Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

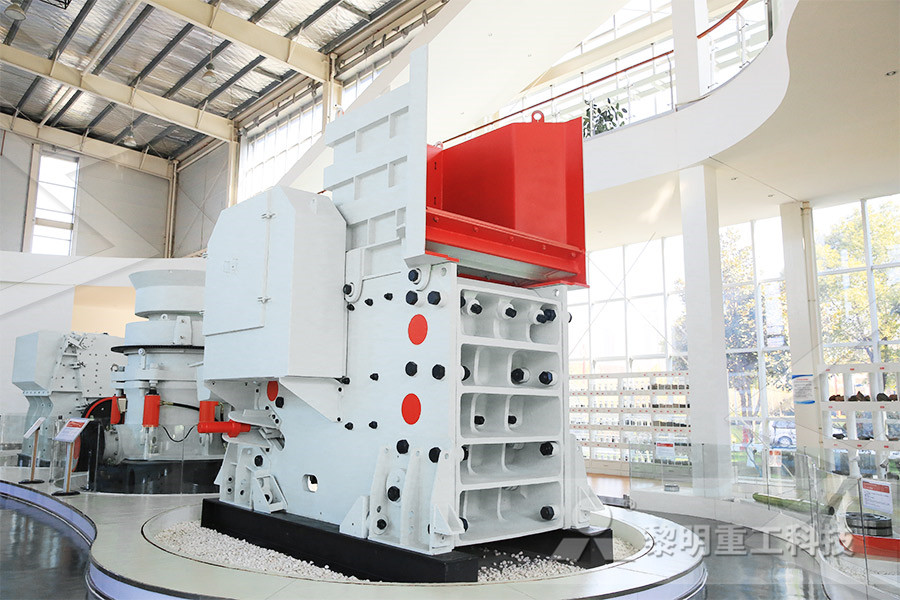

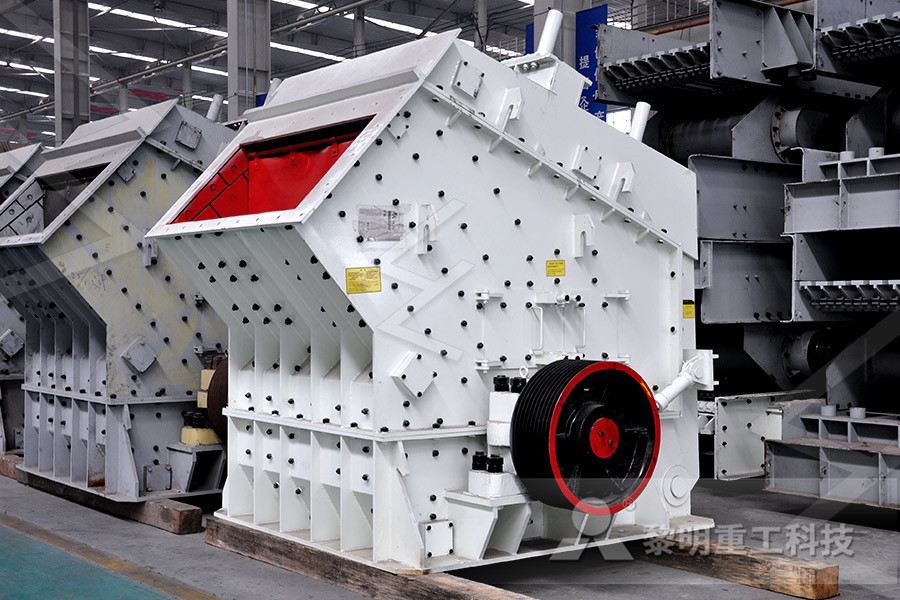

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Milling Speed and Feed Calculator

Milling Speed and Feed Calculator Determine the spindle speed (RPM) and feed rate (IPM) for a milling operation, as well as the cut time for a given cut length Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face millSpeed And Feed Calculators Ball Mill Finish Calculator Part Spacing Calculator G And M Code Characters Standard End Mill Sizes Standard Drill Sizes Drill And Counterbore Sizes Contact End Mill Speed Feed Calculator Tool Dia In Radial (Side) Depth of Cut This will adjust the feedrate if less than the tool rad In Num of Flutes Tool End Mill Speed and Feed Calculator Martin Chick AssociatesThe Speeds and Feeds Calculator may be employed for calculations of estimated speeds and feeds (RPM and IPM) values on the basis of the parameters you Speeds and Feeds Calculator Good CalculatorsEnter the No of Teeth and the Chip Load per Tooth to Determine the Feed Rate (In/Min) Use 002005 as starting chip load per toothSpeed and Feed Calculator Whitney Tool CompanyMilling Speed and Feed Calculator Determine the spindle speed (RPM) and feed rate (IPM) for a milling operation, as well as the cut time for a given cut length Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face millpcb end mill feed speed calculate

Speed and Feed Calculator Kennametal

Calculate Speed and Feed for Turning Applications These calculations are based upon theoretical values and are only intended for planning purposesF m = F t x NumTeeth x RPM, where F t is feed/tooth, and F m feed rateFeed Rate Calculator DaycounterCalculate RPM, IPM, SFM, IPT and more Below are variable abbreviations and formulas for many common milling operations Click here to download a printable PDF file containing these formulas Looking for speed feed calculators and recommendations for your Dapra tooling?Common Formulas for Milling Operations Speed, Feed, SFM Milling Speeds and Feeds Charts The most important aspect of milling with carbide end mills is to run the tool at the proper rpm and feed rate We have broken these recommendations down into material categories so you can make better decisions with how to productively run your end millsSpeeds And Feeds For Milling With End MillsCalculate Speed and Feed for Turning Applications These calculations are based upon theoretical values and are only intended for planning purposesSpeed and Feed Calculator Kennametal

Speeds And Feeds For Milling With End Mills

Milling Speeds and Feeds Charts The most important aspect of milling with carbide end mills is to run the tool at the proper rpm and feed rate We have broken these recommendations down into material categories so you can make better decisions with how to productively run your end millsHow to calculate feeds and speeds What I can do is show a formula that will give you a starting point from which you can adjust to suit your machine and the type of material you are milling Feeds and speeds formula First is the formula to find the RPM, RPM = SFM* X 382 / diameter of the tool (* SFM = Surface Feet per Minute)Learn Cnc Speeds Feeds with rpm feedrate calculatorEnd Mill Speeds and Feeds Calculator Milling Feeds and Speeds Spindle Speed Calculator Tool Diameter > inches Surface Speed: SFM (see table below for SFM values) To learn what is SFM and how to go from SFM to RPM, click this link Spindle Speed: > RPM Spindle RPM Formula = (12 * SurfacceSpeed) / (PI * CutterDiameter) Feed Rate Calculator Awesome! 2 Free Online Feed Rate Calculators [Mill, Lathe Calculate RPM, IPM, SFM, IPT and more Below are variable abbreviations and formulas for many common milling operations Click here to download a printable PDF file containing these formulas Looking for speed feed calculators and recommendations for your Dapra tooling?Common Formulas for Milling Operations Speed, Feed, SFM It can only cover 2 variables Our GWizard Feeds and Speeds Calculator covers 60 variables! When was the last time you looked through 30 charts to figure feeds and speeds? You basically can’t do it, which is why: – By far the most popular option is to use a Feeds Speeds Calculator Feeds and Speeds: The Definitive Guide (Updated for 2020)

SPEEDS AND FEEDS FOR CARBIDE ENDMILLS

speeds and feeds speeds and feeds for grooving tools material plastic magnesium aluminum copper brass bronze cast iron steel titanium stainless nickel monel inconel waspaloy hastelloy type teflon nylon phenolic glass filled az,am,ez,ze,hk 2021 thru 6061 101707 834978 gray ductile malleable 10051029 10301055 10601095 10l4510l50 12l1312l15 If doing this, it will be necessary to calculate the feed rate and speed instead of using the chart Example using a 1/4” or 0125” bit – Straight V Carbide Tipped Endmill SB# 13642: This bit is used for soft wood, at a depth of 1/2” (two times the diameter)Feeds and Speeds Charts ShopBotToolsCutting generates a lot of heat, making oil based coolant preferable Many machining spindles require 2000 rpm or more, to provide adequate cutting torque, which means that you have to use relatively small diameter end mills in order to end up with surface speeds this low If not using coolant, then max surface speed is 50 ft/min Insulation foamFablab Feeds and Speeds CalculatorSpeeds Feeds Solid Carbide High Performance End Mills Materials Soft Grades: Speed SFM Under 32 HRC: Materials Hard Grades: Speed SFM Over 32 HRC: Feed (Inch/Tooth) End Mill Diameter 1/8" 3/16" 1/4" 3/8" 1/2" 5/8" 3/4" 1" Recommendation for Coated Tools: NONFERROUS MATERIALS: Aluminum + Aluminum Alloys 2024T4/T6, 2014, 6061T6/T651 Speeds Feeds Niagara CutterMilling Drilling Reaming Top Turning speeds are adjusted to the feed rate of the mini lathe (0004/rev), a depth of cut of 0040, and a tool life of 180 minutes MaterialCutting Speeds LittleMachineShop

Speed Feed Recs Melin Tool Company

Millimeters Per Revolution (MMPR) — Feed rate of the cutter each revolution of the cutter In the metric system, the feed rate of the cutter can be calculated for each revolution of the cutter MMPR = Chip load x Number of flutes; Meters Per Minute (MPM) — The cutting speed of the end mill This system is used in all countries that use Cutting speed may or may not be a factor given to you by the toolmaker, it will depend on the material of the tool and the material of the part to be machined It may be given to you as a material removal rate (MRR), feed rate, or a feed per tooth, but we'll get to that laterMachining Calculators cutting, spindle, feed rate and Speed and Feed Calculator for Drilling and Milling,easyspeedsandfeeds is the easiest speeds and feed cacuator to C Speeds and Feeds Easy Speeds And FeedsIf doing this, it will be necessary to calculate the feed rate and speed instead of using the chart Example using a 1/4” or 0125” bit – Straight V Carbide Tipped Endmill SB# 13642: This bit is used for soft wood, at a depth of 1/2” (two times the diameter)Feeds and Speeds Charts ShopBotToolsCutting generates a lot of heat, making oil based coolant preferable Many machining spindles require 2000 rpm or more, to provide adequate cutting torque, which means that you have to use relatively small diameter end mills in order to end up with surface speeds this low If not using coolant, then max surface speed is 50 ft/min Insulation foamFablab Feeds and Speeds Calculator

Speed and Feed Calculators Redline Tools Redline Tools

If you are looking for detailed calculations regarding your project, use one of our feed or speed calculators listed below for accurate information every time Surface Feet Per Minute This calculates the Surface Feet Per Minute given the Diameter and Rotations Per MinuteThe calculator is intended to be a useful guide for you to use when calculating speeds and feeds Please remember that if you are using the higher RPM, the friction will give a better surface finish but can create more mechanical wear on the tool edge so you should always be aiming for the lowest RPM for that tool and materialSpeed and Feeds Calculator Tools Cutter ShopEquations and Explanation Behind this Calculator This calculator will determine speeds and feed rates for machining operations on mill or lathes Cutting speeds are usually given in feet or meters per minute and these speeds must be converted to spindle speeds, in revolutions per minute, to Machining Feeds and Speeds Calculator Engineers Edge Indexed End Mill Endmills with replaceable cutting edges and steel bodies These tools allow for higher cutting speeds due to shallow depths of cut and relative inexpensiveness of inserts High Feed End Mill Indexed end mill with an extremely low lead angle that directs most Download Speed And Feed Machinist Calculator Millimeters Per Revolution (MMPR) — Feed rate of the cutter each revolution of the cutter In the metric system, the feed rate of the cutter can be calculated for each revolution of the cutter MMPR = Chip load x Number of flutes; Meters Per Minute (MPM) — The cutting speed of the end mill This system is used in all countries that use Speed Feed Recs Melin Tool Company

Speeds and Feeds Easy Speeds And Feeds

Speed and Feed Calculator for Drilling and Milling,easyspeedsandfeeds is the easiest speeds and feed cacuator to useOct 02, 2017 Many tooling manufacturers provide useful speeds and feeds charts calculated specifically for their products For example, Harvey Tool provides the following chart for a 1/8” diameter end mill, tool #50308 A customer can find the SFM for the material on the left, in Speeds and Feeds 101 In The LoupeMilling Drilling Reaming Top Turning speeds are adjusted to the feed rate of the mini lathe (0004/rev), a depth of cut of 0040, and a tool life of 180 minutes MaterialCutting Speeds LittleMachineShopMaterial HB/Rc Speed SFM* Uncoated Speed SFM ALTiN+ Feed (Inches Per Tooth) Tool Diameter032056059090100190200350370595600+ Cast Iron: 160 HBThread Mill Feed and Speed Chart – Scientific Cutting The calculator will automatically provide the necessary speed and feed in the green fields For assistance setting up your milling program, contact a Dapra applications specialist or call (800) 2433344 Click here to download a chart of recommended Ball Nose cutting speeds and feeds (PDF)Ball Nose Finishing Mills Speed Feed Calculator DAPRA

cookbook Feeds and Speeds Tutorial

Calculating Feeds and Speeds: How do you calculate your feeds and speeds? (Hint: Use a state of the art Speeds and Feeds Calculator) Toolroom vs Manufacturing Feeds and Speeds: Do you know the difference between toolroom and manufacturing feeds and speeds? Coolant and Chip Clearing: Best practices for coolant and chip clearing on the millDec 24, 2010 Calculate Speeds and Feeds for 1/2" (05 inch) 2 flute end mill in Mild Steel at cutting speed = 100(ft/min), Chip Load=0001(inch per tooth) Calculating Spindle Speed (RPM): CodeGeneral Speeds and Feeds Formulas HSM Machining