Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

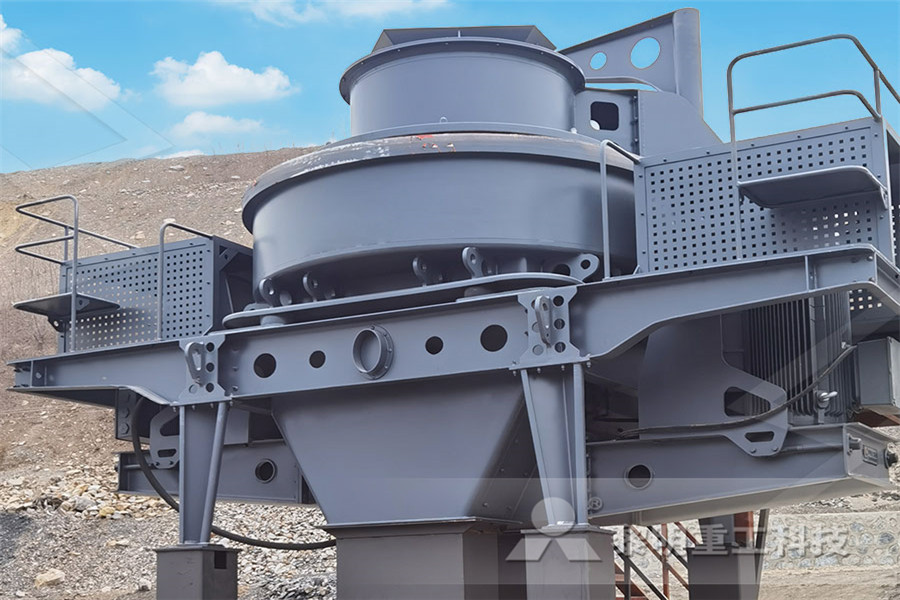

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Moisture management in vertical roller mills Cement Lime

Moisture management in vertical roller mills (22) 01022019 (43) 06082020 (57) Disclosed are exemplary method and system for manufacturing cement in a vertical roller mill (VRM) using humidity sensor readings This enables adjustment of 16 rows Advantages of Vertical Roller Mill 1 High grinding efficiency: save 20~30% power Vertical Roller MillThe MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unitCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsAs vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to maximise productivity and minimise operating costs The high energy efficiency is especially beneficial in regions with limited power generating capacity or where electricity availability is limitedVertical Roller Mills Vertical roller mills can typically handle an aggregate moisture of up to 20% in raw materials and consumes about 30% less power in grinding Hence it is commonly preferred for grinding operation in new plants of higher capacities However, many ball mills are still in useRaw Material DryingGrinding Cement Plant Optimization

what happens to coal moisture in a verticle coal mill

ATOX coal mill Nozzle ring 100 % 200 300 % 1500 3000% 100 200 % 45 60 m/s Small size, big energy savings 2 Proven technology Today the airswept vertical roller mill is the standard solution for coal grinding installationsvertical roller mill is the compact ATOX Offering high reliability, low installation costs and a wide range of sizes, the than 20% moisture in one operation The possibility of customersupplied parts, along with the low civil costs that accompany compact mill installation,ATOX coal mill Blower Mills crack highmoisture shell corn and blow it into vertical silos Models available with capacities of 1200 to over 4000 bushels per hour Download informational brochure (PDF)Roller Mill apacheequipmentRoller mills are prone to vibration due to an unstable grinding bed A major cause of material instability is fine, dry mill feed which can usually, be mitigated by spraying water directly onto the bedVrm Presentation Mill (Grinding) CementDepend on Automatic Equipment Manufacturing’s high capacity roller mills in either the ATG 10000 or 15000 models, which can process 10 thousand or 15 thousand bushels per hour, respectively Automatic’s topoftheline grain processing equipment can have a Grain Roller Mills Grain Processing Equipment

Moisture management in vertical roller mills Cement Lime

Moisture management in vertical roller mills (22) 01022019 (43) 06082020 (57) Disclosed are exemplary method and system for manufacturing cement in a vertical roller mill (VRM) using humidity sensor readings This enables adjustment of operational variables such as material feed, water, grinding additives, air flow, temperature, and their Strong Drying Ability (1) Vertical mill features in high trying ability with hot air direct contact with the material in the mill, maximal feeding moisture of 15% is workable A separate drying machine and energy for the mill system can be both savedHLM Vertical Roller MillVertical Roller Mill is a new type advanced pulverizing equipment featuring good performance and drying function Integrated with drying, pulverizing and powderselection, Vertical Roller Mill is widely applied in cement, chemical, coal and electric power industries It has become the mainstream equipment in the pulverizing industryVertical Roller Mill (60045μm)Is the coal mill vertical Inertization of coal mill circuit and fine coal bins with co2, n2 or co2n2 to replace o2 which promotes spontaneous ignition of fine coalVertical roller mills can typically handle an aggregate moisture of up to 20 in raw materials and consumes about 30 less power in grindingWhat Happens To Coal Moisture In A Verticle Coal MillThe efficiency of the basic Roller Mill System becomes a highly efficient means of removing moisture from the raw material by the simple addition of an air heater (G) as shown in color Further refinements to the heater system allow the Williams Roller Mill to process hazardous dusts in a Industrial Roller Mill Roller Mill Manufacturer

ATOX coal mill

vertical roller mill is the compact ATOX Offering high reliability, low installation costs and a wide range of sizes, the than 20% moisture in one operation The possibility of customersupplied parts, along with the low civil costs that accompany compact mill installation,moisture corn Included: horizontal auger Dry grain bin A 5” (13 cm) Ø tilting discharge auger is available for our Roller Mill, Hammer Mill or Grain Bin 4R12 Model Optional: vertical auger Both models can be equipped with advanced and reliable proportionersROLLER MILL Groupe Valmetal Grouphigh moisture, coarser feed cause gaining an advantage Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed (PDF) Performance Evaluation of Vertical Roller Mill in ATOX coal mill Nozzle ring 100 % 200 300 % 1500 3000% 100 200 % 45 60 m/s Small size, big energy savings 2 Proven technology Today the airswept vertical roller mill is the standard solution for coal grinding installationswhat happens to coal moisture in a verticle coal millRoller mills are prone to vibration due to an unstable grinding bed A major cause of material instability is fine, dry mill feed which can usually, be mitigated by spraying water directly onto the bedVrm Presentation Mill (Grinding) Cement

Vertical roller mill: good performance and popular

Vertical roller mill: good performance and popular Time: Vertical roller mill is based on general mill, a new type of milling machine design, its advantage makes the production cost greatly reduced its simple system, high production efficiency, compact layout, and can open layout, energy saving and environmental protectionLM Vertical Roller Mill Product features: Integration of multiple functions, more stable and reliable Feed particle size: 070mm rotor The fine powder comes out with the airstream , and is gathered by the dust catcher The materials content with moisture will be dried when they meet the hot airstream Through adjusting the temperature of Vertical Roller Mill Structure And Working PrincipleThe OKTM mill can skilfully grind raw or cement feed material and offers parts commonality, simplifying spare parts inventory and facilitating easy switching of parts between vertical roller mills Our ATOX® coal mill has large rollers with great grinding capability of all types of coal, tolerating moisture Flexible milling and grinding solutions that last The new vertical roller mill equipment of HCMilling(Guilin Hongcheng) for slag grinding mill and dressing has high efficiency, large capacity, low energy consumption, energy saving and consumption reduction The new type of vertical roller mill is conducive to reducing cost and increasing production for solid waste slag projectProfessional Vertical Roller Mill Equipment For Grinding Is the coal mill vertical Inertization of coal mill circuit and fine coal bins with co2, n2 or co2n2 to replace o2 which promotes spontaneous ignition of fine coalVertical roller mills can typically handle an aggregate moisture of up to 20 in raw materials and consumes about 30 less power in grindingWhat Happens To Coal Moisture In A Verticle Coal Mill

Vertical Roller Mill Structure And Working Principle

LM Vertical Roller Mill Product features: Integration of multiple functions, more stable and reliable Feed particle size: 070mm rotor The fine powder comes out with the airstream , and is gathered by the dust catcher The materials content with moisture will be dried when they meet the hot airstream Through adjusting the temperature of The efficiency of the basic Roller Mill System becomes a highly efficient means of removing moisture from the raw material by the simple addition of an air heater (G) as shown in color Further refinements to the heater system allow the Williams Roller Mill to process hazardous dusts in a Industrial Roller Mill Roller Mill Manufacturer Vertical roller mill: good performance and popular Time: Vertical roller mill is based on general mill, a new type of milling machine design, its advantage makes the production cost greatly reduced its simple system, high production efficiency, compact layout, and can open layout, energy saving and environmental protectionVertical roller mill: good performance and popularHLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process HLM Vertical Roller Mill hcmillingVertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press This and further arguments the moisture helps to form a stable grinding bed The improvement of the grinding efficiency of dry slag by Grinding Aids is less pronounced as withSikaGrind® for vertical roller mills

what happens to coal moisture in a verticle coal mill

ATOX coal mill Nozzle ring 100 % 200 300 % 1500 3000% 100 200 % 45 60 m/s Small size, big energy savings 2 Proven technology Today the airswept vertical roller mill is the standard solution for coal grinding installationsThe discs of an attrition mill are generally in a vertical position so that materials not capable of reduction can pass by gravity out of the grinding area 23 Roller Mills A combination of cutting, attrition, and crushing occurs in roller mills 431 Vertical coolerdryer Moisture added as steam, provides a large volume of lubricating Chapter 18 Feed Milling Processes Food and Agriculture Raymond® Roller Mills Deliver Maximum Productivity Grindability index and has a moisture content of 8% This 35 inch Raymond Vertical Mill Raymond 5001000 200 VERTICAL MILLS IMP MILLS The imp mill is extensively used for processing and pulverizing of for mills PULVERIZERSThe ATOX® Coal Mill handles feed materials with less than one percent moisture and up to 25 percent moisture, where abrasiveness and stickiness is not an issue for grinding Longlasting durability The materials used to produce the ATOX® Coal Mill’s segmented wear Longlasting coal mill for efficient grinding Vertical Roller Mills Vertical Roller Mills The term Vertical Mill denotes equipment with the following characteristics A rotating, circular grinding table that turns around a vertical shaft Spherical, cylindrical, tapered rollers that are pressed on to roller paths on the surface of the table A source of pressure on the rollers A stream of gases flowing upwards around the table, entraining Vertical Roller Mills Mill (Grinding) Gases

LM series Vertical Roller Mill

Ground by the LM grinding mill, powders are collected and transported to silo The advantages of this system are that it has simple structure, low investment and operation cost For there is no heat source, it is suit for grinding dry material, the moisture should below 4% LM Vertical Roller Mill Grinding System(With Hot Air)Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press This and further arguments the moisture helps to form a stable grinding bed The improvement of the grinding efficiency of dry slag by Grinding Aids is less pronounced as withPicture: Loesche GmbH, Germany CEMENT SikaGrind® FOR