Solutions

Products

-

Primary mobile crushing plant

-

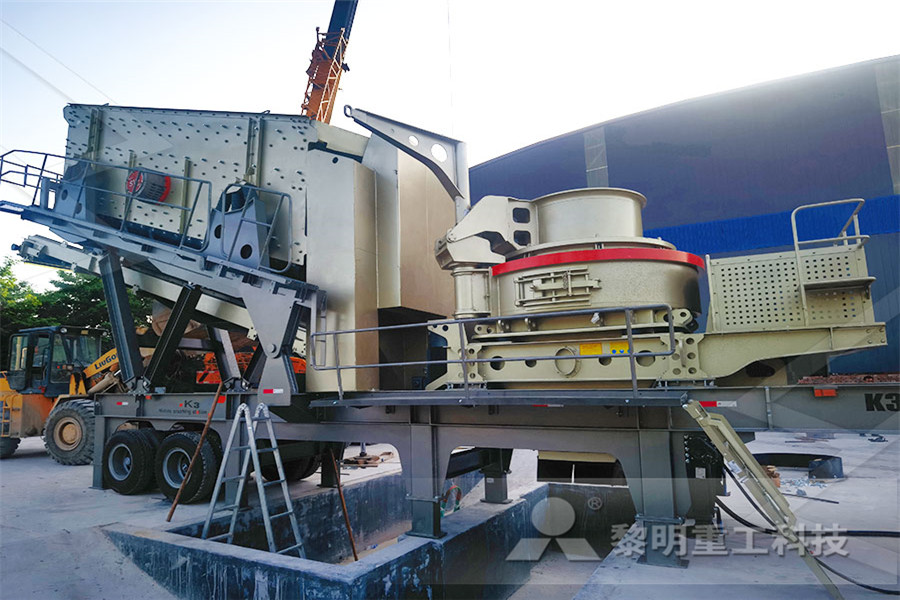

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Mill Steel Charge Volume Calculation

We can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media While the mill is stopped, the charge volume can be gotten by measuring the diameter inside the liners and the distance from the top of the charge to the top of the mill The % loading or change volume can then be read off the graph below or Calculation for filling of grinding media charge Mill Steel Charge Volume Calculation Jun 19, 2015 We can calculate the steel charge volume of a ball or rod mill and express it as the of the volume within the liners that is filled with grinding media While the mill is stopped, the charge volume can be gotten by measuring the diameterGrinding Mill Filling CalculationsThe correct estimate of grinding charge (form and dimensions of the grinding media, loading specific charge of the drum, report between quantity of material and the quantity of grinding charge, etc), influence in a determining degree the efficiency of the mill work (grinding fineness, wear of grinding media, throughput of the mill, energy specificconsumption, noise produced by the mill, etc)THE GRINDING CHARGE OF ROTARY MILLScalculation for filling of grinding media charge To calculate grinding media charge for continuous type ball mill, M = 0 x D2 x L Example To calculate grinding media charge for a 180 cm dia x 180 cm long batch type ball mill with Duralox 50 mm thick bricks Formula to be used is M = 0 x D2 x L D = 180 10 = 170 cms Get pricecalculation of material charge for a ball grinding machine The basic principle is to measure the height ‘H’ from the charge to the shell and the internal mill diameter ‘Di’ By calculating the ratio ‘H/Di’ and using the graph below (Figure 1), the charge filling degree in volume could be estimatedOptimization of mill performance by using

TECHNICAL NOTES 8 GRINDING R P King

The effect of mill charge is primarily through the shifting of the center of gravity and the mass of the charge As the charge increases the center of gravity moves inward The power draft is more or less symmetrical about the 50% value A simple equation for calculating net How to calculate the filling amount of grinding media Sand mill can be used glass ball, zirconia balls, steel ball for grinding media, each medium is best to use a uniform particle size into the cylinder before the media should be cleaned in advance, screeningGrinding with a certain medium to be based on the fineness of the material to be polished and viscosity to chooseget priceceramic grinding media balls calculationIn Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner wear and Calculate and Select Ball Mill Ball Size for Optimum GrindingDec 08, 2009 Re: how to estimate the wear rate for Ball mill Most practical way to by measuring empty height and calculating the % volumetric filling of grinding mediaAlternative way to make track of mill main drive kW consumption reduction and add makeup charge how to estimate the wear rate for Ball mill Page 1 of 10A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill Wikipedia

CALCULATION OF THE FILLING DEGREE THE BALL MILL WITH

Apr 28, 2020 In January this year, we launched a new service on our website Therefore, for those of you who don’t know it yet, we recall that this service is intended for calculation of the filling degree the ball mill with grinding media You will receive accurate calculation of the filling degree the ball mill with grinding media at the following link and by filling in the proper fields as quickly as Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to improve the mill efficiency:Ball charges calculators thecementgrindingofficeSep 01, 2004 In addition, the charge position must be such that the grinding media hits the charge toe and not the liners Therefore, a reliable online volumetric charge measurement is vital in the control and optimization of a grinding mill (Marklund and Oja, 1996; Dupont and Vien, 2001; van Nierop and Moys, 2001; Tano et aI, 2003) y, 90 x, o Charge A Volumetric Charge Measurement for Grinding Mills Table I illustrates or quantifies the media charge angle for different liner designs at different mill speed but with constant filling degree (30%) Indeed, as explained previously, at a mill stop, the measurement of ball charge filling degree could be undertaken and will provide the static media charge angle (βstatic = 143°) An online Optimization of mill performance by usingThe effect of mill charge is primarily through the shifting of the center of gravity and the mass of the charge As the charge increases the center of gravity moves inward The power draft is more or less symmetrical about the 50% value A simple equation for calculating net TECHNICAL NOTES 8 GRINDING R P King

A Method to Determine the Ball Filling, in Miduk Copper

The results obtained from this work show, the ball filling percentage variation is between 12– 37% which is lower than mill ball filling percentage, according to the designed conditions (15%) In addition, acquired load samplings result for mill ball filling was 13% Keywords: Miduk Copper oncentrator, SAG Mill, Ball Filling PercentageGrinding Media The bulk densities of the steel media typically used are: Balls 4650 kg/m 3 Cylpebs 4700 kg/m 3 Rods 6247 kg/m 3 Cubes 5500 kg/m 3; For soft ore, ceramic media (90 °/o A l 2 0 3) can be used (2200 kg/m 3) Grinding media [images: mill media (13577)]AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner wear and Calculate and Select Ball Mill Ball Size for Optimum GrindingJan 07, 2015 2 Shape, size, and weight of the grinding media 3 Friction between the lining and the grinding media 4 Internal friction mill charge Figure: Grinding media 441 Grinding Ball Charge in Mills: According to Levenson, the optimum grinding ball charge should be r 016D The degree of ball charge varies with in the limit of 25 and 45%Cement mill notebook SlideShareterms of energy requirements and steel consumption related to grinding media and liners Spherical grinding media are predominantly used in final stages of ore grinding The spherical balls change shape through breakage and wear Though this is universal in milling, its contribution and effect on milling kinetics, load behaviour and mill powerEFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL

03 Ball Mill EDM Mill (Grinding) Gear

Bulk weight of a grinding media charge in a two chamber mill with classifiying liner 35 HGRS TikariaMill Workshop SEPT07 Grinding Media (1st Compartment) partment Ø Ball [mm] Weight [ To really choose, I guess it depends on the material and your mill (vial, RPM, media, filling volume) Ie Si80Ge20 is easily alloyed in the high energy SPEX millBest way to determine the balltopowder ratio in ball Filling degree Chamber length Mill diameter Liner design and condition Mill speed Ball charge (filling degree composition) Liner design Intermediate diaphragm settings Mill ventilation 34 HGRS TikariaMill Workshop SEPT07 Grinding Media 4,4 [t/m3] 4,6 [t/m3] 4,7 [t/m3] Bulk weight of a grinding media charge in a two chamber mill with Ball mill understanding optimisation Mill (Grinding The entire filling of the grinding cylinders, which comprises the grinding media and the feed material, constantly receives impulses from the circular vibrations in the body of the mill The grinding action itself is produced by the rotation of the grinding media in the opposite direction to the driving rotation and by continuous headon Ball Mill an overview ScienceDirect TopicsApr 28, 2020 In January this year, we launched a new service on our website Therefore, for those of you who don’t know it yet, we recall that this service is intended for calculation of the filling degree the ball mill with grinding media You will receive accurate calculation of the filling degree the ball mill with grinding media at the following link and by filling in the proper fields as quickly as CALCULATION OF THE FILLING DEGREE THE BALL MILL WITH

A Volumetric Charge Measurement for Grinding Mills

Sep 01, 2004 In addition, the charge position must be such that the grinding media hits the charge toe and not the liners Therefore, a reliable online volumetric charge measurement is vital in the control and optimization of a grinding mill (Marklund and Oja, 1996; Dupont and Vien, 2001; van Nierop and Moys, 2001; Tano et aI, 2003) y, 90 x, o Charge The results obtained from this work show, the ball filling percentage variation is between 12– 37% which is lower than mill ball filling percentage, according to the designed conditions (15%) In addition, acquired load samplings result for mill ball filling was 13% Keywords: Miduk Copper oncentrator, SAG Mill, Ball Filling PercentageA Method to Determine the Ball Filling, in Miduk Copper Grinding Media The bulk densities of the steel media typically used are: Balls 4650 kg/m 3 Cylpebs 4700 kg/m 3 Rods 6247 kg/m 3 Cubes 5500 kg/m 3; For soft ore, ceramic media (90 °/o A l 2 0 3) can be used (2200 kg/m 3) Grinding media [images: mill media (13577)]AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Bulk weight of a grinding media charge in a two chamber mill with classifiying liner 35 HGRS TikariaMill Workshop SEPT07 Grinding Media (1st Compartment) partment Ø Ball [mm] Weight [ 03 Ball Mill EDM Mill (Grinding) Gear• Empty heights of both the chambers measured to calculate the ball charge, % filling and estimate the power consumption at mill shaft Based on the empty height measurements, charging of grinding media in Chambers I II calculated as equivalent to degree of filling of 22% 21% respectively The estimatedPROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

Ball mill understanding optimisation Mill (Grinding

Filling degree Chamber length Mill diameter Liner design and condition Mill speed Ball charge (filling degree composition) Liner design Intermediate diaphragm settings Mill ventilation 34 HGRS TikariaMill Workshop SEPT07 Grinding Media 4,4 [t/m3] 4,6 [t/m3] 4,7 [t/m3] Bulk weight of a grinding media charge in a two chamber mill with Jan 07, 2015 2 Shape, size, and weight of the grinding media 3 Friction between the lining and the grinding media 4 Internal friction mill charge Figure: Grinding media 441 Grinding Ball Charge in Mills: According to Levenson, the optimum grinding ball charge should be r 016D The degree of ball charge varies with in the limit of 25 and 45%Cement mill notebook SlideShareThe entire filling of the grinding cylinders, which comprises the grinding media and the feed material, constantly receives impulses from the circular vibrations in the body of the mill The grinding action itself is produced by the rotation of the grinding media in the opposite direction to the driving rotation and by continuous headon Ball Mill an overview ScienceDirect Topicsterms of energy requirements and steel consumption related to grinding media and liners Spherical grinding media are predominantly used in final stages of ore grinding The spherical balls change shape through breakage and wear Though this is universal in milling, its contribution and effect on milling kinetics, load behaviour and mill powerEFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL May 22, 2019 The larger the ball to material ratio, the higher the grinding efficiency But too high a ball ratio is unhelpful Because the amount of charge is reduced when the filling factor is constant, it is bound to reduce the productivity of the set, and sometimes reduce the alloy properties (Figure 82) The ball ratio is usually selected from 2:1 to 5:1The working principle of ball mill Meetyou Carbide

The Selection and Design of Mill Liners MillTraj

The second primary function of a liner is to transfer rotary motion of the mill to the grinding media and charge After all, it is the interface between the mill and the grinding charge Although work on the grinding action in mills was published 100 years ago (White 1905 and Davis 1919), the firstThe material charge is equally important in running an efficient milling operation If too little material is loaded with the media, it will mostly stay in the voids between the media and the media will just grind against each other Too little material will cause excessive wear on the media while grinding Page 1 Ball Milling TheoryAlthough the amount of the media charge is application dependent, a good rule of thumb to start with is 50% A good starting point for material loading is to have enough material in the mill to fill all of the voids and just cover the grinding media The point at which the charge breaks away from the periphery of the mill as it is carried upwardATTRITORS AND BALL MILLS HOW THEY WORK Robert E