Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

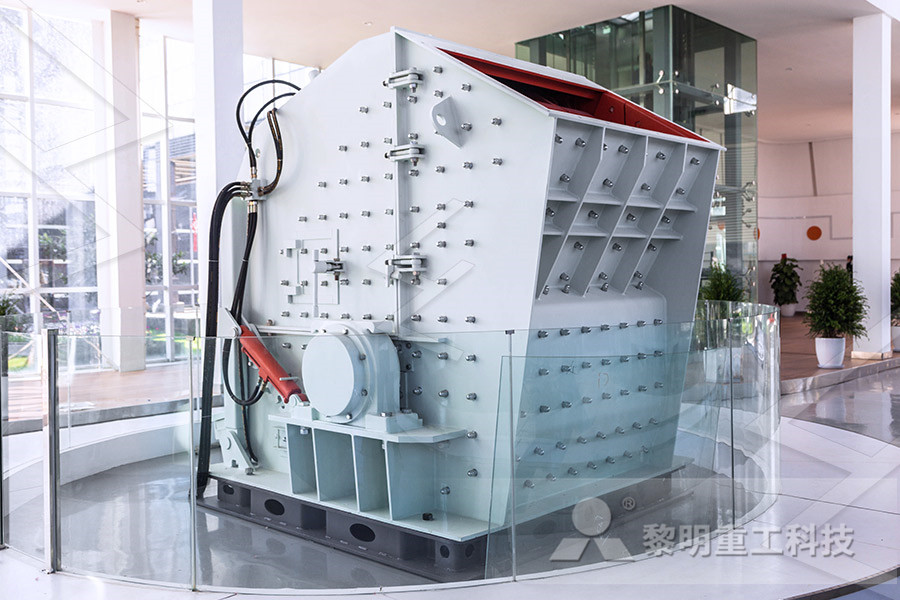

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at 2800 blaine I Nov 22, 2019 The report covers data on Grinding Mill Liner markets including historical and future trends for supply, prices, trading, competition, and value chain Additionally, the report also includes a SWOT analysis that concludes the strengths, weaknesses, opportunities, and threats impacting the segments of the overall marketGrinding Mill Liner Market 20202029 Outlines Of Cement Pfeiffer supply a grinding plant, consisting of an MVR vertical roller mill and a MultiDrive ® system, meeting the highest standards The Port Kembla plant is designed to produce 11 million tpa of slag and cement at about 4,000 cm²/g acc to BlaineReference report MVR vertical roller mill with MultiDrive Sep 18, 2013 If a cement producer can supply this test report, it is very useful, because the samples used are grab samples, not composites, and many are taken each month The test results give a good idea of how much a particular cement’s strengths vary on a shortterm basis and thus may be more useful than the standard mill certificateHow to Read a Cement Mill Certificate: Part 2 NPCAFigure 31: Typical Mimic sample of the Raw Mill Section 4 ENERGY SCENARIO 41 Electrical Energy System The cement plant receives electricity supply from the Captive Power Plant (CPP) (12 MW) and DG sets It is distributed to various sections of the plant An energy meter is installed on 110 kV feeder incomer, which recordsDETAILED ENERGY AUDIT AND CONSERVATION IN A CEMENT

Digital solutions for the cement industry Cement

The milling process in cement plants is extremely energyintensive there are potential energy savings available through the use of Mill Control System (MCS) The MCS is a software system that draws conclusions about the quality levels of the production plant through a knowledgebased approach using current plant data (defined measured values)The core of the ready2grind system is an MVR vertical mill, which comes equipped with four grinding rollers The scope of supply includes the ready2grind grinding system itself, from the feed bin to the filter discharge, as well as connected optional modules, such as product silos, a packing plant with truck bag loading and some other small extrasPetra Cement starts commercial operation of Gebr Pfeiffer millCompetence for the processes in the Cement Industry 6 The Cement Industry typically produces Portland cement – sometimes also masonry cement Portland cement is a fine, typically gray powder comprised of calcium (from lime), silicates, aluminates (argillaceous), and ferrites, with addition of sulfates Cement plants can operate continuously ): Automation solutions for the Cement Industryindustrial case study: the cement industry calmac study id: pge025101 final report prepared for pacific gas and electric company san francisco, california prepared by kema with assistance from lawrence berkeley national laboratory september 2005INDUSTRIAL CASE STUDY THE EMENT INDUSTRYDangote Cement is a vertically integrated cement company with complete Haulage needs met within the Group Right from the movement of raw material, fuel up to delivery of end product, Dangote Cement enjoys the benefit of its 3000 inhouse haulage fleet to ensure supply chain efficientlyOperation ::Welcome to Dangote Cement Plc::

Grinding Mill Liner Market 20202029 Outlines Of Cement

Nov 22, 2019 The report covers data on Grinding Mill Liner markets including historical and future trends for supply, prices, trading, competition, and value chain Additionally, the report also includes a SWOT analysis that concludes the strengths, weaknesses, opportunities, and threats impacting the segments of the overall marketSep 18, 2013 If a cement producer can supply this test report, it is very useful, because the samples used are grab samples, not composites, and many are taken each month The test results give a good idea of how much a particular cement’s strengths vary on a shortterm basis and thus may be more useful than the standard mill certificateHow to Read a Cement Mill Certificate: Part 2 NPCAPfeiffer supply a grinding plant, consisting of an MVR vertical roller mill and a MultiDrive ® system, meeting the highest standards The Port Kembla plant is designed to produce 11 million tpa of slag and cement at about 4,000 cm²/g acc to BlaineReference report MVR vertical roller mill with MultiDrive Figure 31: Typical Mimic sample of the Raw Mill Section 4 ENERGY SCENARIO 41 Electrical Energy System The cement plant receives electricity supply from the Captive Power Plant (CPP) (12 MW) and DG sets It is distributed to various sections of the plant An energy meter is installed on 110 kV feeder incomer, which recordsDETAILED ENERGY AUDIT AND CONSERVATION IN A Technical Report PDF Available DESIGN AND FABRICATION OF MINI BALL MILL METHODOLOGY In the cement grinding system, the quantity of raw material in the ball mill (PDF) DESIGN AND FABRICATION OF MINI BALL MILL

Digital solutions for the cement industry Cement

The milling process in cement plants is extremely energyintensive there are potential energy savings available through the use of Mill Control System (MCS) The MCS is a software system that draws conclusions about the quality levels of the production plant through a knowledgebased approach using current plant data (defined measured values)Competence for the processes in the Cement Industry 6 The Cement Industry typically produces Portland cement – sometimes also masonry cement Portland cement is a fine, typically gray powder comprised of calcium (from lime), silicates, aluminates (argillaceous), and ferrites, with addition of sulfates Cement plants can operate continuously ): Automation solutions for the Cement IndustryThe cement industry is one of the world’s largest industrial sources of CO2 emissions, accounting for 18 Gt/y in 2005, ie more than 6% of global emissions from the use of fossil fuels Over the years the cement industry has substantially reduced emissions of CO2 per tonne of cement by improved energyCO CAPTURE IN THE CEMENT INDUSTRYindustrial case study: the cement industry calmac study id: pge025101 final report prepared for pacific gas and electric company san francisco, california prepared by kema with assistance from lawrence berkeley national laboratory september 2005INDUSTRIAL CASE STUDY THE EMENT INDUSTRYAug 25, 2015 The Los Angeles Municipal Cement Mill By Randy Hees T he City of Los Angeles approved a bond for the construction a municipal aqueduct system in 1905 To supply the concreted needed for the project a cement plant was constructed near Sullivan on the Southern Pacific's Tehachapi Line, 1 mi (2km) east of Summit stationThe Los Angeles Municipal Cement Mill

What is the Material Test Report (MTR)/ Mill Test Report?

The material test report review in most of ITP’s is the “Review” point MTR based on EN 10204 Standard When you review the project specification even the inspection and test plan occasionally you might see that project requires the material test report being provided either in conformance with EN 10204 31 or EN 10204 32 EN 10204 31cement supply chain First, GrindtoOrder where cement is kept in clicker (intermediate product of the cement manufacturing process) and then grinded as orders appear Second, PacktoOrder, where cement is kept in bulk and then packed as orders appear Further research should be made to confirm the feasibility of these alternativesSupply Chain Management in the Cement IndustryDec 26, 2008 It can be from the mill itself if they have the equipment or by an outside company who tests for the mill 3 I can see where they might want a certificate showing what was used to make the PU coating or even a MSDS sheet from you the supplier but a MTR is just that, a MILL test report so sounds to me like they want it for the pipe 4What is a Mill Test Certificate? ASTM (testing materials Backed up by a workforce of professionals who are experts in all aspects of the design of cement plants, PENTA has the capabilities to develop complete projects from concept to commissioning PEC Consulting Group does the upfront scoping work and provides high level consulting services Since 1986, we have been providing consulting services to the []Cement Industry Minerals Industry Expertise from PEC Nov 22, 2019 The report covers data on Grinding Mill Liner markets including historical and future trends for supply, prices, trading, competition, and value chain Additionally, the report also includes a SWOT analysis that concludes the strengths, weaknesses, opportunities, and threats impacting the segments of the overall marketGrinding Mill Liner Market 20202029 Outlines Of Cement

Report on Cement manufacturing process

Jul 08, 2016 Industrial Internship Training Report 201516 26 Cement mill A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills, which are more effective than ball millsPfeiffer supply a grinding plant, consisting of an MVR vertical roller mill and a MultiDrive ® system, meeting the highest standards The Port Kembla plant is designed to produce 11 million tpa of slag and cement at about 4,000 cm²/g acc to BlaineReference report MVR vertical roller mill with MultiDrive cement supply chain First, GrindtoOrder where cement is kept in clicker (intermediate product of the cement manufacturing process) and then grinded as orders appear Second, PacktoOrder, where cement is kept in bulk and then packed as orders appear Further research should be made to confirm the feasibility of these alternativesSupply Chain Management in the Cement IndustryThe utility model discloses a medicine adding system used for a cement dualpressure waste heat power station, which comprises a phosphate solution tank The medicine adding system used for the cement dualpressure waste heat power station is characterized in that one end of the phosphate solution tank is provided with an artificial medicine adding hole; the other end of the phosphate CNU Medicine adding system used for cement dual Competence for the processes in the Cement Industry 6 The Cement Industry typically produces Portland cement – sometimes also masonry cement Portland cement is a fine, typically gray powder comprised of calcium (from lime), silicates, aluminates (argillaceous), and ferrites, with addition of sulfates Cement plants can operate continuously ): Automation solutions for the Cement Industry

What is the Material Test Report (MTR)/ Mill Test Report?

The material test report review in most of ITP’s is the “Review” point MTR based on EN 10204 Standard When you review the project specification even the inspection and test plan occasionally you might see that project requires the material test report being provided either in conformance with EN 10204 31 or EN 10204 32 EN 10204 31The cement industry is one of the world’s largest industrial sources of CO2 emissions, accounting for 18 Gt/y in 2005, ie more than 6% of global emissions from the use of fossil fuels Over the years the cement industry has substantially reduced emissions of CO2 per tonne of cement by improved energyCO CAPTURE IN THE CEMENT INDUSTRYBacked up by a workforce of professionals who are experts in all aspects of the design of cement plants, PENTA has the capabilities to develop complete projects from concept to commissioning PEC Consulting Group does the upfront scoping work and provides high level consulting services Since 1986, we have been providing consulting services to the []Cement Industry Minerals Industry Expertise from PEC Dec 26, 2008 It can be from the mill itself if they have the equipment or by an outside company who tests for the mill 3 I can see where they might want a certificate showing what was used to make the PU coating or even a MSDS sheet from you the supplier but a MTR is just that, a MILL test report so sounds to me like they want it for the pipe 4What is a Mill Test Certificate? ASTM (testing materials Cement Manufacturers Association (CMA) is the apex body of large (1 million tonnes capacity per annum and more) cement manufacturers in India It plays a catalytic role in bridging the gap between the government and the Indian Cement Industry towards shaping important policy matters in relation to cementCMA India Cement Manufacturers Association in India

cement plant equipments manufacturer and suppliers of

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD productionCement MIS Archives (compressed files, zip) 19651969 19701974 19751979 19801989 19901994 19951999 20002004 20052009 20102014 20152017 2018 US Production of Selected Mineral Commodities (Quarterly Mineral Industry Surveys) Annual Publications Mineral Commodity Summaries Cement PDF Format:Cement Statistics and Information USGSROLLER MILL Used in cement industry Vertical Mills used for Pregrinding of clinker (lumps to coarse powder) Finish grinding (lumps to powder) of Coal/Petcoke for kiln Raw materials for kiln Cement, OPC or mixed Slag, pure or mixed VRM Functions Vertical Roller Mill (VRM) Details feed gate (air lock) mill casing water injection dam ring louvre ring nozzle of material scraper mill outlet Vrm Presentation Mill (Grinding) Cement