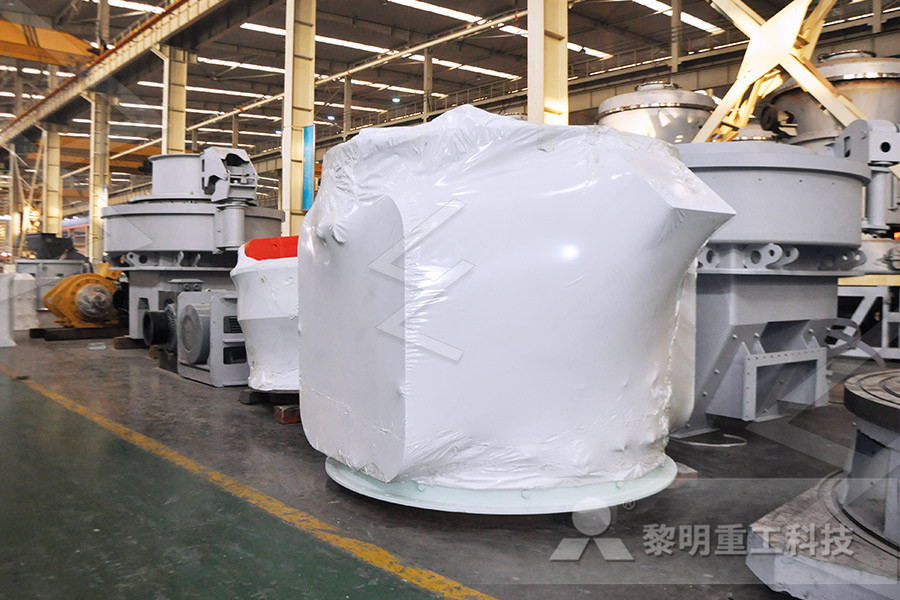

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Manufacturer And Working Principle Of Coal Vertical Roller

Our new vertical roller mill equipment has scientific working principle, high pulverizing efficiency and grading efficiency It is a special equipment for efficient production of coal mine stone grinding project Advantages and features of HCM coal vertical roller mill Pulverized coal is flammable and explosive, and has high application valueVertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms, but it works basically the sameVertical roller mill WikipediaThe Design Principle of Vertical Roller Mill Posted: The past two years, the popularity of vertical roller mill is growing Vertical roller mill, is vertical mill for short, is a grinding processing equipment dealing with raw material such as cement, cement clinker, slag and cinderThe Design Principle of Vertical Roller MillRoller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and othersRoller grain mills are an alternative to traditional millstone arrangements in gristmillsRoller mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the Roller mill WikipediaThe Working Principle Of Vertical Roller Mill Vertical Roller Mill working principle The air selected airflow of the Vertical Roller Mill is circulated and flowed in the fan mdash mill shell mdash cyclone separator mdash therefore, it has less dust than the high speed centrifugal pulverizer, the operation workshop is clean, the environment is non polluting, and the productWorking Principle Of Vertical Roller Mill Operation Losch

Vertical Roller Mills

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and Vertical roller working principleWorking principle of three roller mill stanvandongenImportant for an engineer to know the basic design, working principle and operation of industry and operation and use of various rolling mill equipment and systems provided by333 elevation of a three stand tandem cold strip millworking principle of three roller millprinciple of a vertical roller mill equipment The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe principle of vertical roller mill ME Mining Machineryvertical roller mill working principle Second Hand Concrete Batching Plants For Sale In Malaysia Abstract: Ore Surface Processing Equipment has been a technical difficulty, the market demand for a wide large equipment, along with India#8217;s growing procevertical roller mill working principleComparison Grinding Principle of Ball Mill and Vertical By contrast, the principle of the vertical mill is to apply forces to a thin material bed, which lies between the mill table and the rollers The high pressure forces, supplied by a hydraulic system on the rollers, cause the individual particles within the bed to fracture This type of grinding is much more efficient than the ball mill principle of vertical grinding mills

Vertical Roller Mill

Working Principle of Vertical Roller Mill The grinding disc is driving by motor through reducer The material falls to grinding disc from the feed opening The materials are driven to the edge of disc by the centrifugal force and crushed into fine powders by rollersvertical roller mill working principle vertical Vertical Roller Mill,Working Principle Of Vertical Roller Mill A vertical roller mill is a type of industrial equipment used to crush or grind materials into small vertical roller mill working principle verticalprinciple of vertical roller mill The design principle of vertical roller mill the design principle of vertical roller mill posted the past two years, the popularity of vertical roller mill is growing vertical roller mill, is vertical mill for short, is a grinding processing equipment dealing with raw material such as cement, cement clinker, slag and cinderGet pricecement vertical roller mill working principleThe Working Principle Of Vertical Roller Mill Vertical Roller Mill working principle The air selected airflow of the Vertical Roller Mill is circulated and flowed in the fan mdash mill shell mdash cyclone separator mdash therefore, it has less dust than the high speed centrifugal pulverizer, the operation workshop is clean, the environment is non polluting, and the productWorking Principle Of Vertical Roller Mill Operation Loschprinciple of a vertical roller mill equipment The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts FOR principle vertical roller mill MC World

Grain Roller Mills Grain Processing Equipment

Depend on Automatic Equipment Manufacturing’s high capacity roller mills in either the ATG 10000 or 15000 models, which can process 10 thousand or 15 thousand bushels per hour, respectively Automatic’s topoftheline grain processing equipment can have a principle of a vertical roller mill equipment The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe principle of vertical roller mill ME Mining Machineryvertical roller mill working principle Second Hand Concrete Batching Plants For Sale In Malaysia Abstract: Ore Surface Processing Equipment has been a technical difficulty, the market demand for a wide large equipment, along with India#8217;s growing procevertical roller mill working principleComparison Grinding Principle of Ball Mill and Vertical By contrast, the principle of the vertical mill is to apply forces to a thin material bed, which lies between the mill table and the rollers The high pressure forces, supplied by a hydraulic system on the rollers, cause the individual particles within the bed to fracture This type of grinding is much more efficient than the ball mill principle of vertical grinding millsprinciple of vertical roller mill ME Mining Machinery principle of vertical roller mill Working principle of Vertical Roller Mill: The grinding disc is driving by motor through reducer The material falls to grinding disc from the feed opening The materials are driven to the edge of disc by the centrifugal force and crushed into fine roller principle triple pe pex jaw crusher

vertical roller mill working principle pdf

vertical roller mill working principle pdf There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and craftsmanship, adopting Hydraulic system vertical roller mill operation 3/25/2015 Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both working principle of vertical roller mill for coal MC WorldThe vertical roller mill is used to grind the material by using the principle of material bed pulverization It gathers materials for grinding, conveying, powder selection, drying and how to improve grinding efficiency of vertical roller millHLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process HLM Vertical Roller Mill Guilin HCM MachineryVertical Roller Mill working principle The airselected airflow of the Vertical Roller Mill is circulated and flowed in the fan mdash; mill shell mdash; cyclone separator mdash; therefore, it has less dust Vertical Roller Mill Working Principle

vertical roller mill working principle vertical

vertical roller mill working principle vertical Vertical Roller Mill,Working Principle Of Vertical Roller Mill A vertical roller mill is a type of industrial equipment used to crush or grind materials into small principle of vertical roller mill The design principle of vertical roller mill the design principle of vertical roller mill posted the past two years, the popularity of vertical roller mill is growing vertical roller mill, is vertical mill for short, is a grinding processing equipment cement vertical roller mill working principleprinciple of vertical roller mill equipment Vertical roller mill has many different forms, but it works basically the same All of these forms of machine come with a roller (or the equivalent of roller grinding parts), and roller along the track of the disc at the level of circular movement imposed by external grinding roller in the vertical principle of vertical roller mill equipment ME Mining